Основной каталог Kyocera 2016-2017 - страница 264

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

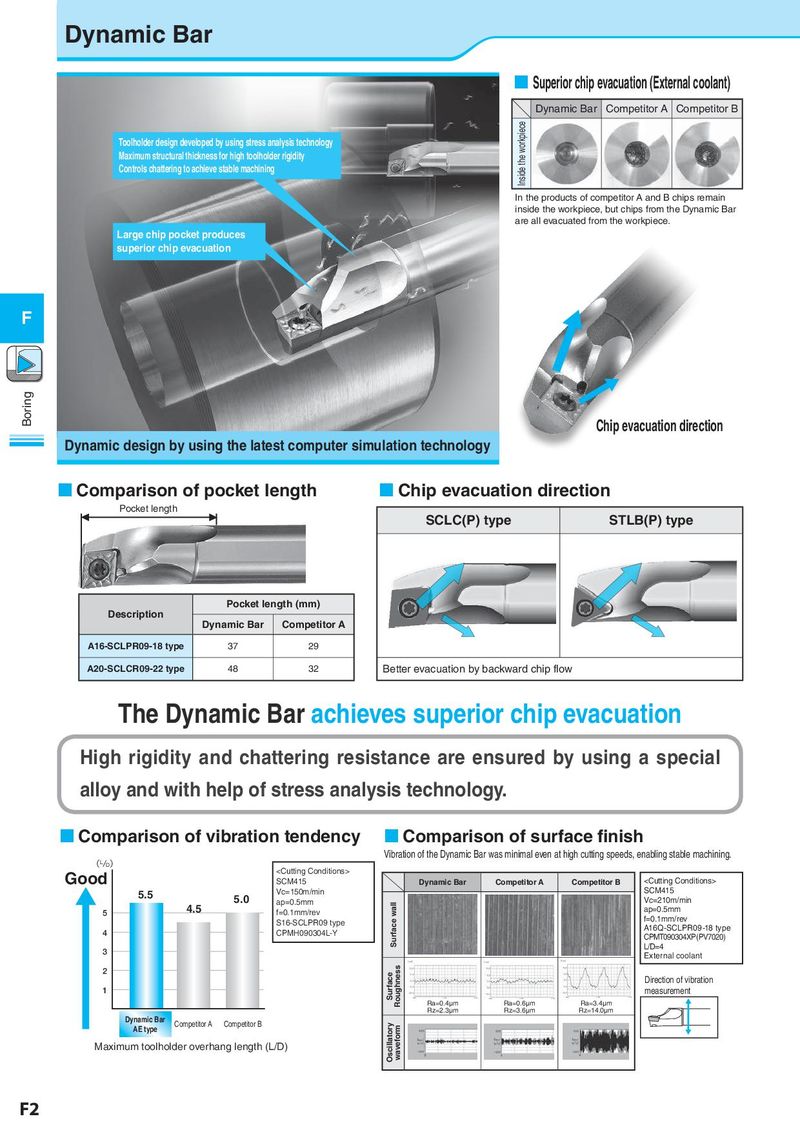

Dynamic Bar

Superior chip evacuation (External coolant)

Dynamic Bar Competitor A Competitor B

Toolholder design developed by using stress analysis technology Inside the workpiece

Maximum structural thickness for high toolholder rigidity

Controls chattering to achieve stable machining

In the products of competitor A and B chips remain

inside the workpiece, but chips from the Dynamic Bar

are all evacuated from the workpiece.

Large chip pocket produces

superior chip evacuation

F

Boring Chip evacuation direction

Dynamic design by using the latest computer simulation technology

Comparison of pocket length Chip evacuation direction

Pocket length

SCLC(P) type STLB(P) type

Pocket length (mm)

Description

Dynamic Bar Competitor A

A16-SCLPR09-18 type 37 29

A20-SCLCR09-22 type 48 32 Better evacuation by backward chip flow

The Dynamic Bar achieves superior chip evacuation

High rigidity and chattering resistance are ensured by using a special

alloy and with help of stress analysis technology.

Comparison of vibration tendency Comparison of surface finish

Vibration of the Dynamic Bar was minimal even at high cutting speeds, enabling stable machining.

(L/D)

Good