Каталог Iscar вращающийся инструмент 2017 - страница 322

Навигация

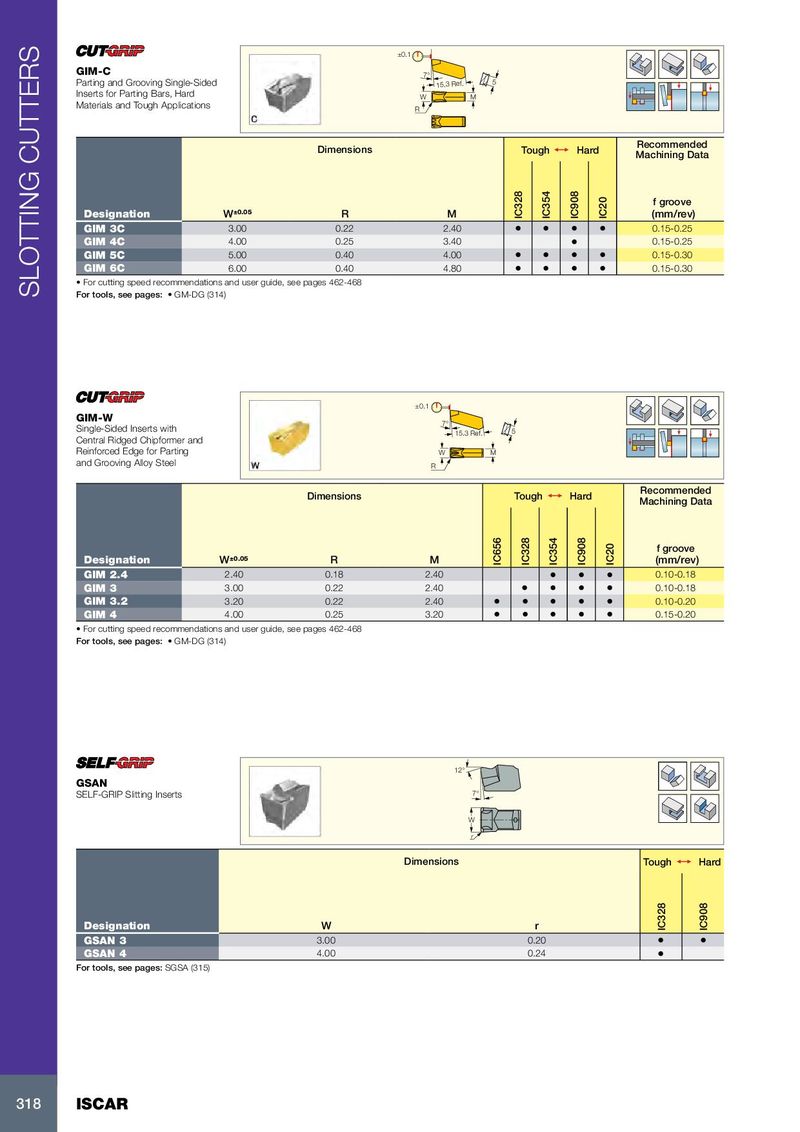

±0.1 GIM-C 7° Parting and Grooving Single-Sided 15.3 Ref. 5 Inserts for Parting Bars, Hard W M Materials and Tough Applications R Recommended Dimensions Tough 1 Hard Machining Data f groove Designation W ±0.05 R M IC328 IC354 IC908 IC20 (mm/rev) GIM 3C 3.00 0.22 2.40 • • • • 0.15-0.25 GIM 4C 4.00 0.25 3.40 • 0.15-0.25 GIM 5C 5.00 0.40 4.00 • • • • 0.15-0.30 GIM 6C 6.00 0.40 4.80 • • • • 0.15-0.30 • For cutting speed recommendations and user guide, see pages 462-468 SLOTTING CUTTERS For tools, see pages: • GM-DG (314) ±0.1 GIM-W 7° Single-Sided Inserts with 15.3 Ref. 5 Central Ridged Chipformer and Reinforced Edge for Parting W M and Grooving Alloy Steel R Recommended Dimensions Tough 1 Hard Machining Data f groove Designation W ±0.05 R M IC656 IC328 IC354 IC908 IC20 (mm/rev) GIM 2.4 2.40 0.18 2.40 • • • 0.10-0.18 GIM 3 3.00 0.22 2.40 • • • • 0.10-0.18 GIM 3.2 3.20 0.22 2.40 • • • • • 0.10-0.20 GIM 4 4.00 0.25 3.20 • • • • • 0.15-0.20 • For cutting speed recommendations and user guide, see pages 462-468 For tools, see pages: • GM-DG (314) 12° GSAN SELF-GRIP Slitting Inserts 7° W r Dimensions Tough 1 Hard Designation W r IC328 IC908 GSAN 3 3.00 0.20 • • GSAN 4 4.00 0.24 • For tools, see pages: SGSA (315) 318 ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022