Каталог Iscar вращающийся инструмент 2017 - страница 556

Навигация

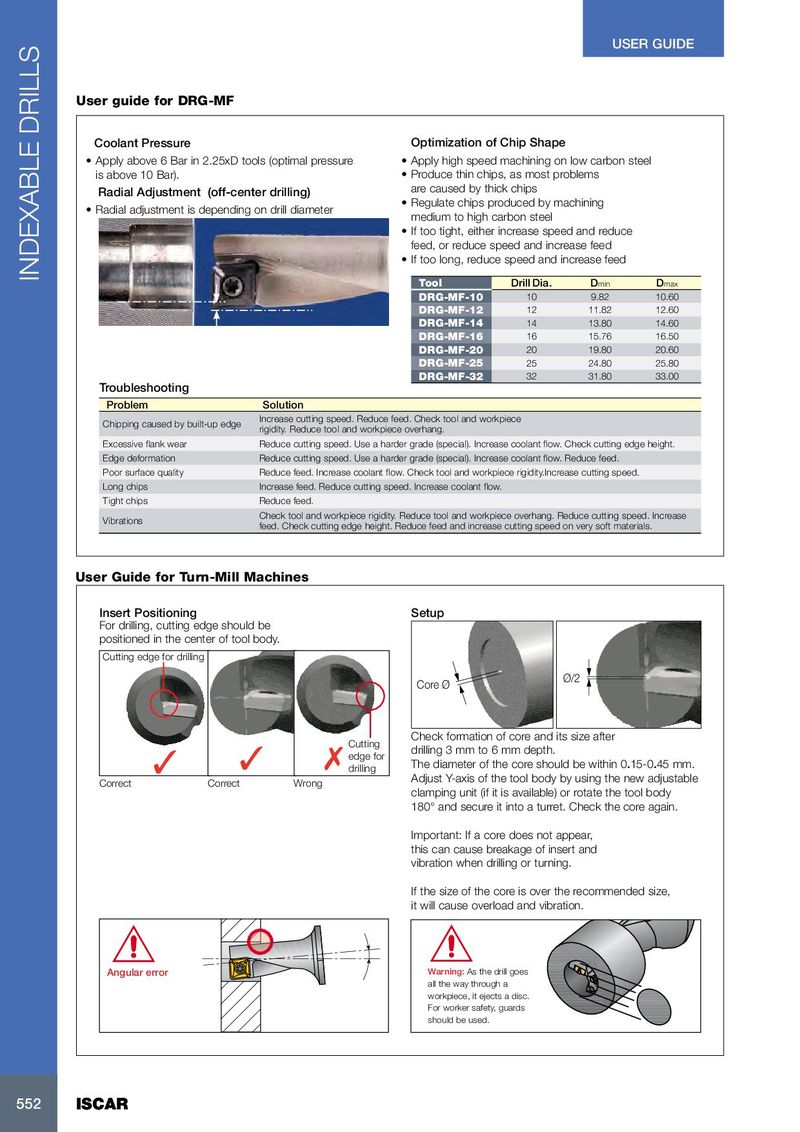

USER GUIDE User guide for DRG-MF Coolant Pressure Optimization of Chip Shape • Apply above 6 Bar in 2.25xD tools (optimal pressure • Apply high speed machining on low carbon steel is above 10 Bar). • Produce thin chips, as most problems Radial Adjustment (off-center drilling) are caused by thick chips • Regulate chips produced by machining • Radial adjustment is depending on drill diameter medium to high carbon steel • If too tight, either increase speed and reduce feed, or reduce speed and increase feed • If too long, reduce speed and increase feed INDEXABLE DRILLS Tool Drill Dia. D min D max DRG-MF-10 10 9.82 10.60 DRG-MF-12 12 11.82 12.60 DRG-MF-14 14 13.80 14.60 DRG-MF-16 16 15.76 16.50 DRG-MF-20 20 19.80 20.60 DRG-MF-25 25 24.80 25.80 DRG-MF-32 32 31.80 33.00 Troubleshooting Problem Solution Increase cutting speed. Reduce feed. Check tool and workpiece Chipping caused by built-up edge rigidity. Reduce tool and workpiece overhang. Excessive flank wear Reduce cutting speed. Use a harder grade (special). Increase coolant flow. Check cutting edge height. Edge deformation Reduce cutting speed. Use a harder grade (special). Increase coolant flow. Reduce feed. Poor surface quality Reduce feed. Increase coolant flow. Check tool and workpiece rigidity.Increase cutting speed. Long chips Increase feed. Reduce cutting speed. Increase coolant flow. Tight chips Reduce feed. Check tool and workpiece rigidity. Reduce tool and workpiece overhang. Reduce cutting speed. Increase Vibrations feed. Check cutting edge height. Reduce feed and increase cutting speed on very soft materials. User Guide for Turn-Mill Machines Insert Positioning Setup For drilling, cutting edge should be positioned in the center of tool body. Cutting edge for drilling Ø/2 Core Ø Check formation of core and its size after Cutting drilling 3 mm to 6 mm depth. edge for ✓ ✗ The diameter of the core should be within 0.15-0.45 mm. ✓ drilling Adjust Y-axis of the tool body by using the new adjustable Correct Correct Wrong clamping unit (if it is available) or rotate the tool body 180° and secure it into a turret. Check the core again. Important: If a core does not appear, this can cause breakage of insert and vibration when drilling or turning. If the size of the core is over the recommended size, it will cause overload and vibration. Angular error Warning: As the drill goes all the way through a workpiece, it ejects a disc. For worker safety, guards should be used. 552 552 ISCAR ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022