Основной каталог Kyocera 2016-2017 - страница 464

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

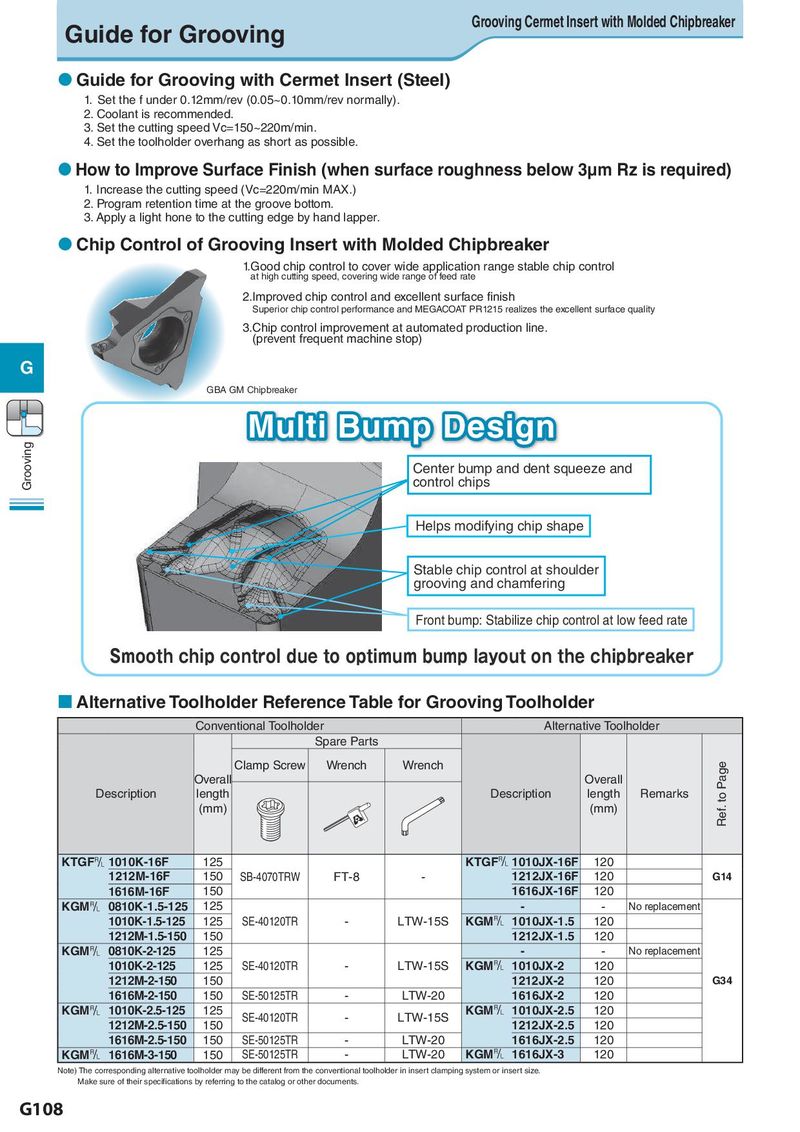

Guide for Grooving Grooving Cermet Insert with Molded Chipbreaker Guide for Grooving with Cermet Insert (Steel) 1. Set the f under 0.12mm/rev (0.05~0.10mm/rev normally). 2. Coolant is recommended. 3. Set the cutting speed Vc=150~220m/min. 4. Set the toolholder overhang as short as possible. How to Improve Surface Finish (when surface roughness below 3μm Rz is required) 1. Increase the cutting speed (Vc=220m/min MAX.) 2. Program retention time at the groove bottom. 3. Apply a light hone to the cutting edge by hand lapper. Chip Control of Grooving Insert with Molded Chipbreaker 1.Good chip control to cover wide application range stable chip control at high cutting speed, covering wide range of feed rate 2.Improved chip control and excellent surface finish Superior chip control performance and MEGACOAT PR1215 realizes the excellent surface quality 3.Chip control improvement at automated production line. (prevent frequent machine stop) G GBA GM Chipbreaker Grooving Multi Bump Design Center bump and dent squeeze and control chips Helps modifying chip shape Stable chip control at shoulder grooving and chamfering Front bump: Stabilize chip control at low feed rate Smooth chip control due to optimum bump layout on the chipbreaker Alternative Toolholder Reference Table for Grooving Toolholder Conventional Toolholder Alternative Toolholder Spare Parts Clamp Screw Wrench Wrench Ref. to Page Overall Overall Description length Description length Remarks (mm) (mm) KTGF& 1010K-16F 125 KTGF& 1010JX-16F 120 1212M-16F 150 SB-4070TRW FT-8 - 1212JX-16F 120 G14 1616M-16F 150 1616JX-16F 120 KGM& 0810K-1.5-125 125 - - No replacement 1010K-1.5-125 125 SE-40120TR - LTW-15S KGM& 1010JX-1.5 120 1212M-1.5-150 150 1212JX-1.5 120 KGM& 0810K-2-125 125 - - No replacement 1010K-2-125 125 SE-40120TR - LTW-15S KGM& 1010JX-2 120 1212M-2-150 150 1212JX-2 120 G34 1616M-2-150 150 SE-50125TR - LTW-20 1616JX-2 120 KGM& 1010K-2.5-125 125 SE-40120TR - LTW-15S KGM& 1010JX-2.5 120 1212M-2.5-150 150 1212JX-2.5 120 1616M-2.5-150 150 SE-50125TR - LTW-20 1616JX-2.5 120 KGM& 1616M-3-150 150 SE-50125TR - LTW-20 KGM& 1616JX-3 120 Note) The corresponding alternative toolholder may be different from the conventional toolholder in insert clamping system or insert size. Make sure of their specifications by referring to the catalog or other documents. G108