Каталог Iscar вращающийся инструмент 2017 - страница 130

Навигация

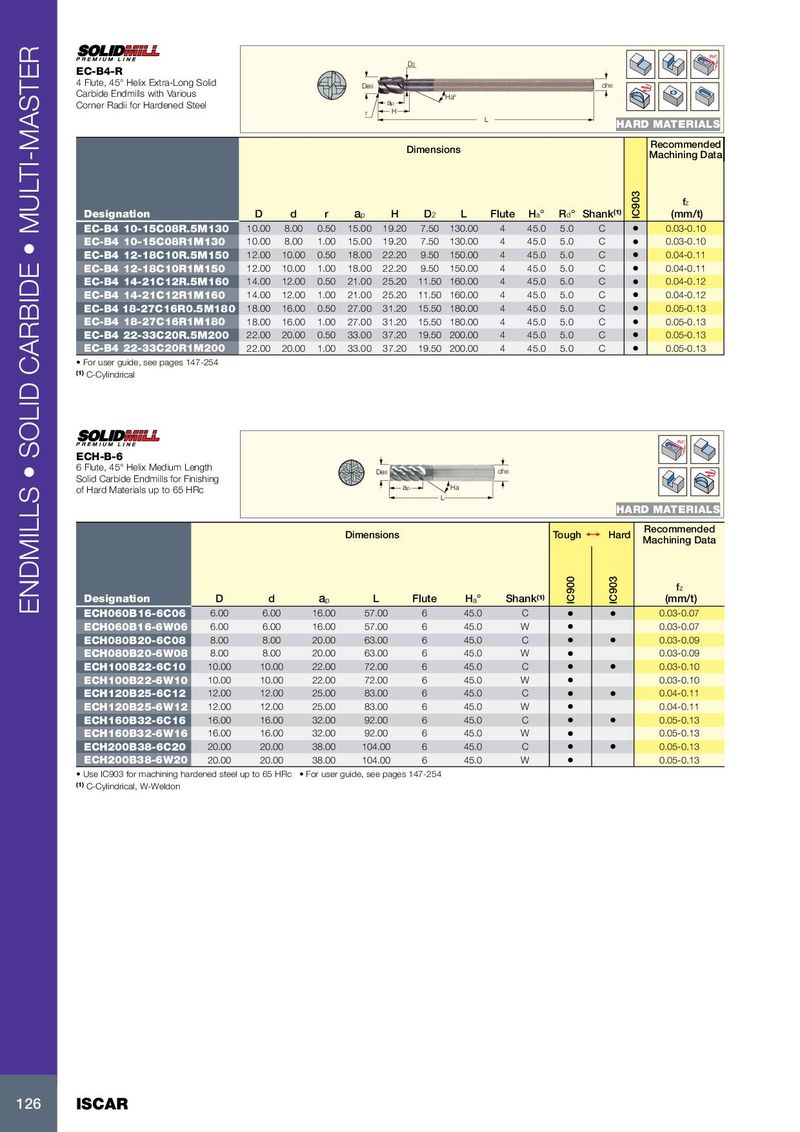

Rd° D2 EC-B4-R 4 Flute, 45° Helix Extra-Long Solid De8 dh6 Carbide Endmills with Various Haº Corner Radii for Hardened Steel ap r H L HARD MATERIALS Recommended Dimensions Machining Data f z Designation D d r a p H D 2 L Flute H a ° R d ° Shank (1) IC903 (mm/t) EC-B4 10-15C08R.5M130 10.00 8.00 0.50 15.00 19.20 7.50 130.00 4 45.0 5.0 C • 0.03-0.10 EC-B4 10-15C08R1M130 10.00 8.00 1.00 15.00 19.20 7.50 130.00 4 45.0 5.0 C • 0.03-0.10 EC-B4 12-18C10R.5M150 12.00 10.00 0.50 18.00 22.20 9.50 150.00 4 45.0 5.0 C • 0.04-0.11 EC-B4 12-18C10R1M150 12.00 10.00 1.00 18.00 22.20 9.50 150.00 4 45.0 5.0 C • 0.04-0.11 EC-B4 14-21C12R.5M160 14.00 12.00 0.50 21.00 25.20 11.50 160.00 4 45.0 5.0 C • 0.04-0.12 EC-B4 14-21C12R1M160 14.00 12.00 1.00 21.00 25.20 11.50 160.00 4 45.0 5.0 C • 0.04-0.12 EC-B4 18-27C16R0.5M180 18.00 16.00 0.50 27.00 31.20 15.50 180.00 4 45.0 5.0 C • 0.05-0.13 EC-B4 18-27C16R1M180 18.00 16.00 1.00 27.00 31.20 15.50 180.00 4 45.0 5.0 C • 0.05-0.13 EC-B4 22-33C20R.5M200 22.00 20.00 0.50 33.00 37.20 19.50 200.00 4 45.0 5.0 C • 0.05-0.13 EC-B4 22-33C20R1M200 22.00 20.00 1.00 33.00 37.20 19.50 200.00 4 45.0 5.0 C • 0.05-0.13 • For user guide, see pages 147-254 (1) C-Cylindrical Rd° ECH-B-6 6 Flute, 45° Helix Medium Length De8 dh6 Solid Carbide Endmills for Finishing of Hard Materials up to 65 HRc ap Ha L HARD MATERIALS Recommended Dimensions Tough 1 Hard Machining Data f z Designation D d a p L Flute H a ° Shank (1) IC900 IC903 (mm/t) ENDMILLS • SOLID CARBIDE • MULTI-MASTER ECH060B16-6C06 6.00 6.00 16.00 57.00 6 45.0 C • • 0.03-0.07 ECH060B16-6W06 6.00 6.00 16.00 57.00 6 45.0 W • 0.03-0.07 ECH080B20-6C08 8.00 8.00 20.00 63.00 6 45.0 C • • 0.03-0.09 ECH080B20-6W08 8.00 8.00 20.00 63.00 6 45.0 W • 0.03-0.09 ECH100B22-6C10 10.00 10.00 22.00 72.00 6 45.0 C • • 0.03-0.10 ECH100B22-6W10 10.00 10.00 22.00 72.00 6 45.0 W • 0.03-0.10 ECH120B25-6C12 12.00 12.00 25.00 83.00 6 45.0 C • • 0.04-0.11 ECH120B25-6W12 12.00 12.00 25.00 83.00 6 45.0 W • 0.04-0.11 ECH160B32-6C16 16.00 16.00 32.00 92.00 6 45.0 C • • 0.05-0.13 ECH160B32-6W16 16.00 16.00 32.00 92.00 6 45.0 W • 0.05-0.13 ECH200B38-6C20 20.00 20.00 38.00 104.00 6 45.0 C • • 0.05-0.13 ECH200B38-6W20 20.00 20.00 38.00 104.00 6 45.0 W • 0.05-0.13 • Use IC903 for machining hardened steel up to 65 HRc • For user guide, see pages 147-254 (1) C-Cylindrical, W-Weldon 126 ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022