Каталог микроинструмента Kyocera 2015-2016 - страница 87

Навигация

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV

Каталог Kyocera высокоэффективные сверла со сменными пластинами DRV Каталог Kyocera фрезы MRX с позитивными круглыми пластинами

Каталог Kyocera фрезы MRX с позитивными круглыми пластинами Каталог Kyocera фрезы MFK высокоэффективные фрезы для обработки чугуна

Каталог Kyocera фрезы MFK высокоэффективные фрезы для обработки чугуна Каталог Kyocera пластины с CVD покрытием для обработки стали

Каталог Kyocera пластины с CVD покрытием для обработки стали Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

Каталог Kyocera фрезы MEC высокопроизводительные концевые и торцевые фрезы

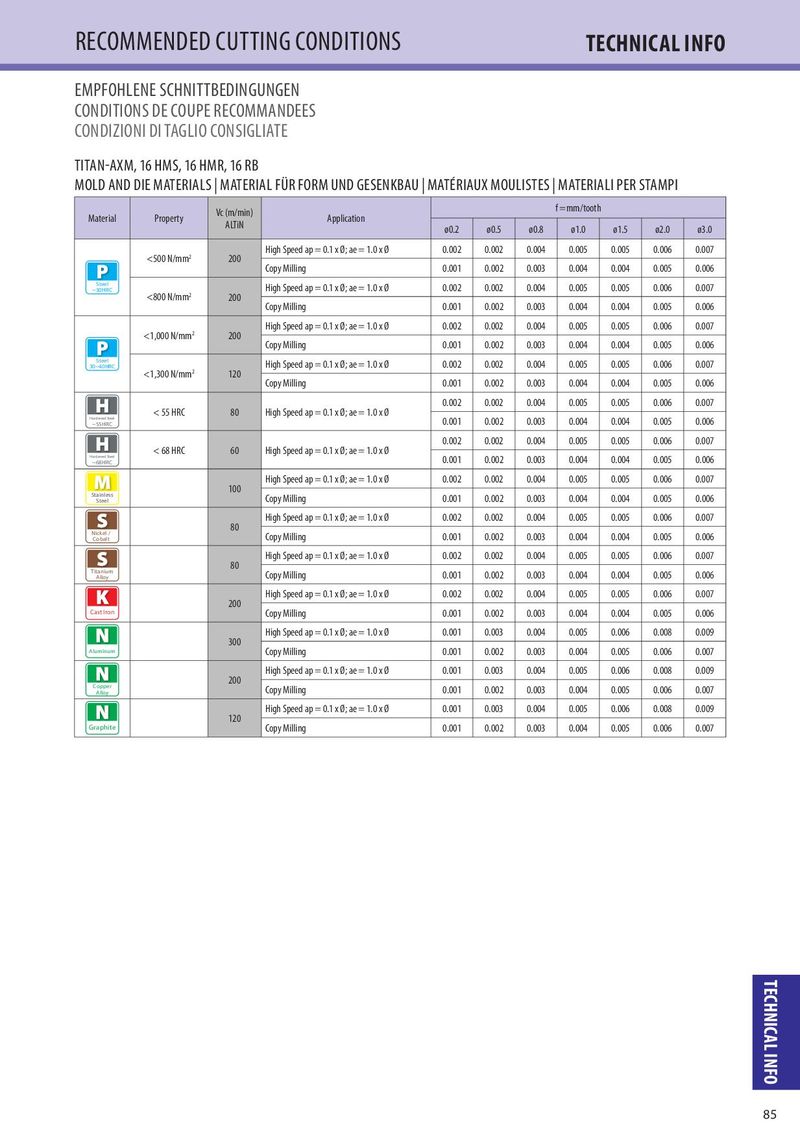

RECOMMENDED CUTTING CONDITIONS TECHNICAL INFO EMPFOHLENE SCHNITTBEDINGUNGEN CONDITIONS DE COUPE RECOMMANDEES CONDIZIONI DI TAGLIO CONSIGLIATE TITAN-AXM, 16 HMS, 16 HMR, 16 RB MOLD AND DIE MATERIALS | MATERIAL FÜR FORM UND GESENKBAU | MATÉRIAUX MOULISTES | MATERIALI PER STAMPI f Vc (m/min) = mm/tooth Material Property Application ALTiN ø0.2 ø0.5 ø0.8 ø1.0 ø1.5 ø2.0 ø3.0 High Speed ap = 0.1 x Ø; ae = 1.0 x Ø 0.002 0.002 0.004 0.005 0.005 0.006 0.007 <500 N/mm 2 200 Copy Milling 0.001 0.002 0.003 0.004 0.004 0.005 0.006 Steel ~30HRC High Speed ap = 0.1 x Ø; ae = 1.0 x Ø 0.002 0.002 0.004 0.005 0.005 0.006 0.007 <800 N/mm 2 200 Copy Milling 0.001 0.002 0.003 0.004 0.004 0.005 0.006 High Speed ap = 0.1 x Ø; ae = 1.0 x Ø 0.002 0.002 0.004 0.005 0.005 0.006 0.007 <1,000 N/mm 2 200 Copy Milling 0.001 0.002 0.003 0.004 0.004 0.005 0.006 Steel 30~40HRC