Каталог Iscar вращающийся инструмент 2017 - страница 552

Навигация

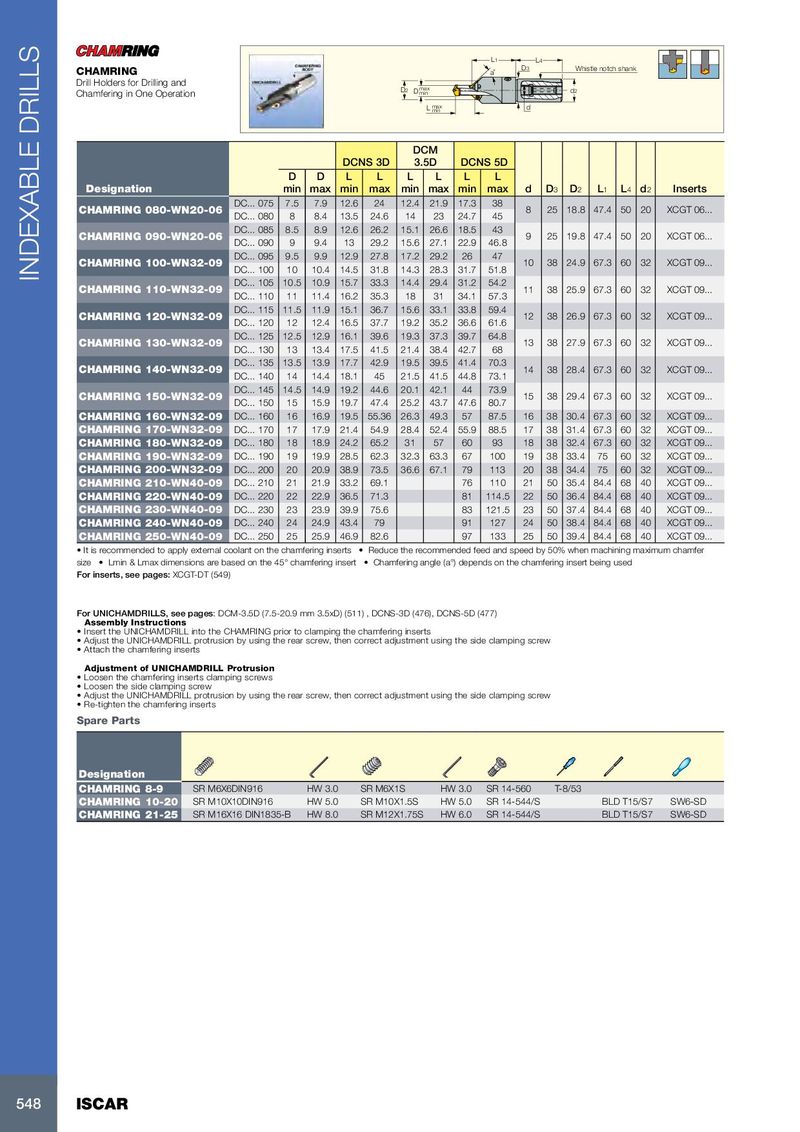

L1 L4 D3 a˚ Whistle notch shank CHAMRING Drill Holders for Drilling and D2 Chamfering in One Operation D max min d2 L max min d DCM DCNS 3D 3.5D DCNS 5D D D L L L L L L Designation min max min max min max min max d D 3 D 2 L 1 L 4 d 2 Inserts DC... 075 7.5 7.9 12.6 24 12.4 21.9 17.3 38 CHAMRING 080-WN20-06 8 25 18.8 47.4 50 20 XCGT 06... DC... 080 8 8.4 13.5 24.6 14 23 24.7 45 DC... 085 8.5 8.9 12.6 26.2 15.1 26.6 18.5 43 CHAMRING 090-WN20-06 9 25 19.8 47.4 50 20 XCGT 06... DC... 090 9 9.4 13 29.2 15.6 27.1 22.9 46.8 DC... 095 9.5 9.9 12.9 27.8 17.2 29.2 26 47 CHAMRING 100-WN32-09 10 38 24.9 67.3 60 32 XCGT 09... DC... 100 10 10.4 14.5 31.8 14.3 28.3 31.7 51.8 INDEXABLE DRILLS DC... 105 10.5 10.9 15.7 33.3 14.4 29.4 31.2 54.2 CHAMRING 110-WN32-09 11 38 25.9 67.3 60 32 XCGT 09... DC... 110 11 11.4 16.2 35.3 18 31 34.1 57.3 DC... 115 11.5 11.9 15.1 36.7 15.6 33.1 33.8 59.4 CHAMRING 120-WN32-09 12 38 26.9 67.3 60 32 XCGT 09... DC... 120 12 12.4 16.5 37.7 19.2 35.2 36.6 61.6 DC... 125 12.5 12.9 16.1 39.6 19.3 37.3 39.7 64.8 CHAMRING 130-WN32-09 13 38 27.9 67.3 60 32 XCGT 09... DC... 130 13 13.4 17.5 41.5 21.4 38.4 42.7 68 DC... 135 13.5 13.9 17.7 42.9 19.5 39.5 41.4 70.3 CHAMRING 140-WN32-09 14 38 28.4 67.3 60 32 XCGT 09... DC... 140 14 14.4 18.1 45 21.5 41.5 44.8 73.1 DC... 145 14.5 14.9 19.2 44.6 20.1 42.1 44 73.9 CHAMRING 150-WN32-09 15 38 29.4 67.3 60 32 XCGT 09... DC... 150 15 15.9 19.7 47.4 25.2 43.7 47.6 80.7 CHAMRING 160-WN32-09 DC... 160 16 16.9 19.5 55.36 26.3 49.3 57 87.5 16 38 30.4 67.3 60 32 XCGT 09... CHAMRING 170-WN32-09 DC... 170 17 17.9 21.4 54.9 28.4 52.4 55.9 88.5 17 38 31.4 67.3 60 32 XCGT 09... CHAMRING 180-WN32-09 DC... 180 18 18.9 24.2 65.2 31 57 60 93 18 38 32.4 67.3 60 32 XCGT 09... CHAMRING 190-WN32-09 DC... 190 19 19.9 