Каталог Iscar вращающийся инструмент 2017 - страница 293

Навигация

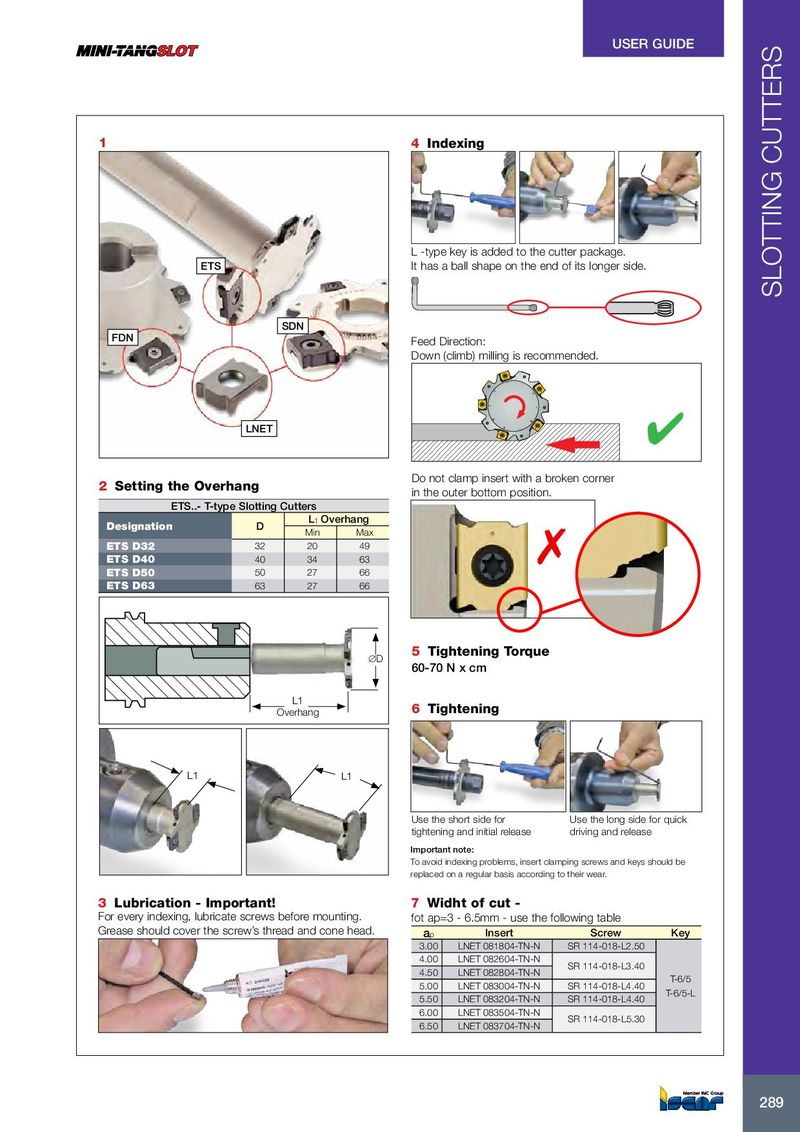

USER GUIDE 1 4 Indexing L -type key is added to the cutter package. ETS It has a ball shape on the end of its longer side. SLOTTING CUTTERS SDN FDN Feed Direction: Down (climb) milling is recommended. LNET ✔ Do not clamp insert with a broken corner 2 Setting the Overhang in the outer bottom position. ETS..- T-type Slotting Cutters L 1 Overhang Designation D Min Max ETS D32 32 20 49 ETS D40 40 34 63 ✗ ETS D50 50 27 66 ETS D63 63 27 66 5 Tightening Torque ∅D 60-70 N x cm L1 Overhang 6 Tightening L1 L1 Use the short side for Use the long side for quick tightening and initial release driving and release Important note: To avoid indexing problems, insert clamping screws and keys should be replaced on a regular basis according to their wear. 3 Lubrication - Important! 7 Widht of cut - For every indexing, lubricate screws before mounting. fot ap=3 - 6.5mm - use the following table Grease should cover the screw’s thread and cone head. a p Insert Screw Key 3.00 LNET 081804-TN-N SR 114-018-L2.50 4.00 LNET 082604-TN-N SR 114-018-L3.40 4.50 LNET 082804-TN-N T-6/5 5.00 LNET 083004-TN-N SR 114-018-L4.40 T-6/5-L 5.50 LNET 083204-TN-N SR 114-018-L4.40 6.00 LNET 083504-TN-N SR 114-018-L5.30 6.50 LNET 083704-TN-N 289 289

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022