High Speed ap = 0.1 x Ø; ae = 1.0 x Ø 0.002 0.002 0.004 0.005 0.005 0.006 0.007 <1,300 N/mm 2 120 Copy Milling 0.001 0.002 0.003 0.004 0.004 0.005 0.006 0.002 0.002 0.004 0.005 0.005 0.006 0.007 < 55 HRC 80 High Speed ap = 0.1 x Ø; ae = 1.0 x Ø Hardened Steel ~55HRC 0.001 0.002 0.003 0.004 0.004 0.005 0.006 0.002 0.002 0.004 0.005 0.005 0.006 0.007 < 68 HRC 60 High Speed ap = 0.1 x Ø; ae = 1.0 x Ø Hardened Steel ~68HRC 0.001 0.002 0.003 0.004 0.004 0.005 0.006 High Speed ap = 0.1 x Ø; ae = 1.0 x Ø 0.002 0.002 0.004 0.005 0.005 0.006 0.007 100 Stainless Steel Copy Milling 0.001 0.002 0.003 0.004 0.004 0.005 0.006 High Speed ap = 0.1 x Ø; ae = 1.0 x Ø 0.002 0.002 0.004 0.005 0.005 0.006 0.007 80 Nickel / Cobalt Copy Milling 0.001 0.002 0.003 0.004 0.004 0.005 0.006 High Speed ap = 0.1 x Ø; ae = 1.0 x Ø 0.002 0.002 0.004 0.005 0.005 0.006 0.007 80 Titanium Alloy Copy Milling 0.001 0.002 0.003 0.004 0.004 0.005 0.006 High Speed ap = 0.1 x Ø; ae = 1.0 x Ø 0.002 0.002 0.004 0.005 0.005 0.006 0.007 200 Cast Iron Copy Milling 0.001 0.002 0.003 0.004 0.004 0.005 0.006 High Speed ap = 0.1 x Ø; ae = 1.0 x Ø 0.001 0.003 0.004 0.005 0.006 0.008 0.009 300 Aluminum Copy Milling 0.001 0.002 0.003 0.004 0.005 0.006 0.007 High Speed ap = 0.1 x Ø; ae = 1.0 x Ø 0.001 0.003 0.004 0.005 0.006 0.008 0.009 200 Copper Alloy Copy Milling 0.001 0.002 0.003 0.004 0.005 0.006 0.007 High Speed ap = 0.1 x Ø; ae = 1.0 x Ø 0.001 0.003 0.004 0.005 0.006 0.008 0.009 120 Graphite Copy Milling 0.001 0.002 0.003 0.004 0.005 0.006 0.007 TECHNICAL INFO 85 2015_KUTDE_MIT_Catalog_TZZ00058.indd 85 04.03.2016 07:54:21