Основной каталог Kyocera 2016-2017 - страница 305

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

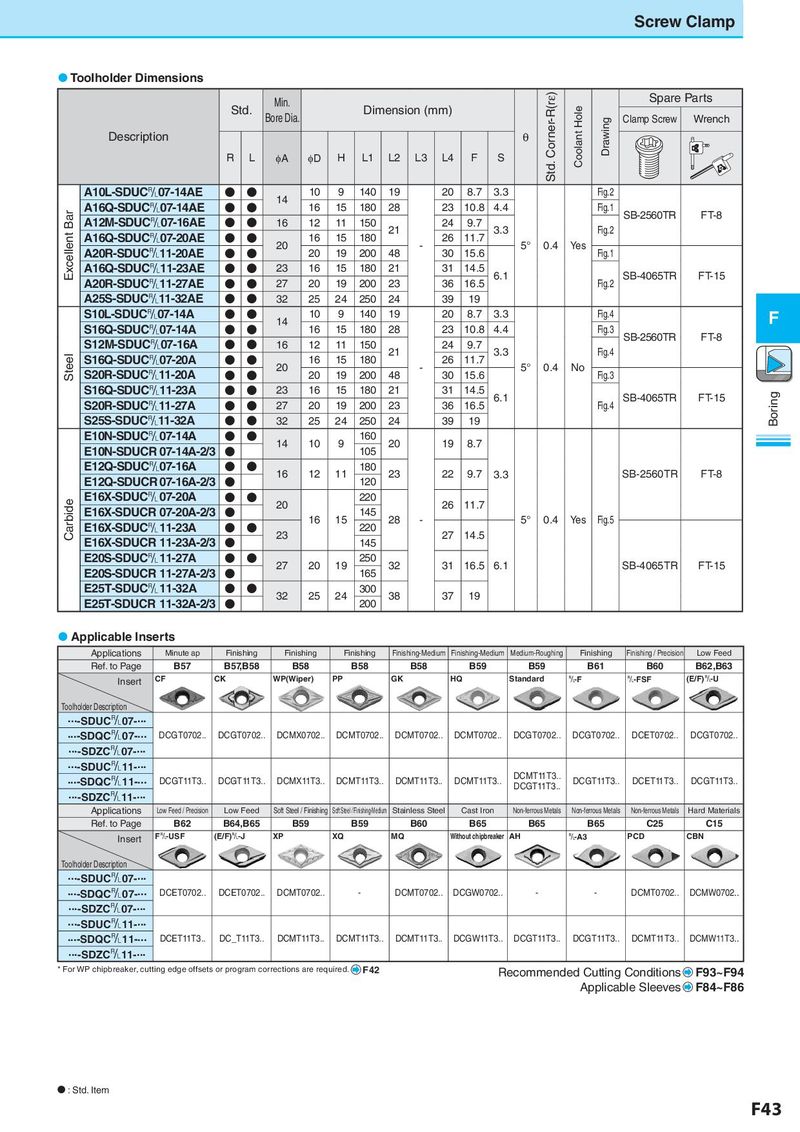

Screw Clamp Toolholder Dimensions Min. Std. Corner-R(rε) Spare Parts Std. Bore Dia. Dimension (mm) Coolant Hole Clamp Screw Wrench Description θ Drawing R L φA φD H L1 L2 L3 L4 F S A10L-SDUC&07-14AE ● ● 14 10 9 140 19 20 8.7 3.3 Fig.2 Excellent Bar A16Q-SDUC&07-14AE ● ● 16 15 180 28 23 10.8 4.4 Fig.1 SB-2560TR FT-8 A12M-SDUC&07-16AE ● ● 16 12 11 150 21 24 9.7 3.3 Fig.2 A16Q-SDUC&07-20AE ● ● 20 16 15 180 - 26 11.7 5° 0.4 Yes A20R-SDUC&11-20AE ● ● 20 19 200 48 30 15.6 Fig.1 A16Q-SDUC&11-23AE ● ● 23 16 15 180 21 31 14.5 6.1 SB-4065TR FT-15 A20R-SDUC&11-27AE ● ● 27 20 19 200 23 36 16.5 Fig.2 A25S-SDUC&11-32AE ● ● 32 25 24 250 24 39 19 S10L-SDUC&07-14A ● ● 14 10 9 140 19 20 8.7 3.3 Fig.4 F S16Q-SDUC&07-14A ● ● 16 15 180 28 23 10.8 4.4 Fig.3 SB-2560TR FT-8 S12M-SDUC&07-16A ● ● 16 12 11 150 21 24 9.7 3.3 Fig.4 Steel S16Q-SDUC&07-20A ● ● 20 16 15 180 - 26 11.7 5° 0.4 No S20R-SDUC&11-20A ● ● 20 19 200 48 30 15.6 Fig.3 S16Q-SDUC&11-23A ● ● 23 16 15 180 21 31 14.5 6.1 SB-4065TR FT-15 Boring S20R-SDUC&11-27A ● ● 27 20 19 200 23 36 16.5 Fig.4 S25S-SDUC&11-32A ● ● 32 25 24 250 24 39 19 E10N-SDUC& 07-14A ● ● 14 10 9 160 20 19 8.7 E10N-SDUCR 07-14A-2/3 ● 105 E12Q-SDUC& 07-16A ● ● 16 12 11 180 23 22 9.7 3.3 SB-2560TR FT-8 E12Q-SDUCR 07-16A-2/3 ● 120 Carbide E16X-SDUC& 07-20A ● ● 20 220 26 11.7 E16X-SDUCR 07-20A-2/3 ● 16 15 145 28 - 5° 0.4 Yes Fig.5 E16X-SDUC& 11-23A ● ● 23 220 27 14.5 E16X-SDUCR 11-23A-2/3 ● 145 E20S-SDUC& 11-27A ● ● 27 20 19 250 32 31 16.5 6.1 SB-4065TR FT-15 E20S-SDUCR 11-27A-2/3 ● 165 E25T-SDUC& 11-32A ● ● 32 25 24 300 38 37 19 E25T-SDUCR 11-32A-2/3 ● 200 Applicable Inserts Applications Minute ap Finishing Finishing Finishing Finishing-Medium Finishing-Medium Medium-Roughing Finishing Finishing / Precision Low Feed Ref. to Page B57 B57,B58 B58 B58 B58 B59 B59 B61 B60 B62,B63 Insert CF CK WP(Wiper) PP GK HQ Standard &-F &-FSF (E/F)&-U Toolholder Description ...-SDUC&07-... ...-SDQC&07-... DCGT0702.. DCGT0702.. DCMX0702.. DCMT0702.. DCMT0702.. DCMT0702.. DCGT0702.. DCGT0702.. DCET0702.. DCGT0702.. ...-SDZC&07-... ...-SDUC&11-... DCMT11T3.. ...-SDQC&11-... DCGT11T3.. DCGT11T3.. DCMX11T3.. DCMT11T3.. DCMT11T3.. DCMT11T3.. DCGT11T3.. DCGT11T3.. DCET11T3.. DCGT11T3.. ...-SDZC&11-... Applications Low Feed / Precision Low Feed Soft Steel / Finishing Soft Steel / Finishing-Medium Stainless Steel Cast Iron Non-ferrous Metals Non-ferrous Metals Non-ferrous Metals Hard Materials Ref. to Page B62 B64,B65 B59 B59 B60 B65 B65 B65 C25 C15 Insert F&-USF (E/F)&-J XP XQ MQ Without chipbreaker AH &-A3 PCD CBN Toolholder Description ...-SDUC&07-... ...-SDQC&07-... DCET0702.. DCET0702.. DCMT0702.. - DCMT0702.. DCGW0702.. - - DCMT0702.. DCMW0702.. ...-SDZC&07-... ...-SDUC&11-... ...-SDQC&11-... DCET11T3.. DC_T11T3.. DCMT11T3.. DCMT11T3.. DCMT11T3.. DCGW11T3.. DCGT11T3.. DCGT11T3.. DCMT11T3.. DCMW11T3.. ...-SDZC&11-... * For WP chipbreaker, cutting edge offsets or program corrections are required. F42 Recommended Cutting Conditions F93~F94 Applicable Sleeves F84~F86 N : Std. Item F43