Основной каталог Kyocera 2016-2017 - страница 140

Навигация

Каталог Kyocera фрезы MFH для высокоскоростной обработки

Каталог Kyocera фрезы MFH для высокоскоростной обработки Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы Каталог микроинструмента Kyocera 2015-2016

Каталог микроинструмента Kyocera 2015-2016 Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом

Каталог Kyocera пластины TQ для нарезания резьбы c прессованным стружколомом Каталог Kyocera высокопроизводительные модульные сверла DRA

Каталог Kyocera высокопроизводительные модульные сверла DRA

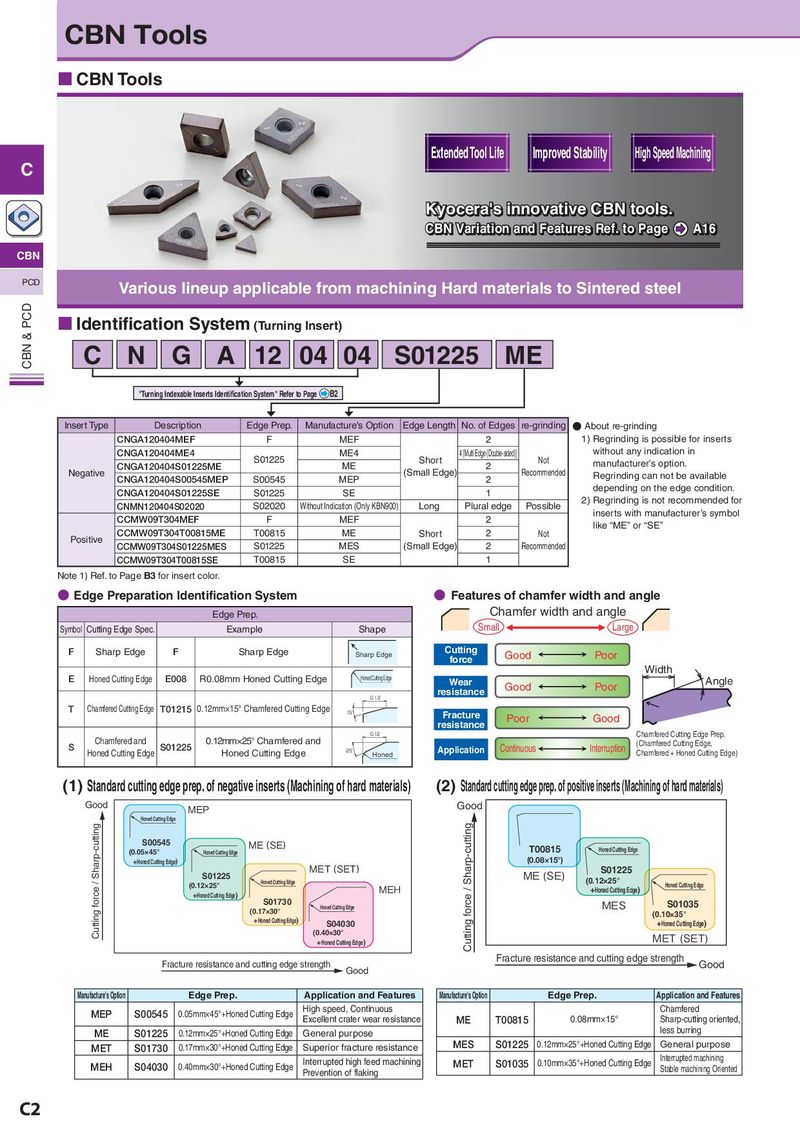

CBN Tools CBN Tools Extended Tool Life Improved Stability High Speed Machining C Kyocera's innovative CBN tools. CBN Variation and Features Ref. to Page A16 CBN PCD Various lineup applicable from machining Hard materials to Sintered steel CBN & PCD Identification System (Turning Insert) C N G A 12 04 04 S01225 ME "Turning Indexable Inserts Identification System" Refer to Page B2 Insert Type Description Edge Prep. Manufacture's Option Edge Length No. of Edges re-grinding ● About re-grinding CNGA120404MEF F MEF 2 1) Regrinding is possible for inserts CNGA120404ME4 ME4 4 [Multi Edge (Double-sided)] without any indication in CNGA120404S01225ME S01225 ME Short 2 Not manufacturer’s option. Negative CNGA120404S00545MEP S00545 MEP (Small Edge) 2 Recommended Regrinding can not be available CNGA120404S01225SE S01225 SE 1 depending on the edge condition. CNMN120404S02020 S02020 Without Indication (Only KBN900) Long Plural edge Possible 2) Regrinding is not recommended for CCMW09T304MEF F MEF 2 inserts with manufacturer’s symbol CCMW09T304T00815ME T00815 ME Short 2 Not like “ME” or “SE” Positive CCMW09T304S01225MES S01225 MES (Small Edge) 2 Recommended CCMW09T304T00815SE T00815 SE 1 Note 1) Ref. to Page B3 for insert color. ● Edge Preparation Identification System ● Features of chamfer width and angle Edge Prep. Chamfer width and angle Symbol Cutting Edge Spec. Example Shape Small Large F Sharp Edge F Sharp Edge Sharp Edge Cutting Good Poor force Width E Honed Cutting Edge E008 R0.08mm Honed Cutting Edge Honed Cutting Edge Wear Angle resistance Good Poor 0.12 T Chamfered Cutting Edge T01215 0.12mm×15° Chamfered Cutting Edge 15° Fracture resistance Poor Good 0.12 Chamfered Cutting Edge Prep. S Chamfered and S01225 0.12mm×25° Chamfered and Continuous Interruption (Chamfered Cutting Edge, Honed Cutting Edge Honed Cutting Edge 25° Honed Application Chamfered + Honed Cutting Edge) (1) Standard cutting edge prep. of negative inserts (Machining of hard materials) (2) Standard cutting edge prep. of positive inserts (Machining of hard materials) Good MEP Good Honed Cutting Edge Cutting force / Sharp-cutting S00545 ME (SE) Cutting force / Sharp-cutting T00815 (0.05×45° Honed Cutting Edge Honed Cutting Edge +Honed Cutting Edge) (0.08×15°) S01225 MET (SET) ME (SE) S01225 (0.12×25° Honed Cutting Edge (0.12×25° Honed Cutting Edge +Honed Cutting Edge) MEH +Honed Cutting Edge) S01730 Honed Cutting Edge MES S01035 (0.17×30° (0.10×35° +Honed Cutting Edge) S04030 +Honed Cutting Edge) (0.40×30° MET (SET) +Honed Cutting Edge) Fracture resistance and cutting edge strength Fracture resistance and cutting edge strength Good Good Manufacture's Option Edge Prep. Application and Features Manufacture's Option Edge Prep. Application and Features MEP S00545 0.05mm×45°+Honed Cutting Edge High speed, Continuous Chamfered Excellent crater wear resistance ME T00815 0.08mm×15° Sharp-cutting oriented, ME S01225 0.12mm×25°+Honed Cutting Edge General purpose less burring MET S01730 0.17mm×30°+Honed Cutting Edge Superior fracture resistance MES S01225 0.12mm×25°+Honed Cutting Edge General purpose Interrupted high feed machining MET S01035 0.10mm×35°+Honed Cutting Edge Interrupted machining MEH S04030 0.40mm×30°+Honed Cutting Edge Prevention of flaking Stable machining Oriented C2