28.5 62.3 32.3 63.3 67 100 19 38 33.4 75 60 32 XCGT 09... CHAMRING 200-WN32-09 DC... 200 20 20.9 38.9 73.5 36.6 67.1 79 113 20 38 34.4 75 60 32 XCGT 09... CHAMRING 210-WN40-09 DC... 210 21 21.9 33.2 69.1 76 110 21 50 35.4 84.4 68 40 XCGT 09... CHAMRING 220-WN40-09 DC... 220 22 22.9 36.5 71.3 81 114.5 22 50 36.4 84.4 68 40 XCGT 09... CHAMRING 230-WN40-09 DC... 230 23 23.9 39.9 75.6 83 121.5 23 50 37.4 84.4 68 40 XCGT 09... CHAMRING 240-WN40-09 DC... 240 24 24.9 43.4 79 91 127 24 50 38.4 84.4 68 40 XCGT 09... CHAMRING 250-WN40-09 DC... 250 25 25.9 46.9 82.6 97 133 25 50 39.4 84.4 68 40 XCGT 09... • It is recommended to apply external coolant on the chamfering inserts • Reduce the recommended feed and speed by 50% when machining maximum chamfer size • Lmin & Lmax dimensions are based on the 45° chamfering insert • Chamfering angle (a°) depends on the chamfering insert being used For inserts, see pages: XCGT-DT (549) For UNICHAMDRILLS, see pages: DCM-3.5D (7.5-20.9 mm 3.5xD) (511) , DCNS-3D (476), DCNS-5D (477) Assembly Instructions • Insert the UNICHAMDRILL into the CHAMRING prior to clamping the chamfering inserts • Adjust the UNICHAMDRILL protrusion by using the rear screw, then correct adjustment using the side clamping screw • Attach the chamfering inserts Adjustment of UNICHAMDRILL Protrusion • Loosen the chamfering inserts clamping screws • Loosen the side clamping screw • Adjust the UNICHAMDRILL protrusion by using the rear screw, then correct adjustment using the side clamping screw • Re-tighten the chamfering inserts Spare Parts Designation CHAMRING 8-9 SR M6X6DIN916 HW 3.0 SR M6X1S HW 3.0 SR 14-560 T-8/53 CHAMRING 10-20 SR M10X10DIN916 HW 5.0 SR M10X1.5S HW 5.0 SR 14-544/S BLD T15/S7 SW6-SD CHAMRING 21-25 SR M16X16 DIN1835-B HW 8.0 SR M12X1.75S HW 6.0 SR 14-544/S BLD T15/S7 SW6-SD 548 ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022