Каталог Iscar вращающийся инструмент 2017 - страница 168

Навигация

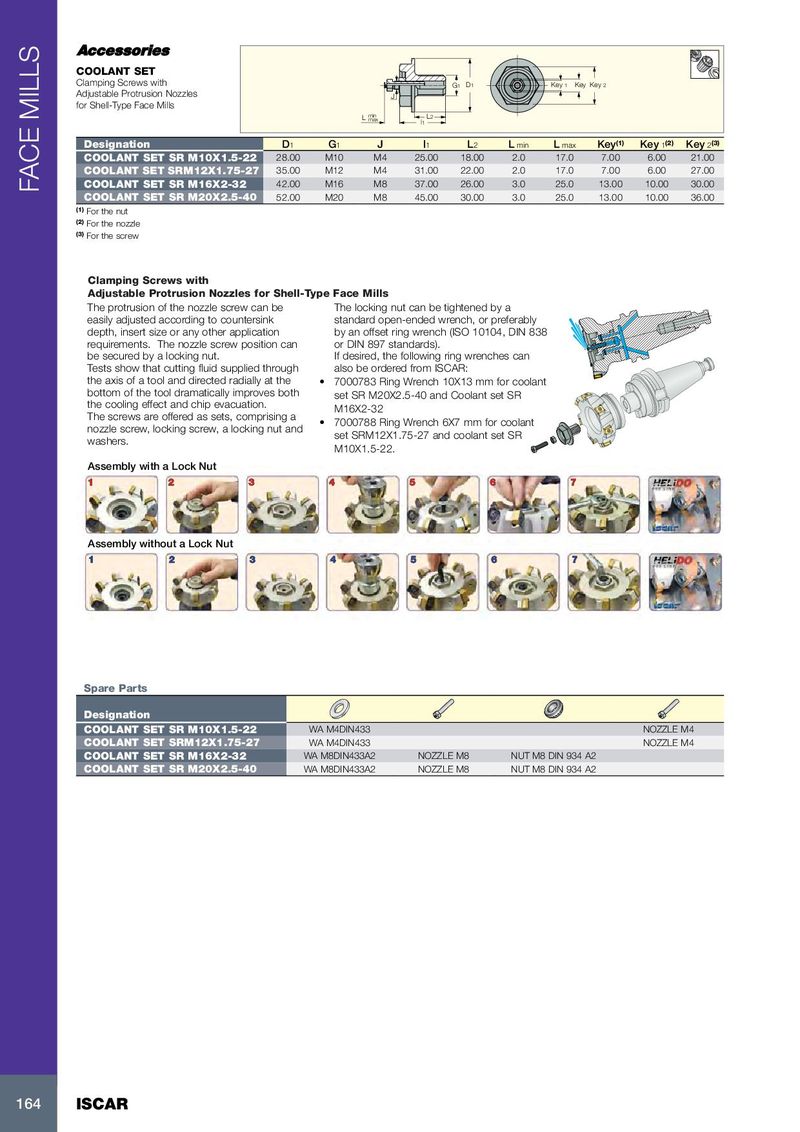

COOLANT SET Clamping Screws with G1 D1 Key 1 Key Key 2 Adjustable Protrusion Nozzles J for Shell-Type Face Mills L min max L2 l1 Designation D 1 G 1 J l 1 L 2 L min L max Key (1) Key 1 (2) Key 2 (3) COOLANT SET SR M10X1.5-22 28.00 M10 M4 25.00 18.00 2.0 17.0 7.00 6.00 21.00 COOLANT SET SRM12X1.75-27 35.00 M12 M4 31.00 22.00 2.0 17.0 7.00 6.00 27.00 COOLANT SET SR M16X2-32 42.00 M16 M8 37.00 26.00 3.0 25.0 13.00 10.00 30.00 FACE MILLS COOLANT SET SR M20X2.5-40 52.00 M20 M8 45.00 30.00 3.0 25.0 13.00 10.00 36.00 (1) For the nut (2) For the nozzle (3) For the screw Clamping Screws with Adjustable Protrusion Nozzles for Shell-Type Face Mills The protrusion of the nozzle screw can be The locking nut can be tightened by a easily adjusted according to countersink standard open-ended wrench, or preferably depth, insert size or any other application by an offset ring wrench (ISO 10104, DIN 838 requirements. The nozzle screw position can or DIN 897 standards). be secured by a locking nut. If desired, the following ring wrenches can Tests show that cutting fluid supplied through also be ordered from ISCAR: the axis of a tool and directed radially at the • 7000783 Ring Wrench 10X13 mm for coolant bottom of the tool dramatically improves both set SR M20X2.5-40 and Coolant set SR the cooling effect and chip evacuation. M16X2-32 The screws are offered as sets, comprising a • 7000788 Ring Wrench 6X7 mm for coolant nozzle screw, locking screw, a locking nut and set SRM12X1.75-27 and coolant set SR washers. M10X1.5-22. Assembly with a Lock Nut 1 2 3 4 5 6 7 7103284 06/08 Assembly without a Lock Nut 1 2 3 4 5 6 7 Spare Parts Designation COOLANT SET SR M10X1.5-22 WA M4DIN433 NOZZLE M4 COOLANT SET SRM12X1.75-27 WA M4DIN433 NOZZLE M4 COOLANT SET SR M16X2-32 WA M8DIN433A2 NOZZLE M8 NUT M8 DIN 934 A2 COOLANT SET SR M20X2.5-40 WA M8DIN433A2 NOZZLE M8 NUT M8 DIN 934 A2 164 ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022