Каталог Iscar вращающийся инструмент 2017 - страница 587

Навигация

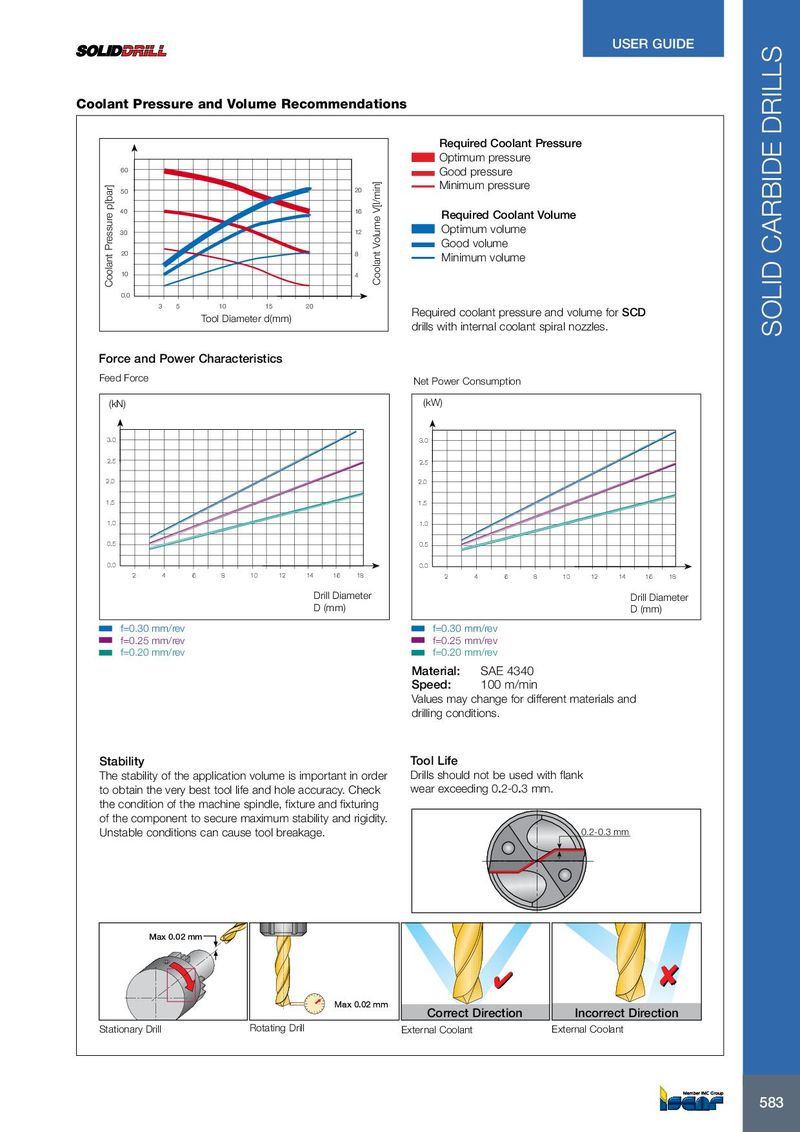

USER GUIDE Coolant Pressure and Volume Recommendations Required Coolant Pressure Optimum pressure 60 Good pressure Minimum pressure 50 20 40 16 Required Coolant Volume 30 12 Optimum volume Good volume 20 8 Minimum volume 10 4 Coolant Pressure p[bar] Coolant Volume V[l/min] 0.0 3 5 10 15 20 Required coolant pressure and volume for SCD Tool Diameter d(mm) drills with internal coolant spiral nozzles. SOLID CARBIDE DRILLS Force and Power Characteristics Feed Force Net Power Consumption (kN) (kW) 3.0 3.0 2.5 2.5 2.0 2.0 1.5 1.5 1.0 1.0 0.5 0.5 0.0 0.0 2 4 6 8 10 12 14 16 18 2 4 6 8 10 12 14 16 18 Drill Diameter Drill Diameter D (mm) D (mm) f=0.30 mm/rev f=0.30 mm/rev f=0.25 mm/rev f=0.25 mm/rev f=0.20 mm/rev f=0.20 mm/rev Material: SAE 4340 Speed: 100 m/min Values may change for different materials and drilling conditions. Stability Tool Life The stability of the application volume is important in order Drills should not be used with flank to obtain the very best tool life and hole accuracy. Check wear exceeding 0.2-0.3 mm. the condition of the machine spindle, fixture and fixturing of the component to secure maximum stability and rigidity. Unstable conditions can cause tool breakage. 0.2-0.3 mm Max 0.02 mm Max 0.02 mm Correct Direction Incorrect Direction Stationary Drill Rotating Drill External Coolant External Coolant 583 583

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022