Каталог Iscar вращающийся инструмент 2017 - страница 258

Навигация

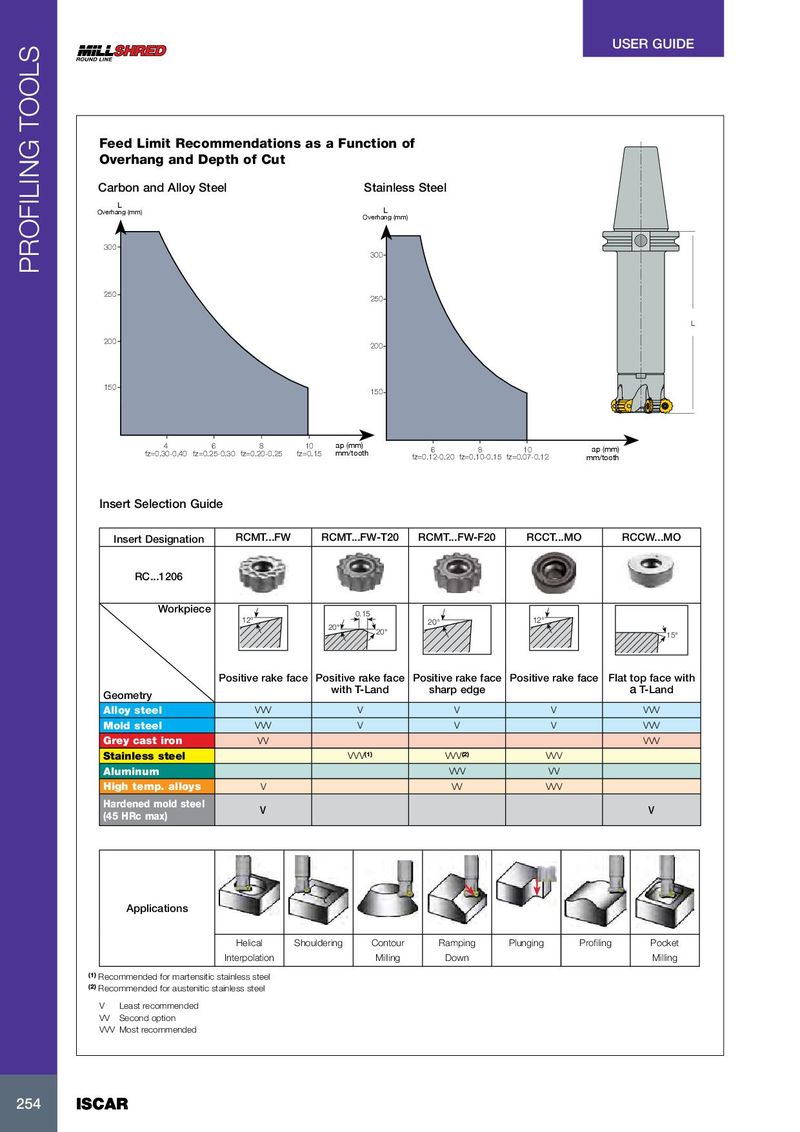

USER GUIDE Feed Limit Recommendations as a Function of Overhang and Depth of Cut Carbon and Alloy Steel Stainless Steel L Overhang (mm) L Overhang (mm) 300 300 PROFILING TOOLS 250 250 L 200 200 150 150 4 6 8 10 ap (mm) fz=0.30-0.40 fz=0.25-0.30 fz=0.20-0.25 fz=0.15 mm/tooth 6 8 10 ap (mm) fz=0.12-0.20 fz=0.10-0.15 fz=0.07-0.12 mm/tooth Insert Selection Guide Insert Designation RCMT...FW RCMT...FW-T20 RCMT...FW-F20 RCCT...MO RCCW...MO RC...1206 Workpiece 0.15 12° 20° 12° 20° 20° 15° Positive rake face Positive rake face Positive rake face Positive rake face Flat top face with with T-Land sharp edge a T-Land Geometry Alloy steel VVV V V V VVV Mold steel VVV V V V VVV Grey cast iron VV VVV Stainless steel VVV (1) VVV (2) VVV Aluminum VVV VV High temp. alloys V VV VVV Hardened mold steel V V (45 HRc max) Applications Helical Shouldering Contour Ramping Plunging Profiling Pocket Interpolation Milling Down Milling (1) Recommended for martensitic stainless steel (2) Recommended for austenitic stainless steel V Least recommended VV Second option VVV Most recommended 254 254 ISCAR ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022