Основной каталог Kyocera 2016-2017 - страница 222

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

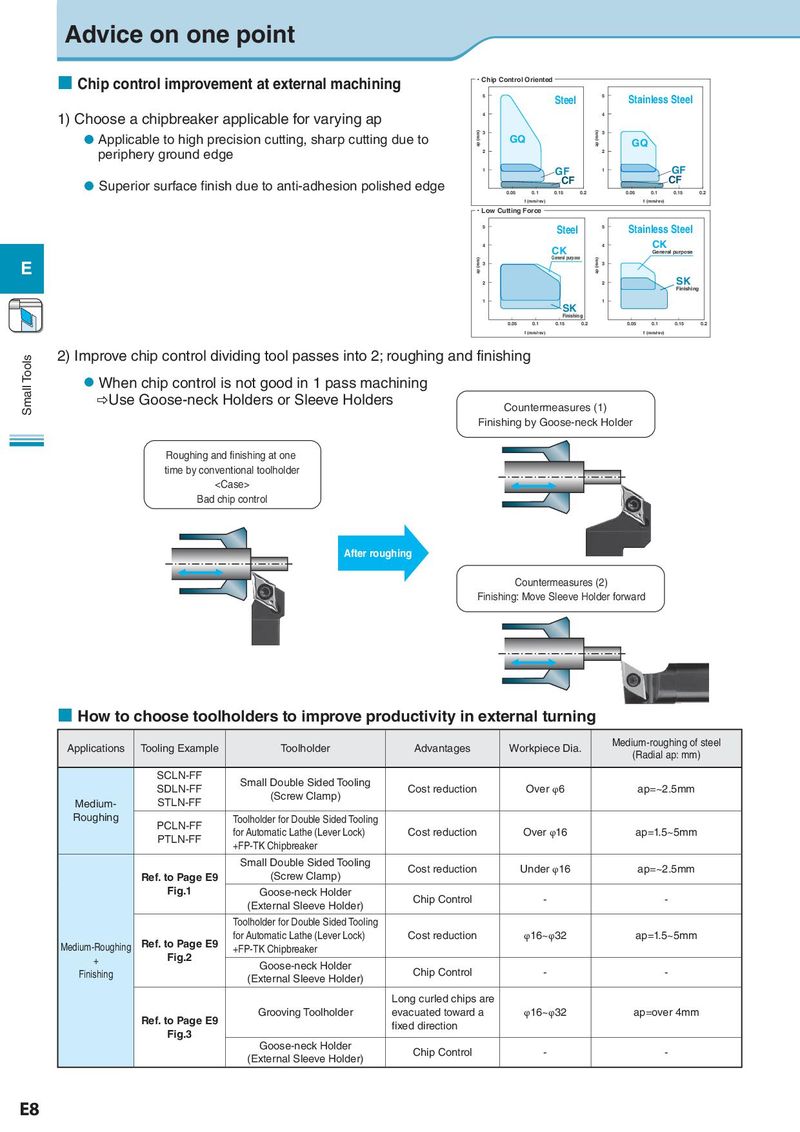

Advice on one point

¢ Chip control improvement at external machining ・Chip Control Oriented

5 Steel 5 Stainless Steel

1) Choose a chipbreaker applicable for varying ap 4 4

l Applicable to high precision cutting, sharp cutting due to (mm) 3 GQ (mm) 3

ap ap GQ

periphery ground edge 2 2

1 GF 1 GF

l Superior surface finish due to anti-adhesion polished edge CF CF

0.05 0.1 0.15 0.2 0.05 0.1 0.15 0.2

f (mm/rev) f (mm/rev)

・Low Cutting Force

5 Steel 5 Stainless Steel

4 CK 4 CK

General purpose

ap (mm) General purpose ap (mm)

E 3 3

2 2 SK

Finishing

1 1

SK

Finishing

0.05 0.1 0.15 0.2 0.05 0.1 0.15 0.2

f (mm/rev) f (mm/rev)

Small Tools 2) Improve chip control dividing tool passes into 2; roughing and finishing

l When chip control is not good in 1 pass machining

_Use Goose-neck Holders or Sleeve Holders Countermeasures (1)

Finishing by Goose-neck Holder

Roughing and finishing at one

time by conventional toolholder