Основной каталог Kyocera 2016-2017 - страница 17

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

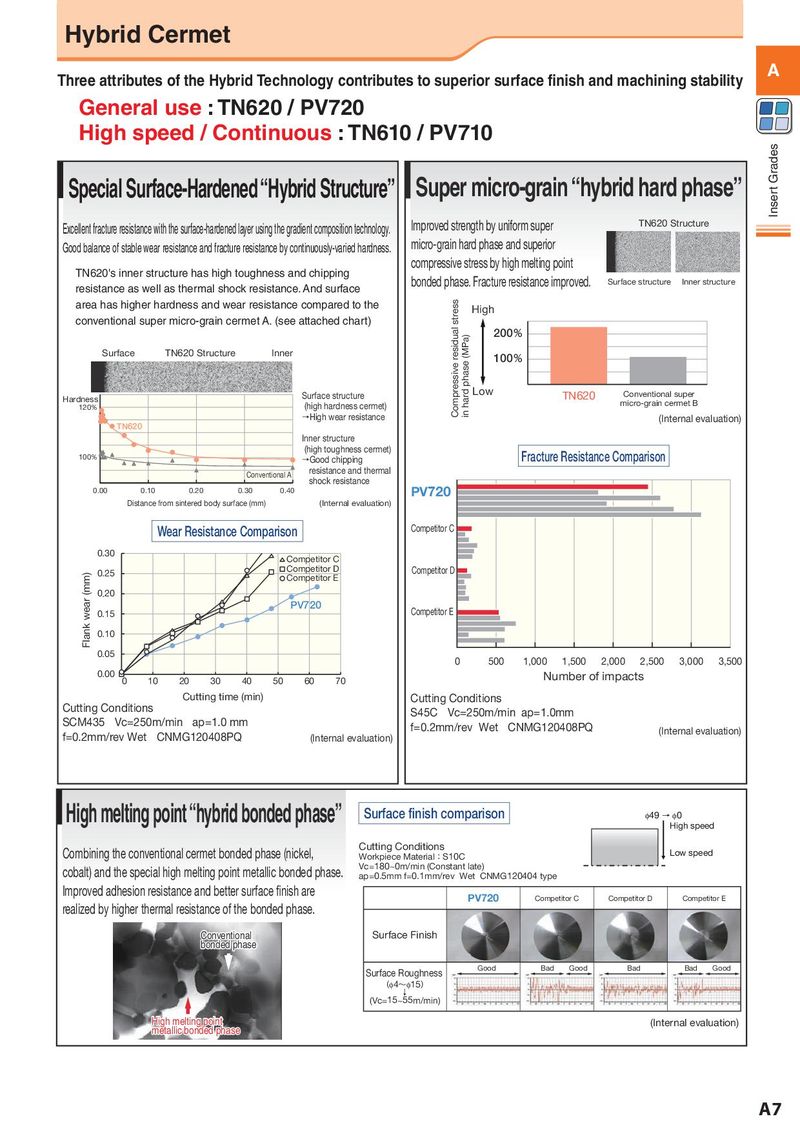

Hybrid Cermet Three attributes of the Hybrid Technology contributes to superior surface finish and machining stability A General use : TN620 / PV720 High speed / Continuous : TN610 / PV710 Insert Grades Special Surface-Hardened “Hybrid Structure” Super micro-grain “hybrid hard phase” Excellent fracture resistance with the surface-hardened layer using the gradient composition technology. Improved strength by uniform super TN620 Structure Good balance of stable wear resistance and fracture resistance by continuously-varied hardness. micro-grain hard phase and superior TN620's inner structure has high toughness and chipping compressive stress by high melting point resistance as well as thermal shock resistance. And surface bonded phase. Fracture resistance improved. Surface structure Inner structure area has higher hardness and wear resistance compared to the Compressive residual stress High conventional super micro-grain cermet A. (see attached chart) in hard phase (MPa) 200% Surface TN620 Structure Inner 100% Hardness Surface structure Low TN620 Conventional super 120% (high hardness cermet) micro-grain cermet B →High wear resistance (Internal evaluation) TN620 Inner structure (high toughness cermet) Fracture Resistance Comparison 100% →Good chipping Conventional A resistance and thermal shock resistance 0.00 0.10 0.20 0.30 0.40 PV720 Distance from sintered body surface (mm) (Internal evaluation) Wear Resistance Comparison Competitor C 0.30 Competitor C Flank wear (mm) 0.25 Competitor D Competitor D Competitor E 0.20 0.15 PV720 Competitor E 0.10 0.05 0 500 1,000 1,500 2,000 2,500 3,000 3,500 0.00 0 10 20 30 40 50 60 70 Number of impacts Cutting time (min) Cutting Conditions Cutting Conditions S45C Vc=250m/min ap=1.0mm SCM435 Vc=250m/min ap=1.0 mm f=0.2mm/rev Wet CNMG120408PQ (Internal evaluation) f=0.2mm/rev Wet CNMG120408PQ (Internal evaluation) High melting point “hybrid bonded phase” Surface finish comparison φ49 → φ0 High speed Combining the conventional cermet bonded phase (nickel, Cutting Conditions Low speed Workpiece Material:S10C cobalt) and the special high melting point metallic bonded phase. Vc=180~0m/min (Constant late) ap=0.5mm f=0.1mm/rev Wet CNMG120404 type Improved adhesion resistance and better surface nish are PV720 Competitor C Competitor D Competitor E realized by higher thermal resistance of the bonded phase. Conventional Surface Finish bonded phase Surface Roughness Good Bad Good Bad Bad Good (φ4~φ15) ↓ (Vc=15~55m/min) High melting point (Internal evaluation) metallic bonded phase A7