Основной каталог Kyocera 2016-2017 - страница 36

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

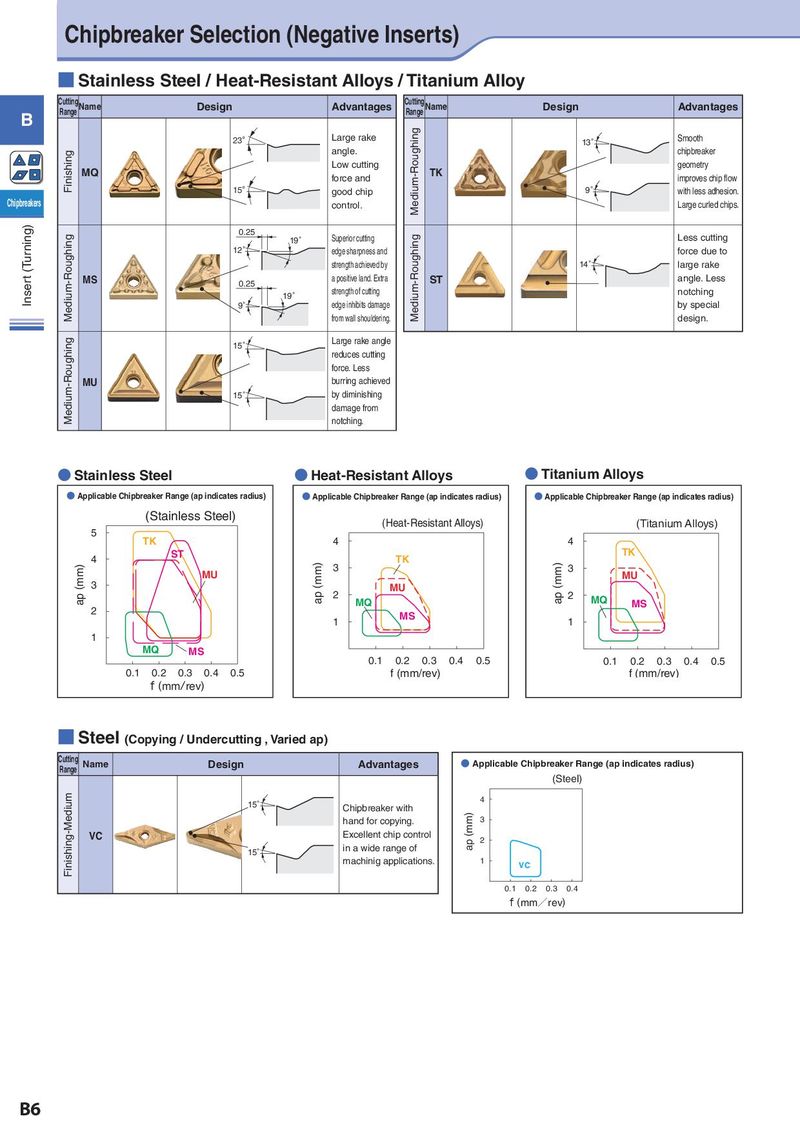

Chipbreaker Selection (Negative Inserts) ■ Stainless Steel / Heat-Resistant Alloys / Titanium Alloy CRuatntigneg Name Design Advantages CRuatntigneg Name Design Advantages B Medium-Roughing 23° Large rake 13° Smooth Finishing angle. chipbreaker MQ Low cutting TK geometry force and improves chip flow 15° good chip 9° with less adhesion. Chipbreakers control. Large curled chips. Insert (Turning) Medium-Roughing 0.25 Superior cutting Medium-Roughing Less cutting 19° 12° edge sharpness and force due to strength achieved by 14° large rake MS 0.25 a positive land. Extra ST angle. Less 19° strength of cutting notching 9° edge inhibits damage by special from wall shouldering. design. Medium-Roughing 15° Large rake angle reduces cutting force. Less MU burring achieved 15° by diminishing damage from notching. ● Stainless Steel ● Heat-Resistant Alloys ● Titanium Alloys ● Applicable Chipbreaker Range (ap indicates radius) ● Applicable Chipbreaker Range (ap indicates radius) ● Applicable Chipbreaker Range (ap indicates radius) (Stainless Steel) (H(eHaet-aRt-eRseisstaisntat nAtllAoyllso)ys) (T(itTaintaiunmiumAllAolylosy) s) 5 TK 4 4 4 4 4 ST TKTK TKTK ap (mm) MU ap (mm)ap (mm)3 3 ap (mm)ap (mm)3 3 MUMU 3 MUMU 2 2 MQMQ 2 2 MQMQ MSMS 2 MSMS 1 1 1 1 1 MQ MS 0.10.1 0.20.2 0.30.3 0.40.4 0.50.5 0.10.1 0.20.2 0.30.3 0.40.4 0.50.5 0.1 0.2 0.3 0.4 0.5 f (mf (m/mre/vre)v) f (mf (m/mre/vre)v) f (mm/rev) ■■耐耐熱熱合合金金用(用(PRP1R31シ3リシリーーズズ)) ■■チチタタンン合合金金用(用(SWSWシリシリーーズズ)) ■ Steel (Copying / Undercutting , Varied ap) Cutting Name Design Advantages ● Applicable Chipbreaker Range (ap indicates radius) Range (Steel) Finishing-Medium 15° 4 Chipbreaker with ap (mm) hand for copying. 3 VC Excellent chip control 2 15° in a wide range of machinig applications. 1 VC 0.1 0.2 0.3 0.4 f (mm/rev) B6