Основной каталог Kyocera 2016-2017 - страница 297

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

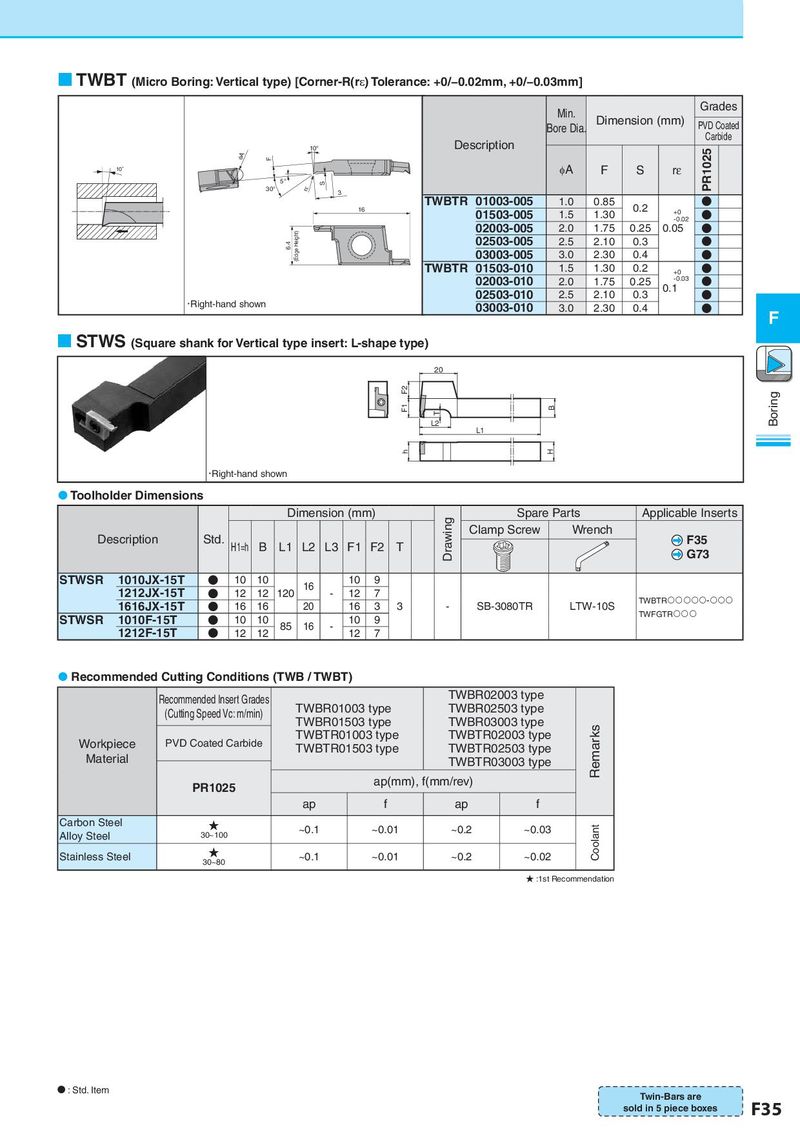

TWBT (Micro Boring: Vertical type) [Corner-R(rε) Tolerance: +0/−0.02mm, +0/−0.03mm] Min. Grades Bore Dia. Dimension (mm) PVD Coated Description Carbide 10° PR1025 φA F 10° φA F S rε 5° S 30° rε 3 TWBTR 01003-005 1.0 0.85 0.2 ● 16 01503-005 1.5 1.30 +0 ● -0.02 (Edge Height) 02003-005 2.0 1.75 0.25 0.05 ● 6.4 02503-005 2.5 2.10 0.3 ● 03003-005 3.0 2.30 0.4 ● TWBTR 01503-010 1.5 1.30 0.2 +0 ● 02003-010 2.0 1.75 0.25 -0.03 ● 02503-010 2.5 2.10 0.3 0.1 ● • Right-hand shown 03003-010 3.0 2.30 0.4 ● F STWS (Square shank for Vertical type insert: L-shape type) 20 F2 Boring F1 B T L2 L1 h H • Right-hand shown Toolholder Dimensions Dimension (mm) Drawing Spare Parts Applicable Inserts Description Std. Clamp Screw Wrench F35 H1=h B L1 L2 L3 F1 F2 T G73 STWSR 1010JX-15T ● 10 10 16 10 9 1212JX-15T ● 12 12 120 - 12 7 TWBTR- 1616JX-15T ● 16 16 20 16 3 3 - SB-3080TR LTW-10S TWFGTR STWSR 1010F-15T ● 10 10 85 16 - 10 9 1212F-15T ● 12 12 12 7 Recommended Cutting Conditions (TWB / TWBT) Recommended Insert Grades TWBR02003 type (Cutting Speed Vc: m/min) TWBR01003 type TWBR02503 type TWBR01503 type TWBR03003 type Remarks Workpiece PVD Coated Carbide TWBTR01003 type TWBTR02003 type Material TWBTR01503 type TWBTR02503 type TWBTR03003 type PR1025 ap(mm), f(mm/rev) ap f ap f Carbon Steel ★ ~0.1 ~0.01 ~0.2 ~0.03 Coolant Alloy Steel 30~100 Stainless Steel ★ ~0.1 ~0.01 ~0.2 ~0.02 30~80 ★ :1st Recommendation N : Std. Item Twin-Bars are sold in 5 piece boxes F35