Основной каталог Kyocera 2016-2017 - страница 376

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

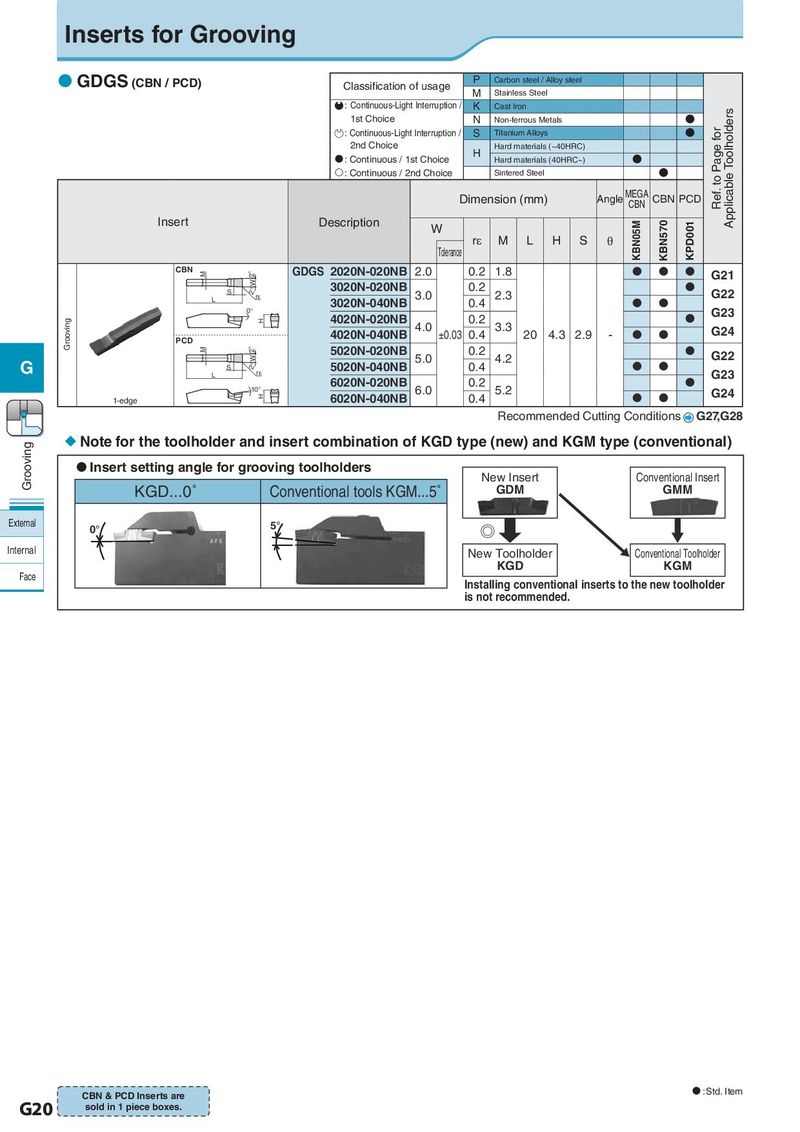

Inserts for Grooving GDGS (CBN / PCD) Classification of usage P Carbon steel / Alloy steel M Stainless Steel : Continuous-Light Interruption / K Cast Iron Applicable Toolholders 1st Choice N Non-ferrous Metals : Continuous-Light Interruption / S Titanium Alloys Ref. to Page for 2nd Choice H Hard materials (~40HRC) : Continuous / 1st Choice Hard materials (40HRC~) : Continuous / 2nd Choice Sintered Steel Dimension (mm) Angle MEGA CBN PCD CBN Insert Description W KBN05M KBN570 KPD001 rε M L H S θ Tolerance CBN M 2° GDGS 2020N-020NB 2.0 0.2 1.8 G21 W 3020N-020NB 0.2 S 2° rε 3.0 2.3 G22 L 3020N-040NB 0.4 0° G23 Grooving H 4020N-020NB 4.0 0.2 3.3 4020N-040NB ±0.03 0.4 20 4.3 2.9 - G24 PCD M 2° 5020N-020NB 0.2 G22 W 5.0 4.2 G S 2° 5020N-040NB 0.4 L rε G23 10° 6020N-020NB 6.0 0.2 5.2 G24 1-edge H 6020N-040NB 0.4 Recommended Cutting Conditions G27,G28 Grooving Note for the toolholder and insert combination of KGD type (new) and KGM type (conventional) ● 溝Ins入eれrt ホseルttiダngのaチnッglプe f取or付gけro角oving toolholders New Insert Conventional Insert KGD...0˚ Conventional tools KGM...5˚ GDM GMM External 0° 5° ◎ Internal New Toolholder Conventional Toolholder KGD KGM Face Installing conventional inserts to the new toolholder is not recommended. CBN & PCD Inserts are : Std. Item G20 sold in 1 piece boxes.