Основной каталог Kyocera 2016-2017 - страница 430

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

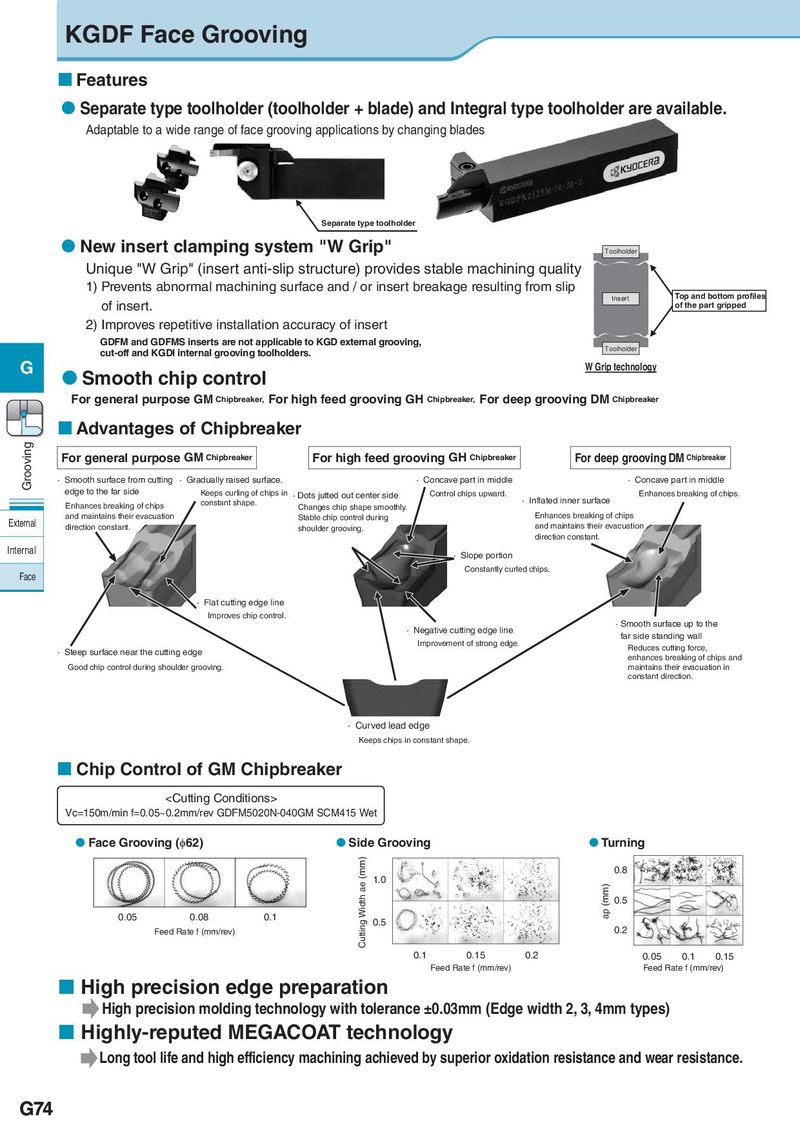

KGDF Face Grooving

Features

Separate type toolholder (toolholder + blade) and Integral type toolholder are available.

Adaptable to a wide range of face grooving applications by changing blades

Separate type toolholder

New insert clamping system "W Grip" Toolholder

Unique "W Grip" (insert anti-slip structure) provides stable machining quality

1) Prevents abnormal machining surface and / or insert breakage resulting from slip Top and bottom profiles

of insert. Insert

of the part gripped

2) Improves repetitive installation accuracy of insert

GDFM and GDFMS inserts are not applicable to KGD external grooving, Toolholder

cut-off and KGDI internal grooving toolholders.

G Smooth chip control W Grip technology

For general purpose GM Chipbreaker, For high feed grooving GH Chipbreaker, For deep grooving DM Chipbreaker

Advantages of Chipbreaker

Grooving For general purpose GM Chipbreaker For high feed grooving GH Chipbreaker For deep grooving DM Chipbreaker

· Smooth surface from cutting · Gradually raised surface. · Concave part in middle · Concave part in middle

edge to the far side Keeps curling of chips in · Dots jutted out center side Control chips upward. Enhances breaking of chips.

Enhances breaking of chips constant shape. Changes chip shape smoothly. · Inflated inner surface

External and maintains their evacuation Stable chip control during Enhances breaking of chips

direction constant. shoulder grooving. and maintains their evacuation

direction constant.

Internal · Slope portion

Face Constantly curled chips.

· Flat cutting edge line

Improves chip control.

· Negative cutting edge line · Smooth surface up to the

Improvement of strong edge. far side standing wall

· Steep surface near the cutting edge Reduces cutting force,

enhances breaking of chips and

Good chip control during shoulder grooving. maintains their evacuation in

constant direction.

· Curved lead edge

Keeps chips in constant shape.

Chip Control of GM Chipbreaker