Основной каталог Kyocera 2016-2017 - страница 420

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

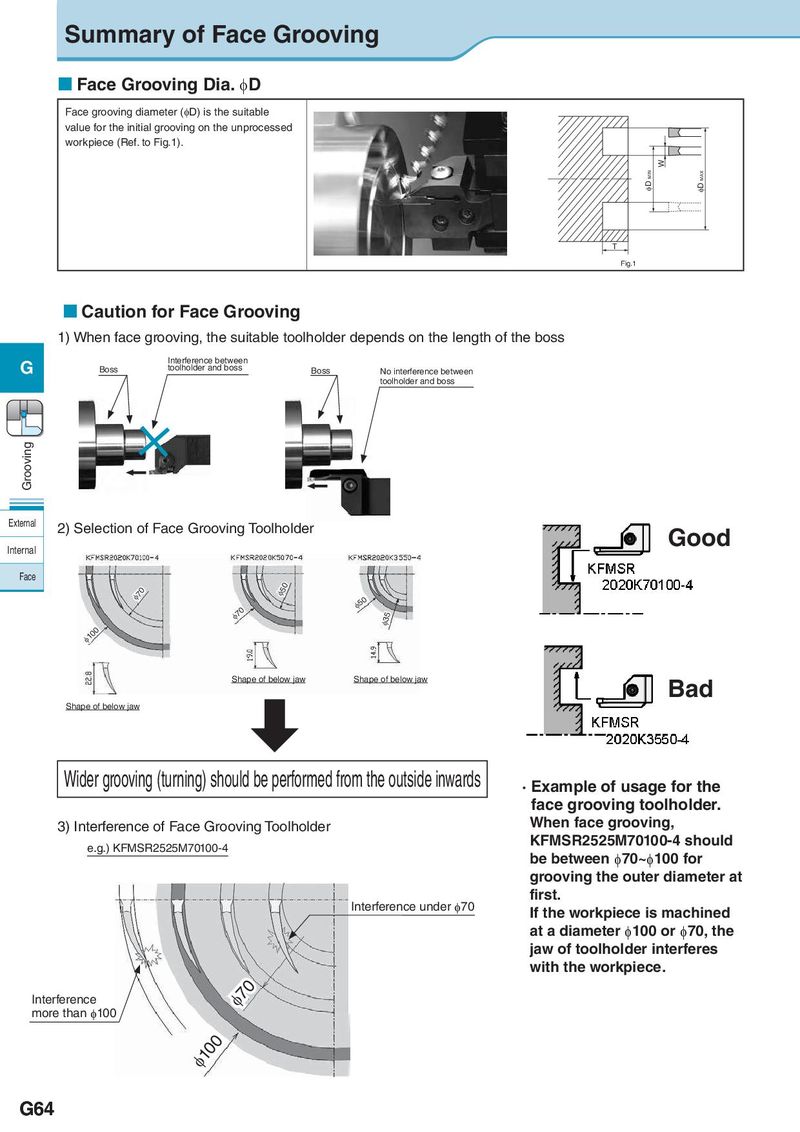

Summary of Face Grooving Face Grooving Dia. φD Face grooving diameter (φD) is the suitable value for the initial grooving on the unprocessed workpiece (Ref. to Fig.1). W ID MIN ID MAX T Fig.1 Caution for Face Grooving 1) When face grooving, the suitable toolholder depends on the length of the boss G Interference between toolholder and boss Boss Boss No interference between toolholder and boss Grooving External 2) Selection of Face Grooving Toolholder Good Internal Face φ70 φ50 φ70 φ50 φ35 φ100 Shape of below jaw Shape of below jaw Bad Shape of below jaw Wider grooving (turning) should be performed from the outside inwards · Example of usage for the face grooving toolholder. 3) Interference of Face Grooving Toolholder When face grooving, e.g.) KFMSR2525M70100-4 KFMSR2525M70100-4 should be between φ70~φ100 for grooving the outer diameter at Interference under φ70 first. If the workpiece is machined at a diameter φ100 or φ70, the jaw of toolholder interferes with the workpiece. Interference φ70 more than φ100 φ100 G64