Основной каталог Kyocera 2016-2017 - страница 315

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

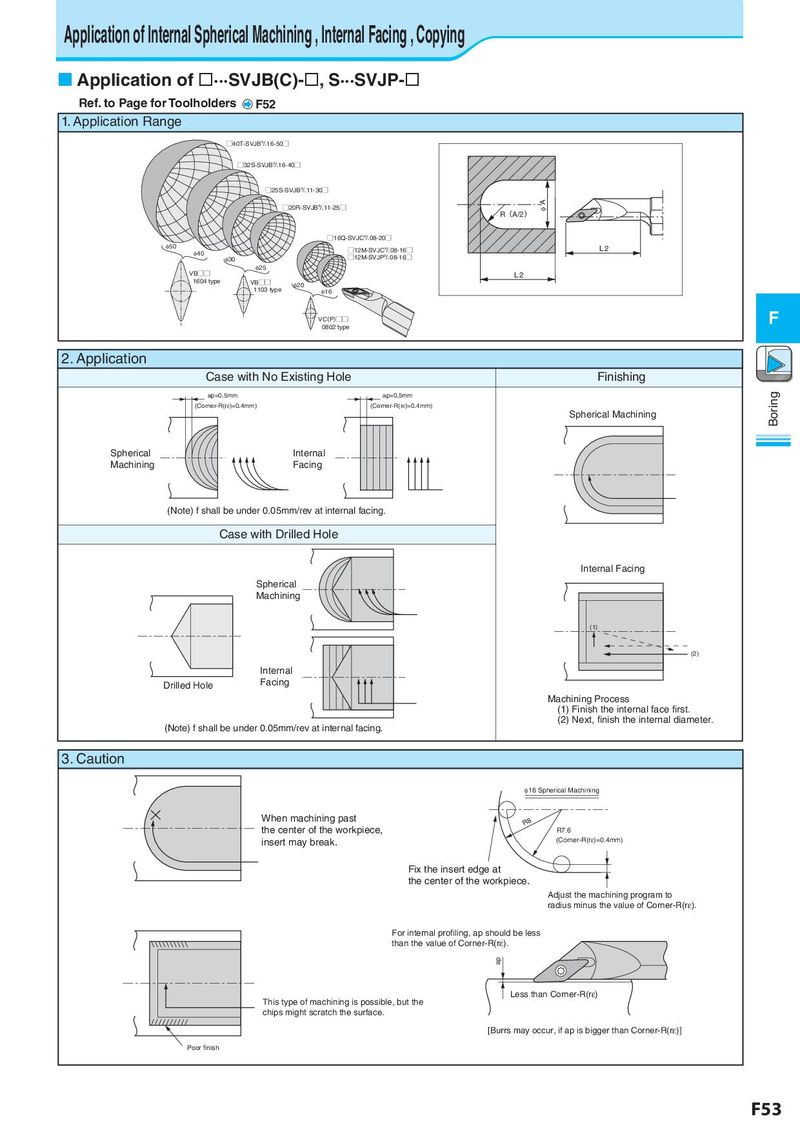

Application of Internal Spherical Machining , Internal Facing , Copying Application of ···SVJB(C)-, S···SVJP- Ref. to Page for Toolholders F52 1. Application Range □40T-SVJB&16-50□ □32S-SVJB&16-40□ □25S-SVJB&11-30□ □20R-SVJB&11-25□ φA R(A/2) □16Q-SVJC&08-20□ φ50 □12M-SVJC&08-16□ L2 φ40 φ30 □12M-SVJP&08-16□ VB□□ φ25 1604 type L2 VB□□ φ20 1103 type φ16 VC(P)□□ F 0802 type 2. Application Case with No Existing Hole Finishing ap=0.5mm ap=0.5mm Boring (Corner-R(rε)=0.4mm) (Corner-R(rε)=0.4mm) Spherical Machining Spherical Internal Machining Facing (Note) f shall be under 0.05mm/rev at internal facing. Case with Drilled Hole Internal Facing Spherical Machining (1) (2) Internal Drilled Hole Facing Machining Process (1) Finish the internal face first. (Note) f shall be under 0.05mm/rev at internal facing. (2) Next, finish the internal diameter. 3. Caution φ16 Spherical Machining When machining past R8 the center of the workpiece, R7.6 insert may break. (Corner-R(rε)=0.4mm) Fix the insert edge at the center of the workpiece. Adjust the machining program to radius minus the value of Corner-R(rε). For internal profiling, ap should be less than the value of Corner-R(rε). ap This type of machining is possible, but the Less than Corner-R(rε) chips might scratch the surface. [Burrs may occur, if ap is bigger than Corner-R(rε)] Poor finish F53