Основной каталог Kyocera 2016-2017 - страница 408

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

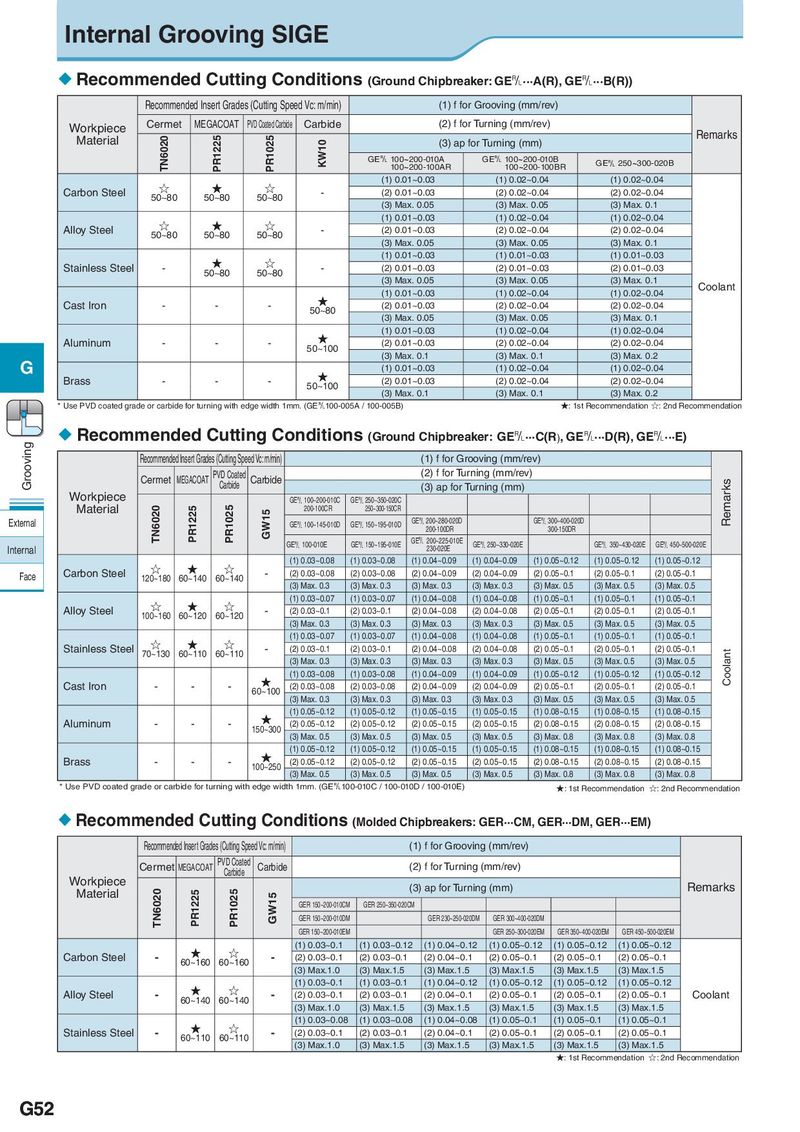

Internal Grooving SIGE Recommended Cutting Conditions (Ground Chipbreaker: GE&···A(R), GE&···B(R)) Recommended Insert Grades (Cutting Speed Vc: m/min) (1) f for Grooving (mm/rev) Workpiece Cermet MEGACOAT PVD Coated Carbide Carbide (2) f for Turning (mm/rev) Material TN6020 PR1225 PR1025 KW10 (3) ap for Turning (mm) Remarks GE& 100~200-010A GE& 100~200-010B GE& 250~300-020B 100~200-100AR 100~200-100BR ☆ ★ ☆ (1) 0.01~0.03 (1) 0.02~0.04 (1) 0.02~0.04 Carbon Steel 50~80 50~80 50~80 - (2) 0.01~0.03 (2) 0.02~0.04 (2) 0.02~0.04 (3) Max. 0.05 (3) Max. 0.05 (3) Max. 0.1 ☆ ★ ☆ (1) 0.01~0.03 (1) 0.02~0.04 (1) 0.02~0.04 Alloy Steel 50~80 50~80 50~80 - (2) 0.01~0.03 (2) 0.02~0.04 (2) 0.02~0.04 (3) Max. 0.05 (3) Max. 0.05 (3) Max. 0.1 ★ ☆ (1) 0.01~0.03 (1) 0.01~0.03 (1) 0.01~0.03 Stainless Steel - 50~80 50~80 - (2) 0.01~0.03 (2) 0.01~0.03 (2) 0.01~0.03 (3) Max. 0.05 (3) Max. 0.05 (3) Max. 0.1 Coolant ★ (1) 0.01~0.03 (1) 0.02~0.04 (1) 0.02~0.04 Cast Iron - - - 50~80 (2) 0.01~0.03 (2) 0.02~0.04 (2) 0.02~0.04 (3) Max. 0.05 (3) Max. 0.05 (3) Max. 0.1 ★ (1) 0.01~0.03 (1) 0.02~0.04 (1) 0.02~0.04 Aluminum - - - 50~100 (2) 0.01~0.03 (2) 0.02~0.04 (2) 0.02~0.04 (3) Max. 0.1 (3) Max. 0.1 (3) Max. 0.2 G ★ (1) 0.01~0.03 (1) 0.02~0.04 (1) 0.02~0.04 Brass - - - 50~100 (2) 0.01~0.03 (2) 0.02~0.04 (2) 0.02~0.04 (3) Max. 0.1 (3) Max. 0.1 (3) Max. 0.2 * Use PVD coated grade or carbide for turning with edge width 1mm. (GE&100-005A / 100-005B) ★: 1st Recommendation ☆: 2nd Recommendation Grooving Recommended Cutting Conditions (Ground Chipbreaker: GE&···C(R), GE&···D(R), GE&···E) Recommended Insert Grades (Cutting Speed Vc: m/min) (1) f for Grooving (mm/rev) Cermet MEGACOAT PVD Coated Carbide (2) f for Turning (mm/rev) Carbide (3) ap for Turning (mm) Remarks Workpiece GE& 100~200-010C GE& 250~350-020C Material TN6020 PR1225 PR1025 GW15 200-100CR 250~300-150CR External GE& 100~145-010D GE& 150~195-010D GE& 200~280-020D GE& 300~400-020D 200-100DR 300-150DR GE& 100-010E GE& 150~195-010E GE& 200~225-010E GE& 250~330-020E GE& 350~430-020E GE& 450~500-020E Internal 230-020E ☆ ★ ☆ (1) 0.03~0.08 (1) 0.03~0.08 (1) 0.04~0.09 (1) 0.04~0.09 (1) 0.05~0.12 (1) 0.05~0.12 (1) 0.05~0.12 Face Carbon Steel 120~180 60~140 60~140 - (2) 0.03~0.08 (2) 0.03~0.08 (2) 0.04~0.09 (2) 0.04~0.09 (2) 0.05~0.1 (2) 0.05~0.1 (2) 0.05~0.1 (3) Max. 0.3 (3) Max. 0.3 (3) Max. 0.3 (3) Max. 0.3 (3) Max. 0.5 (3) Max. 0.5 (3) Max. 0.5 ☆ ★ ☆ (1) 0.03~0.07 (1) 0.03~0.07 (1) 0.04~0.08 (1) 0.04~0.08 (1) 0.05~0.1 (1) 0.05~0.1 (1) 0.05~0.1 Alloy Steel 100~160 60~120 60~120 - (2) 0.03~0.1 (2) 0.03~0.1 (2) 0.04~0.08 (2) 0.04~0.08 (2) 0.05~0.1 (2) 0.05~0.1 (2) 0.05~0.1 (3) Max. 0.3 (3) Max. 0.3 (3) Max. 0.3 (3) Max. 0.3 (3) Max. 0.5 (3) Max. 0.5 (3) Max. 0.5 ☆ ★ ☆ (1) 0.03~0.07 (1) 0.03~0.07 (1) 0.04~0.08 (1) 0.04~0.08 (1) 0.05~0.1 (1) 0.05~0.1 (1) 0.05~0.1 Stainless Steel 70~130 60~110 60~110 - (2) 0.03~0.1 (2) 0.03~0.1 (2) 0.04~0.08 (2) 0.04~0.08 (2) 0.05~0.1 (2) 0.05~0.1 (2) 0.05~0.1 Coolant (3) Max. 0.3 (3) Max. 0.3 (3) Max. 0.3 (3) Max. 0.3 (3) Max. 0.5 (3) Max. 0.5 (3) Max. 0.5 ★ (1) 0.03~0.08 (1) 0.03~0.08 (1) 0.04~0.09 (1) 0.04~0.09 (1) 0.05~0.12 (1) 0.05~0.12 (1) 0.05~0.12 Cast Iron - - - 60~100 (2) 0.03~0.08 (2) 0.03~0.08 (2) 0.04~0.09 (2) 0.04~0.09 (2) 0.05~0.1 (2) 0.05~0.1 (2) 0.05~0.1 (3) Max. 0.3 (3) Max. 0.3 (3) Max. 0.3 (3) Max. 0.3 (3) Max. 0.5 (3) Max. 0.5 (3) Max. 0.5 ★ (1) 0.05~0.12 (1) 0.05~0.12 (1) 0.05~0.15 (1) 0.05~0.15 (1) 0.08~0.15 (1) 0.08~0.15 (1) 0.08~0.15 Aluminum - - - 150~300 (2) 0.05~0.12 (2) 0.05~0.12 (2) 0.05~0.15 (2) 0.05~0.15 (2) 0.08~0.15 (2) 0.08~0.15 (2) 0.08~0.15 (3) Max. 