Основной каталог Kyocera 2016-2017 - страница 526

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

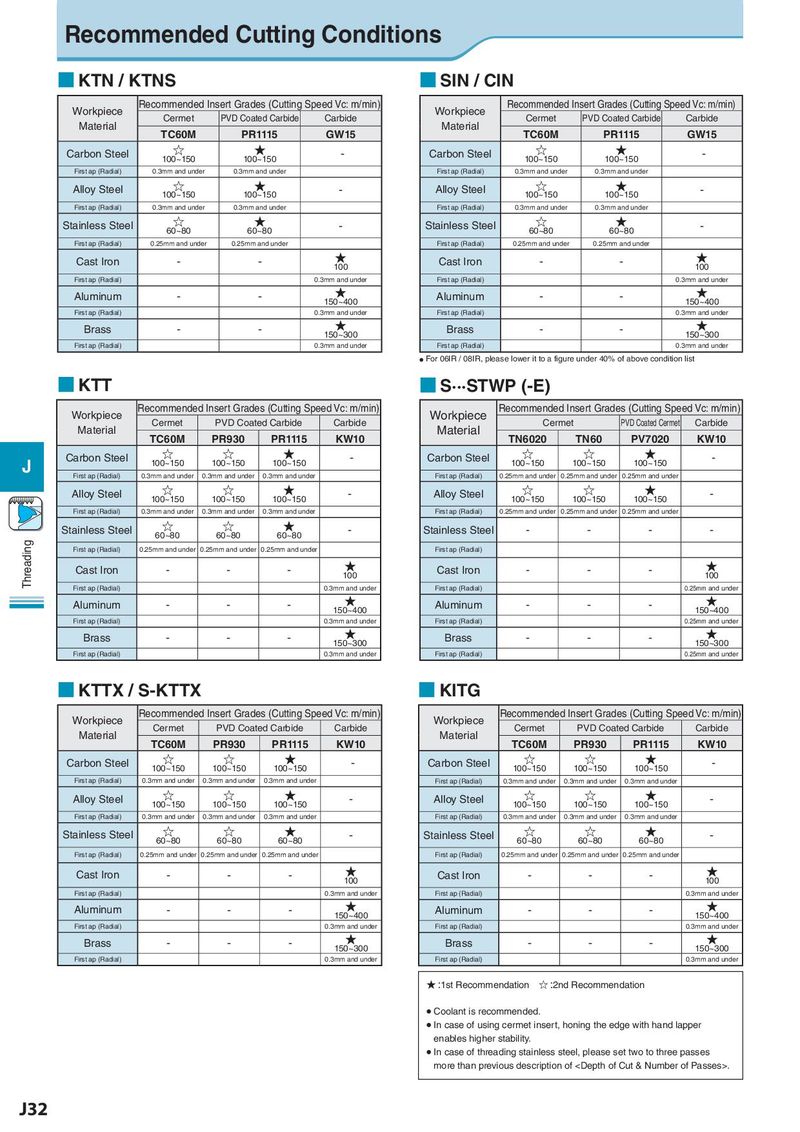

Recommended Cutting Conditions

■ KTN / KTNS ■ SIN / CIN

Workpiece Recommended Insert Grades (Cutting Speed Vc: m/min) Workpiece Recommended Insert Grades (Cutting Speed Vc: m/min)

Material Cermet PVD Coated Carbide Carbide Material Cermet PVD Coated Carbide Carbide

TC60M PR1115 GW15 TC60M PR1115 GW15

Carbon Steel ☆ ★ - Carbon Steel ☆ ★ -

100~150 100~150 100~150 100~150

First ap (Radial) 0.3mm and under 0.3mm and under First ap (Radial) 0.3mm and under 0.3mm and under

Alloy Steel ☆ ★ - Alloy Steel ☆ ★ -

100~150 100~150 100~150 100~150

First ap (Radial) 0.3mm and under 0.3mm and under First ap (Radial) 0.3mm and under 0.3mm and under

Stainless Steel ☆ ★ - Stainless Steel ☆ ★ -

60~80 60~80 60~80 60~80

First ap (Radial) 0.25mm and under 0.25mm and under First ap (Radial) 0.25mm and under 0.25mm and under

