Основной каталог Kyocera 2016-2017 - страница 19

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

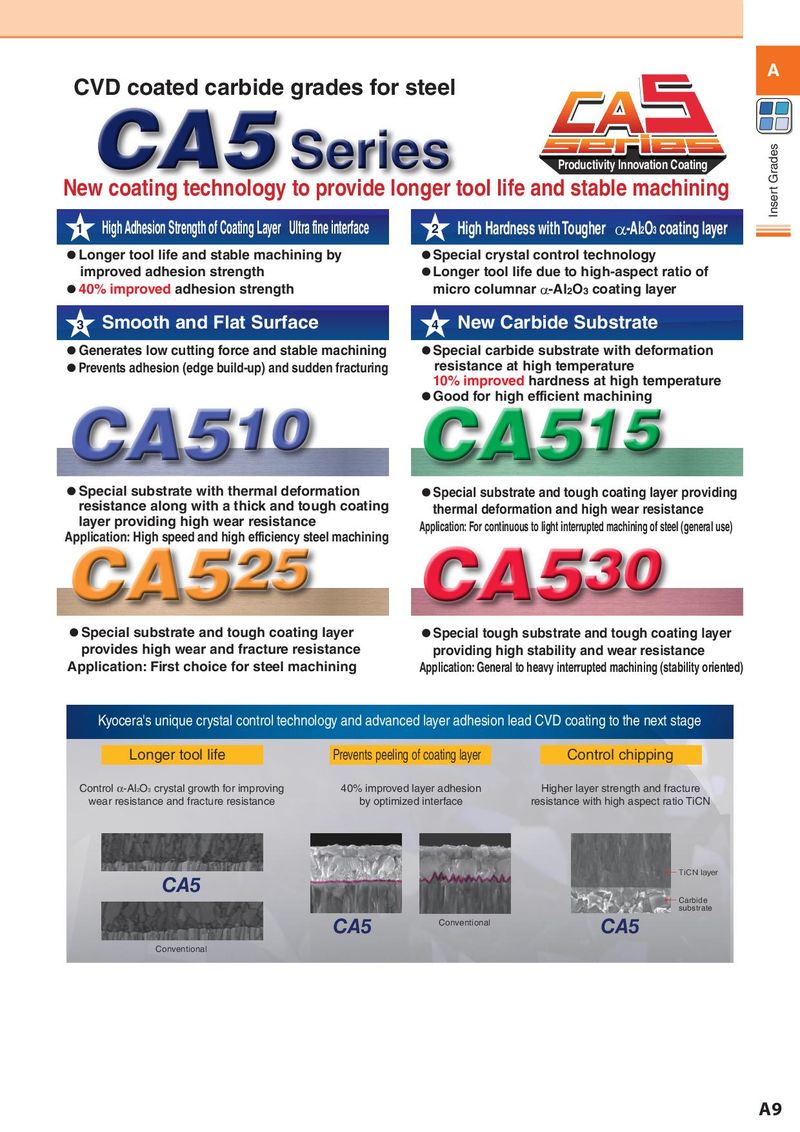

CVD coated carbide grades for steel A CA5 Series Productivity Innovation Coating Insert Grades New coating technology to provide longer tool life and stable machining ★1 High Adhesion Strength of Coating Layer Ultra fine interface ★2 High Hardness with Tougher α-Al2O3 coating layer ◦Longer tool life and stable machining by ◦Special crystal control technology improved adhesion strength ◦Longer tool life due to high-aspect ratio of ◦40% improved adhesion strength micro columnar α-Al2O3 coating layer ★3 Smooth and Flat Surface ★4 New Carbide Substrate ◦Generates low cutting force and stable machining ◦Special carbide substrate with deformation ◦Prevents adhesion (edge build-up) and sudden fracturing resistance at high temperature 10% improved hardness at high temperature ◦Good for high efficient machining CA510 CA515 ◦Special substrate with thermal deformation ◦Special substrate and tough coating layer providing resistance along with a thick and tough coating thermal deformation and high wear resistance layer providing high wear resistance Application: For continuous to light interrupted machining of steel (general use) Application: High speed and high efficiency steel machining CA525 CA530 ◦Special substrate and tough coating layer ◦Special tough substrate and tough coating layer provides high wear and fracture resistance providing high stability and wear resistance Application: First choice先fo進r sCteVelDmコacーhinテinィg ング Applicationが: Ge常nera識l toをhea変vy iえnterるrupted machining (stability oriented) Kyocera's unique crystal control technology and advanced layer adhesion lead CVD coating to the next stage Longer tool life Prevents peeling of coating layer Control chipping Control α-Al2O3 crystal growth for improving 40% improved layer adhesion Higher layer strength and fracture wear resistance and fracture resistance by optimized interface resistance with high aspect ratio TiCN TiCN layer CA5 Carbide substrate CA5 Conventional CA5 Conventional A9