Каталог Iscar вращающийся инструмент 2017 - страница 317

Навигация

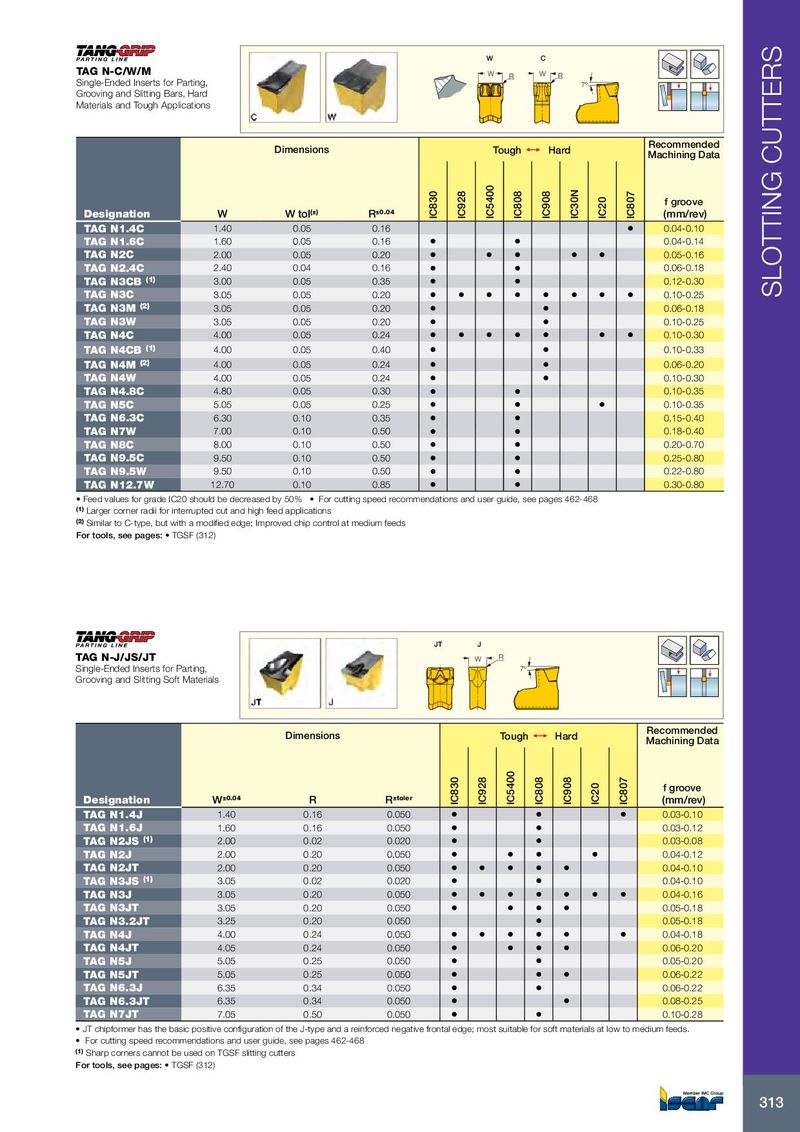

W C TAG N-C/W/M W R W R Single-Ended Inserts for Parting, 7º Grooving and Slitting Bars, Hard Materials and Tough Applications Recommended Dimensions Tough 1 Hard Machining Data f groove Designation W W tol (±) R ±0.04 IC830 IC928 IC5400 IC808 IC908 IC30N IC20 IC807 (mm/rev) TAG N1.4C 1.40 0.05 0.16 • 0.04-0.10 TAG N1.6C 1.60 0.05 0.16 • • 0.04-0.14 TAG N2C 2.00 0.05 0.20 • • • • • 0.05-0.16 TAG N2.4C 2.40 0.04 0.16 • • 0.06-0.18 TAG N3CB (1) 3.00 0.05 0.35 • • 0.12-0.30 TAG N3C 3.05 0.05 0.20 • • • • • • • • 0.10-0.25 SLOTTING CUTTERS TAG N3M (2) 3.05 0.05 0.20 • • 0.06-0.18 TAG N3W 3.05 0.05 0.20 • • 0.10-0.25 TAG N4C 4.00 0.05 0.24 • • • • • • • 0.10-0.30 TAG N4CB (1) 4.00 0.05 0.40 • • 0.10-0.33 TAG N4M (2) 4.00 0.05 0.24 • • 0.06-0.20 TAG N4W 4.00 0.05 0.24 • • 0.10-0.30 TAG N4.8C 4.80 0.05 0.30 • • 0.10-0.35 TAG N5C 5.05 0.05 0.25 • • • 0.10-0.35 TAG N6.3C 6.30 0.10 0.35 • • 0.15-0.40 TAG N7W 7.00 0.10 0.50 • • 0.18-0.40 TAG N8C 8.00 0.10 0.50 • • 0.20-0.70 TAG N9.5C 9.50 0.10 0.50 • • 0.25-0.80 TAG N9.5W 9.50 0.10 0.50 • • 0.22-0.80 TAG N12.7W 12.70 0.10 0.85 • • 0.30-0.80 • Feed values for grade IC20 should be decreased by 50% • For cutting speed recommendations and user guide, see pages 462-468 (1) Larger corner radii for interrupted cut and high feed applications (2) Similar to C-type, but with a modified edge; Improved chip control at medium feeds For tools, see pages: • TGSF (312) JT J TAG N-J/JS/JT W R Single-Ended Inserts for Parting, 7º Grooving and Slitting Soft Materials Recommended Dimensions Tough 1 Hard Machining Data f groove Designation W ±0.04 R R ±toler IC830 IC928 IC5400 IC808 IC908 IC20 IC807 (mm/rev) TAG N1.4J 1.40 0.16 0.050 • • • 0.03-0.10 TAG N1.6J 1.60 0.16 0.050 • • 0.03-0.12 TAG N2JS (1) 2.00 0.02 0.020 • • 0.03-0.08 TAG N2J 2.00 0.20 0.050 • • • • 0.04-0.12 TAG N2JT 2.00 0.20 0.050 • • • • • 0.04-0.10 TAG N3JS (1) 3.05 0.02 0.020 • • 0.04-0.10 TAG N3J 3.05 0.20 0.050 • • • • • • • 0.04-0.16 TAG N3JT 3.05 0.20 0.050 • • • • 0.05-0.18 TAG N3.2JT 3.25 0.20 0.050 • 0.05-0.18 TAG N4J 4.00 0.24 0.050 • • • • • • 0.04-0.18 TAG N4JT 4.05 0.24 0.050 • • • • 0.06-0.20 TAG N5J 5.05 0.25 0.050 • • 0.05-0.20 TAG N5JT 5.05 0.25 0.050 • • • 0.06-0.22 TAG N6.3J 6.35 0.34 0.050 • • 0.06-0.22 TAG N6.3JT 6.35 0.34 0.050 • • 0.08-0.25 TAG N7JT 7.05 0.50 0.050 • • 0.10-0.28 • JT chipformer has the basic positive configuration of the J-type and a reinforced negative frontal edge; most suitable for soft materials at low to medium feeds. • For cutting speed recommendations and user guide, see pages 462-468 (1) Sharp corners cannot be used on TGSF slitting cutters For tools, see pages: • TGSF (312) 313

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022