Cast Iron - - ★ Cast Iron - - ★

100 100

First ap (Radial) 0.3mm and under First ap (Radial) 0.3mm and under

Aluminum - - ★ Aluminum - - ★

150~400 150~400

First ap (Radial) 0.3mm and under First ap (Radial) 0.3mm and under

Brass - - ★ Brass - - ★

150~300 150~300

First ap (Radial) 0.3mm and under First ap (Radial) 0.3mm and under

● For 06IR / 08IR, please lower it to a figure under 40% of above condition list

■ KTT ■ S···STWP (-E)

Workpiece Recommended Insert Grades (Cutting Speed Vc: m/min) Workpiece Recommended Insert Grades (Cutting Speed Vc: m/min)

Material Cermet PVD Coated Carbide Carbide Material Cermet PVD Coated Cermet Carbide

TC60M PR930 PR1115 KW10 TN6020 TN60 PV7020 KW10

Carbon Steel ☆ ☆ ★ - Carbon Steel ☆ ☆ ★ -

100~150 100~150 100~150 100~150 100~150 100~150

J

First ap (Radial) 0.3mm and under 0.3mm and under 0.3mm and under First ap (Radial) 0.25mm and under 0.25mm and under 0.25mm and under

Alloy Steel ☆ ☆ ★ - Alloy Steel ☆ ☆ ★ -

100~150 100~150 100~150 100~150 100~150 100~150

First ap (Radial) 0.3mm and under 0.3mm and under 0.3mm and under First ap (Radial) 0.25mm and under 0.25mm and under 0.25mm and under

Stainless Steel ☆ ☆ ★ - Stainless Steel - - - -

60~80 60~80 60~80

Threading First ap (Radial) 0.25mm and under 0.25mm and under 0.25mm and under First ap (Radial)

Cast Iron - - - ★ Cast Iron - - - ★

100 100

First ap (Radial) 0.3mm and under First ap (Radial) 0.25mm and under

Aluminum - - - ★ Aluminum - - - ★

150~400 150~400

First ap (Radial) 0.3mm and under First ap (Radial) 0.25mm and under

Brass - - - ★ Brass - - - ★

150~300 150~300

First ap (Radial) 0.3mm and under First ap (Radial) 0.25mm and under

■ KTTX / S-KTTX ■ KITG

Workpiece Recommended Insert Grades (Cutting Speed Vc: m/min) Workpiece Recommended Insert Grades (Cutting Speed Vc: m/min)

Material Cermet PVD Coated Carbide Carbide Material Cermet PVD Coated Carbide Carbide

TC60M PR930 PR1115 KW10 TC60M PR930 PR1115 KW10

Carbon Steel ☆ ☆ ★ - Carbon Steel ☆ ☆ ★ -

100~150 100~150 100~150 100~150 100~150 100~150

First ap (Radial) 0.3mm and under 0.3mm and under 0.3mm and under First ap (Radial) 0.3mm and under 0.3mm and under 0.3mm and under

Alloy Steel ☆ ☆ ★ - Alloy Steel ☆ ☆ ★ -

100~150 100~150 100~150 100~150 100~150 100~150

First ap (Radial) 0.3mm and under 0.3mm and under 0.3mm and under First ap (Radial) 0.3mm and under 0.3mm and under 0.3mm and under

Stainless Steel ☆ ☆ ★ - Stainless Steel ☆ ☆ ★ -

60~80 60~80 60~80 60~80 60~80 60~80

First ap (Radial) 0.25mm and under 0.25mm and under 0.25mm and under First ap (Radial) 0.25mm and under 0.25mm and under 0.25mm and under

Cast Iron - - - ★ Cast Iron - - - ★

100 100

First ap (Radial) 0.3mm and under First ap (Radial) 0.3mm and under

Aluminum - - - ★ Aluminum - - - ★

150~400 150~400

First ap (Radial) 0.3mm and under First ap (Radial) 0.3mm and under

Brass - - - ★ Brass - - - ★

150~300 150~300

First ap (Radial) 0.3mm and under First ap (Radial) 0.3mm and under

★ :1st Recommendation ☆ :2nd Recommendation

● Coolant is recommended.

●In case of using cermet insert, honing the edge with hand lapper

enables higher stability.

●In case of threading stainless steel, please set two to three passes

more than previous description of