Каталог Iscar вращающийся инструмент 2017 - страница 594

Навигация

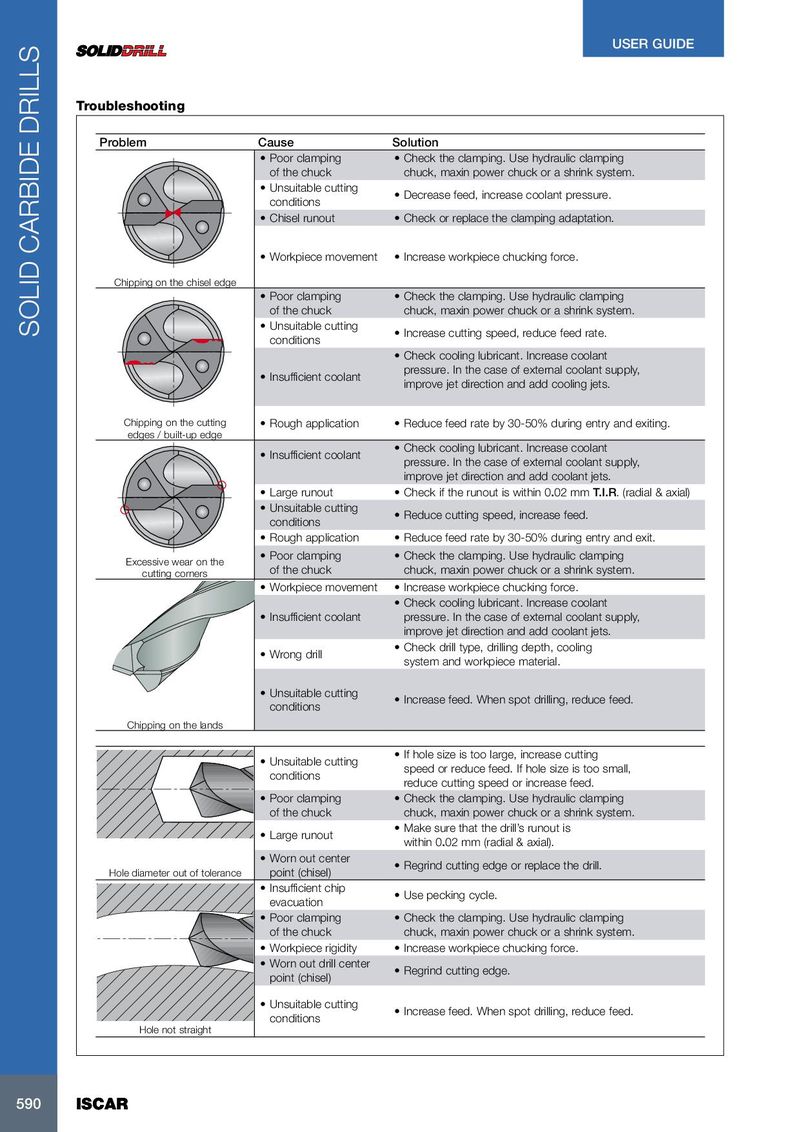

USER GUIDE Troubleshooting Problem Cause Solution • Poor clamping • Check the clamping. Use hydraulic clamping of the chuck chuck, maxin power chuck or a shrink system. • Unsuitable cutting • Decrease feed, increase coolant pressure. conditions • Chisel runout • Check or replace the clamping adaptation. • Workpiece movement • Increase workpiece chucking force. Chipping on the chisel edge • Poor clamping • Check the clamping. Use hydraulic clamping of the chuck chuck, maxin power chuck or a shrink system. • Unsuitable cutting SOLID CARBIDE DRILLS • Increase cutting speed, reduce feed rate. conditions • Check cooling lubricant. Increase coolant pressure. In the case of external coolant supply, • Insufficient coolant improve jet direction and add cooling jets. Chipping on the cutting • Rough application • Reduce feed rate by 30-50% during entry and exiting. edges / built-up edge • Check cooling lubricant. Increase coolant • Insufficient coolant pressure. In the case of external coolant supply, improve jet direction and add coolant jets. • Large runout • Check if the runout is within 0.02 mm T.I.R. (radial & axial) • Unsuitable cutting • Reduce cutting speed, increase feed. conditions • Rough application • Reduce feed rate by 30-50% during entry and exit. • Poor clamping • Check the clamping. Use hydraulic clamping Excessive wear on the cutting corners of the chuck chuck, maxin power chuck or a shrink system. • Workpiece movement • Increase workpiece chucking force. • Check cooling lubricant. Increase coolant • Insufficient coolant pressure. In the case of external coolant supply, improve jet direction and add coolant jets. • Check drill type, drilling depth, cooling • Wrong drill system and workpiece material. • Unsuitable cutting • Increase feed. When spot drilling, reduce feed. conditions Chipping on the lands • If hole size is too large, increase cutting • Unsuitable cutting speed or reduce feed. If hole size is too small, conditions reduce cutting speed or increase feed. • Poor clamping • Check the clamping. Use hydraulic clamping of the chuck chuck, maxin power chuck or a shrink system. • Make sure that the drill’s runout is • Large runout within 0.02 mm (radial & axial). • Worn out center • Regrind cutting edge or replace the drill. Hole diameter out of tolerance point (chisel) • Insufficient chip • Use pecking cycle. evacuation • Poor clamping • Check the clamping. Use hydraulic clamping of the chuck chuck, maxin power chuck or a shrink system. • Workpiece rigidity • Increase workpiece chucking force. • Worn out drill center • Regrind cutting edge. point (chisel) • Unsuitable cutting • Increase feed. When spot drilling, reduce feed. conditions Hole not straight 590 590 ISCAR ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022