Каталог Iscar вращающийся инструмент 2017 - страница 972

Навигация

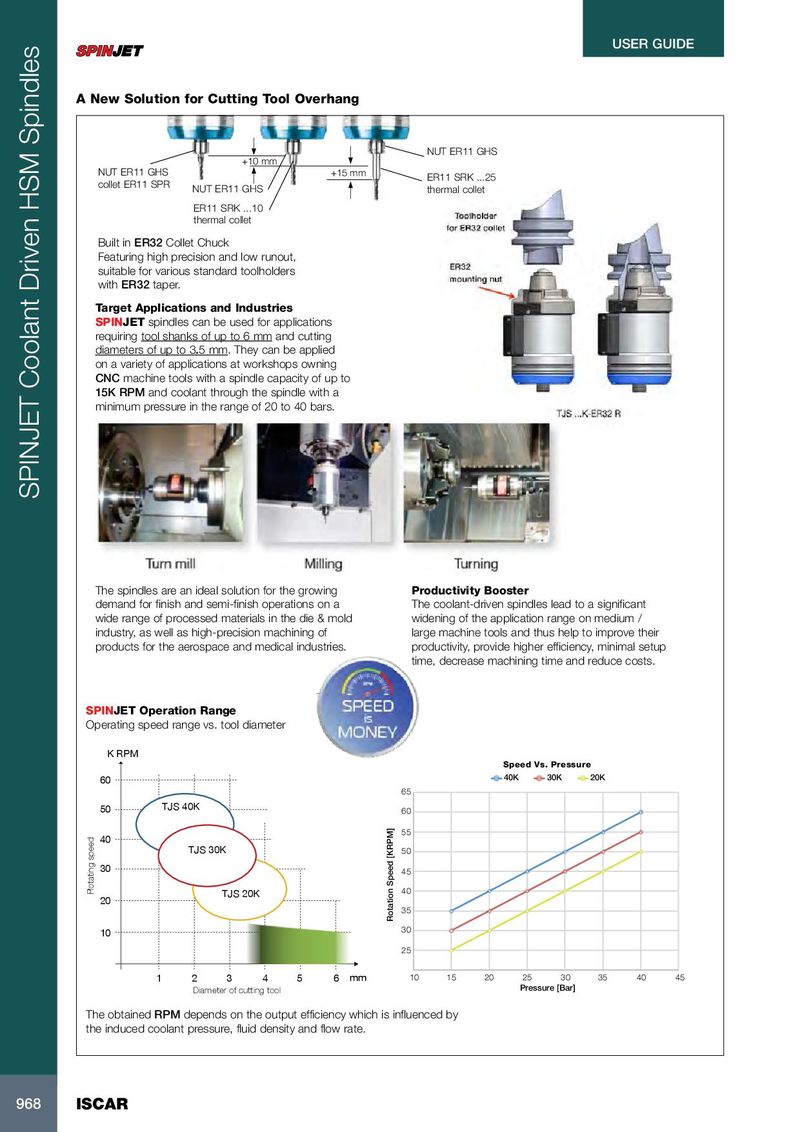

USER GUIDE A New Solution for Cutting Tool Overhang NUT ER11 GHS +10 mm NUT ER11 GHS +15 mm ER11 SRK ...25 collet ER11 SPR NUT ER11 GHS thermal collet ER11 SRK ...10 thermal collet Built in ER32 Collet Chuck Featuring high precision and low runout, suitable for various standard toolholders with ER32 taper. Target Applications and Industries SPINJET spindles can be used for applications requiring tool shanks of up to 6 mm and cutting diameters of up to 3.5 mm. They can be applied on a variety of applications at workshops owning CNC machine tools with a spindle capacity of up to 15K RPM and coolant through the spindle with a minimum pressure in the range of 20 to 40 bars. SPINJET Coolant Driven HSM Spindles The spindles are an ideal solution for the growing Productivity Booster demand for finish and semi-finish operations on a The coolant-driven spindles lead to a significant wide range of processed materials in the die & mold widening of the application range on medium / industry, as well as high-precision machining of large machine tools and thus help to improve their products for the aerospace and medical industries. productivity, provide higher efficiency, minimal setup time, decrease machining time and reduce costs. SPINJET Operation Range Operating speed range vs. tool diameter K RPM Speed Vs. Pressure 60 40K 30K 20K 65 50 TJS 40K 60 55 40 TJS 30K 50 30 45 Rotating speed TJS 20K 40 20 35 Rotation Speed [KRPM] 10 30 machine spindle 25 1 2 3 4 5 6 mm 10 15 20 25 30 35 40 45 Diameter of cutting tool Pressure [Bar] The obtained RPM depends on the output efficiency which is influenced by the induced coolant pressure, fluid density and flow rate. 968 ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022