Основной каталог Kyocera 2016-2017 - страница 492

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

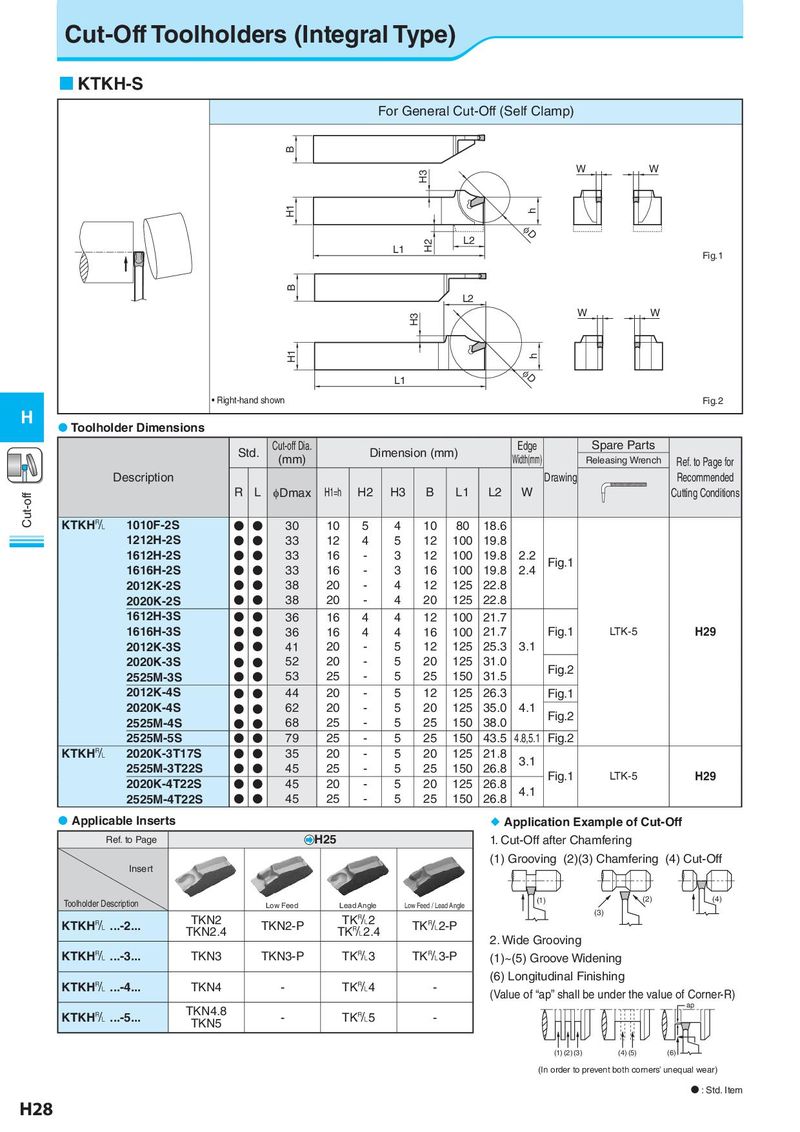

Cut-Off Toolholders (Integral Type) KTKH-S For General Cut-Off (Self Clamp) B H3 W W H1 h φD L1 H2 L2 Fig.1 B L2 H3 W W H1 h L1 φD • Right-hand shown Fig.2 H Toolholder Dimensions Std. Cut-off Dia. Dimension (mm) Edge Spare Parts (mm) Width(mm) Releasing Wrench Ref. to Page for Description Drawing Recommended Cut-off R L φDmax H1=h H2 H3 B L1 L2 W Cutting Conditions KTKH& 1010F-2S ● ● 30 10 5 4 10 80 18.6 1212H-2S ● ● 33 12 4 5 12 100 19.8 1612H-2S ● ● 33 16 - 3 12 100 19.8 2.2 Fig.1 1616H-2S ● ● 33 16 - 3 16 100 19.8 2.4 2012K-2S ● ● 38 20 - 4 12 125 22.8 2020K-2S ● ● 38 20 - 4 20 125 22.8 1612H-3S ● ● 36 16 4 4 12 100 21.7 1616H-3S ● ● 36 16 4 4 16 100 21.7 Fig.1 LTK-5 H29 2012K-3S ● ● 41 20 - 5 12 125 25.3 3.1 2020K-3S ● ● 52 20 - 5 20 125 31.0 Fig.2 2525M-3S ● ● 53 25 - 5 25 150 31.5 2012K-4S ● ● 44 20 - 5 12 125 26.3 Fig.1 2020K-4S ● ● 62 20 - 5 20 125 35.0 4.1 Fig.2 2525M-4S ● ● 68 25 - 5 25 150 38.0 2525M-5S ● ● 79 25 - 5 25 150 43.5 4.8,5.1 Fig.2 KTKH& 2020K-3T17S ● ● 35 20 - 5 20 125 21.8 3.1 2525M-3T22S ● ● 45 25 - 5 25 150 26.8 Fig.1 LTK-5 H29 2020K-4T22S ● ● 45 20 - 5 20 125 26.8 4.1 2525M-4T22S ● ● 45 25 - 5 25 150 26.8 Applicable Inserts Application Example of Cut-Off Ref. to Page H25 1. Cut-Off after Chamfering (1) Grooving (2)(3) Chamfering (4) Cut-Off Insert Toolholder Description Low Feed Lead Angle Low Feed / Lead Angle (1) (1) (1) (2) (2) (2) (4) (4) (4) TKN2 TK&2 (3) (3) (3) KTKH& ...-2... TKN2.4 TKN2-P TK&2.4 TK&2-P 2. Wide Grooving KTKH& ...-3... TKN3 TKN3-P TK&3 TK&3-P (1)~(5) Groove Widening KTKH& ...-4... TKN4 - TK&4 - (6) Longitudinal Finishing (Value of “ap” shall be under the value of Corner-R) TKN4.8 ap KTKH& ...-5... TKN5 - TK&5 - (1) (2) (3) (4) (5) (6) (In order to prevent both corners’ unequal wear) N : Std. Item H28