0.5 (3) Max. 0.5 (3) Max. 0.5 (3) Max. 0.5 (3) Max. 0.8 (3) Max. 0.8 (3) Max. 0.8 ★ (1) 0.05~0.12 (1) 0.05~0.12 (1) 0.05~0.15 (1) 0.05~0.15 (1) 0.08~0.15 (1) 0.08~0.15 (1) 0.08~0.15 Brass - - - 100~250 (2) 0.05~0.12 (2) 0.05~0.12 (2) 0.05~0.15 (2) 0.05~0.15 (2) 0.08~0.15 (2) 0.08~0.15 (2) 0.08~0.15 (3) Max. 0.5 (3) Max. 0.5 (3) Max. 0.5 (3) Max. 0.5 (3) Max. 0.8 (3) Max. 0.8 (3) Max. 0.8 * Use PVD coated grade or carbide for turning with edge width 1mm. (GE&100-010C / 100-010D / 100-010E) ★: 1st Recommendation ☆: 2nd Recommendation Recommended Cutting Conditions (Molded Chipbreakers: GER···CM, GER···DM, GER···EM) Recommended Insert Grades (Cutting Speed Vc: m/min) (1) f for Grooving (mm/rev) Cermet MEGACOAT PVD Coated Carbide (2) f for Turning (mm/rev) Workpiece Carbide Material TN6020 PR1225 PR1025 GW15 (3) ap for Turning (mm) Remarks GER 150~200-010CM GER 250~350-020CM GER 150~200-010DM GER 230~250-020DM GER 300~400-020DM GER 150~200-010EM GER 250~300-020EM GER 350~400-020EM GER 450~500-020EM ★ ☆ (1) 0.03~0.1 (1) 0.03~0.12 (1) 0.04~0.12 (1) 0.05~0.12 (1) 0.05~0.12 (1) 0.05~0.12 Carbon Steel - 60~160 60~160 - (2) 0.03~0.1 (2) 0.03~0.1 (2) 0.04~0.1 (2) 0.05~0.1 (2) 0.05~0.1 (2) 0.05~0.1 (3) Max.1.0 (3) Max.1.5 (3) Max.1.5 (3) Max.1.5 (3) Max.1.5 (3) Max.1.5 ★ ☆ (1) 0.03~0.1 (1) 0.03~0.1 (1) 0.04~0.12 (1) 0.05~0.12 (1) 0.05~0.12 (1) 0.05~0.12 Alloy Steel - 60~140 60~140 - (2) 0.03~0.1 (2) 0.03~0.1 (2) 0.04~0.1 (2) 0.05~0.1 (2) 0.05~0.1 (2) 0.05~0.1 Coolant (3) Max.1.0 (3) Max.1.5 (3) Max.1.5 (3) Max.1.5 (3) Max.1.5 (3) Max.1.5 ★ ☆ (1) 0.03~0.08 (1) 0.03~0.08 (1) 0.04~0.08 (1) 0.05~0.1 (1) 0.05~0.1 (1) 0.05~0.1 Stainless Steel - 60~110 60~110 - (2) 0.03~0.1 (2) 0.03~0.1 (2) 0.04~0.1 (2) 0.05~0.1 (2) 0.05~0.1 (2) 0.05~0.1 (3) Max.1.0 (3) Max.1.5 (3) Max.1.5 (3) Max.1.5 (3) Max.1.5 (3) Max.1.5 ★: 1st Recommendation ☆: 2nd Recommendation G52