Основной каталог Kyocera 2016-2017 - страница 16

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

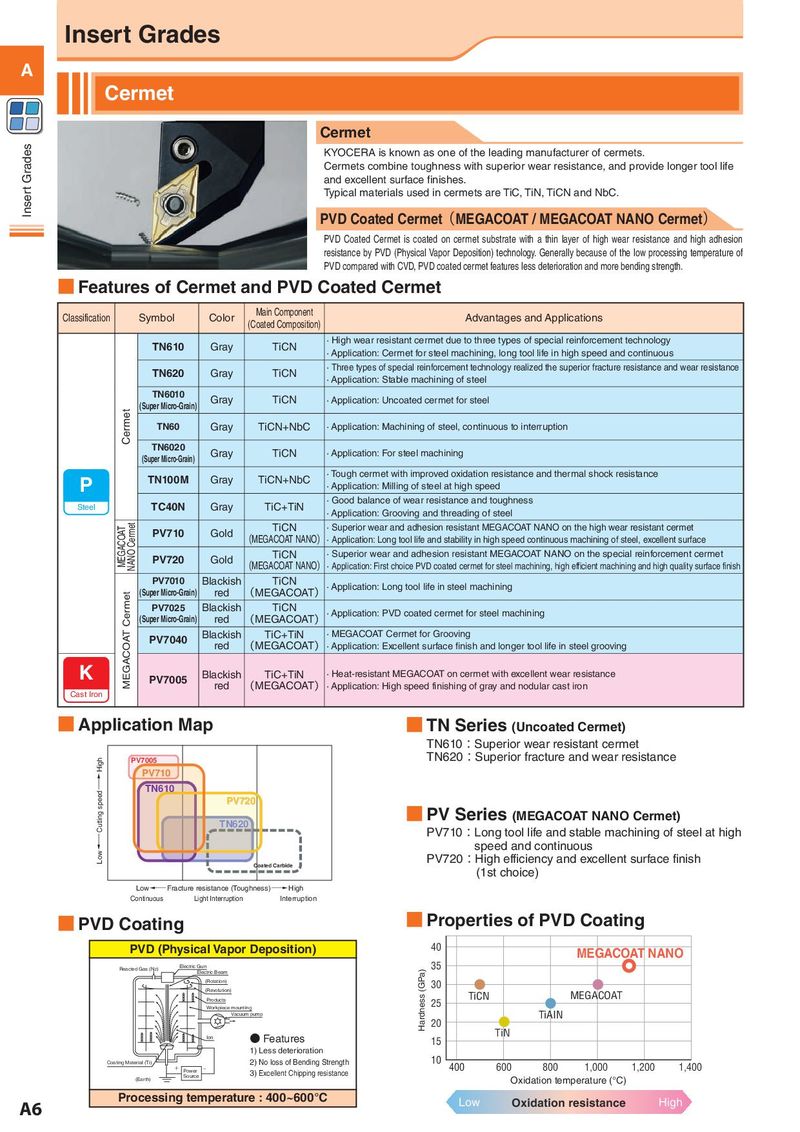

Insert Grades A Cermet Cermet Insert Grades KYOCERA is known as one of the leading manufacturer of cermets. Cermets combine toughness with superior wear resistance, and provide longer tool life and excellent surface finishes. Typical materials used in cermets are TiC, TiN, TiCN and NbC. PVD Coated Cermet(MEGACOAT / MEGACOAT NANO Cermet) PVD Coated Cermet is coated on cermet substrate with a thin layer of high wear resistance and high adhesion resistance by PVD (Physical Vapor Deposition) technology. Generally because of the low processing temperature of PVD compared with CVD, PVD coated cermet features less deterioration and more bending strength. ■ Features of Cermet and PVD Coated Cermet Classification Symbol Color Main Component Advantages and Applications (Coated Composition) TN610 Gray TiCN · High wear resistant cermet due to three types of special reinforcement technology · Application: Cermet for steel machining, long tool life in high speed and continuous TN620 Gray TiCN · Three types of special reinforcement technology realized the superior fracture resistance and wear resistance · Application: Stable machining of steel TN6010 Gray TiCN · Application: Uncoated cermet for steel Cermet (Super Micro-Grain) TN60 Gray TiCN+NbC · Application: Machining of steel, continuous to interruption TN6020 Gray TiCN · Application: For steel machining (Super Micro-Grain) P TN100M Gray TiCN+NbC · Tough cermet with improved oxidation resistance and thermal shock resistance · Application: Milling of steel at high speed Steel TC40N Gray TiC+TiN · Good balance of wear resistance and toughness · Application: Grooving and threading of steel MEGACOATNANO Cermet PV710 Gold TiCN · Superior wear and adhesion resistant MEGACOAT NANO on the high wear resistant cermet (MEGACOAT NANO) · Application: Long tool life and stability in high speed continuous machining of steel, excellent surface PV720 Gold TiCN · Superior wear and adhesion resistant MEGACOAT NANO on the special reinforcement cermet (MEGACOAT NANO) · Application: First choice PVD coated cermet for steel machining, high efficient machining and high quality surface finish PV7010 Blackish TiCN · Application: Long tool life in steel machining MEGACOAT Cermet (Super Micro-Grain) red (MEGACOAT) PV7025 Blackish TiCN · Application: PVD coated cermet for steel machining (Super Micro-Grain) red (MEGACOAT) PV7040 Blackish TiC+TiN · MEGACOAT Cermet for Grooving red (MEGACOAT) · Application: Excellent surface finish and longer tool life in steel grooving K PV7005 Blackish TiC+TiN · Heat-resistant MEGACOAT on cermet with excellent wear resistance red (MEGACOAT) · Application: High speed finishing of gray and nodular cast iron Cast Iron ■ Application Map ■ TN Series (Uncoated Cermet) TN610:Superior wear resistant cermet High PV7005 TN620:Superior fracture and wear resistance PV710 Cutting speed→ TN610 PV720 ■ PV Series (MEGACOAT NANO Cermet) TN620 PV710:Long tool life and stable machining of steel at high Low ← speed and continuous Coated Carbide PV720:High efficiency and excellent surface finish (1st choice) Low←Fracture resistance (Toughness)→High Continuous Light Interruption Interruption ■ PVD Coating ■ Properties of PVD Coating PVD (Physical Vapor Deposition) 40 MEGACOAT NANO Reacted Gas (N2) Electric Gun 35 Electric Beam Hardness (GPa) (Rotation) 30 (Revolution) TiCN MEGACOAT Products 25 Workpiece mounting Vacuum pump TiAIN 20 Ion ● Features 15 TiN 1) Less deterioration Coating Material (Ti) 2) No loss of Bending Strength 10 400 600 800 1,000 1,200 1,400 + Power − 3) Excellent Chipping resistance (Earth) Source Oxidation temperature (°C) A6 Processing temperature : 400~600°C Low Oxidation resistance High