Каталог Iscar токарный инструмент 2017 - страница 370

Навигация

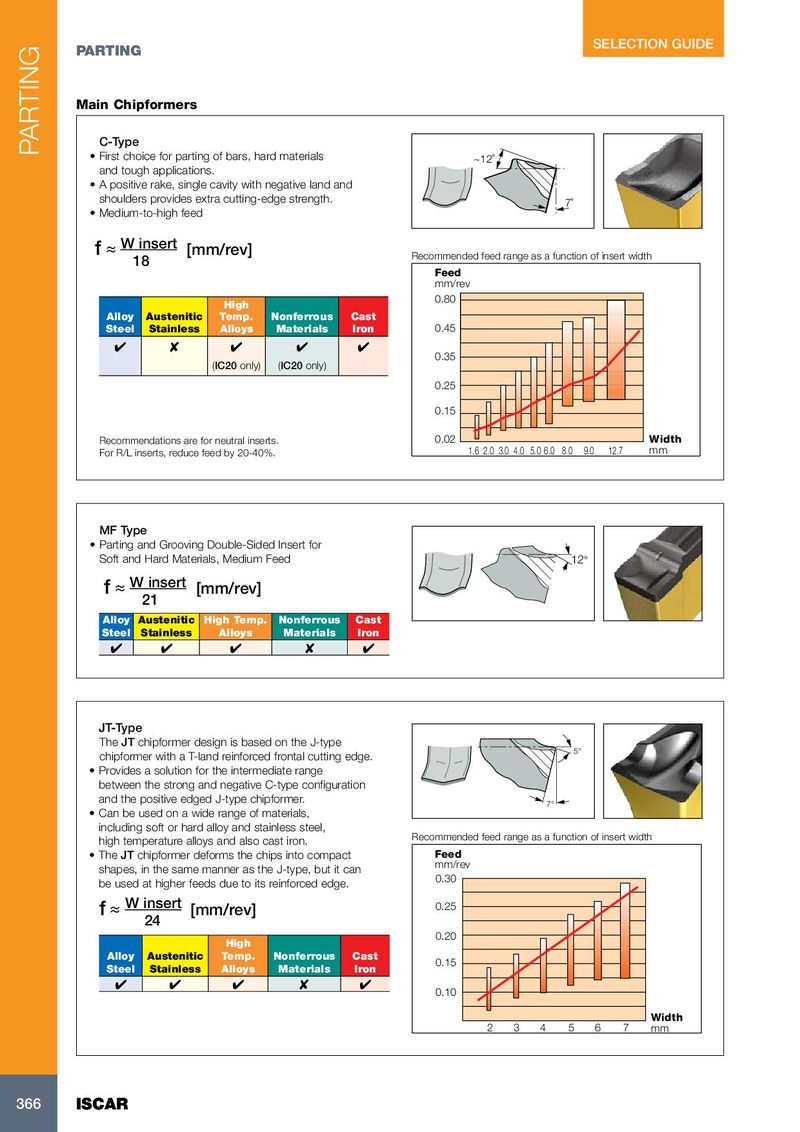

SELECTION GUIDE PARTING Main Chipformers C-Type PARTING • First choice for parting of bars, hard materials ~12˚ and tough applications. • A positive rake, single cavity with negative land and shoulders provides extra cutting-edge strength. 7˚ • Medium-to-high feed W insert f ≈ [mm/rev] Recommended feed range as a function of insert width 18 Feed mm/rev 0.80 High Alloy Austenitic Temp. Nonferrous Cast Steel Stainless Alloys Materials Iron 0.45 ✔ ✘ ✔ ✔ ✔ 0.35 (IC20 only) (IC20 only) 0.25 0.15 Recommendations are for neutral inserts. 0.02 Width For R/L inserts, reduce feed by 20-40%. 1.6 2.0 3.0 4.0 5.0 6.0 8.0 9.0 12.7 mm MF Type • Parting and Grooving Double-Sided Insert for Soft and Hard Materials, Medium Feed 12° W insert f ≈ [mm/rev] 21 Alloy Austenitic High Temp. Nonferrous Cast Steel Stainless Alloys Materials Iron ✔ ✔ ✔ ✘ ✔ JT-Type The JT chipformer design is based on the J-type 5° chipformer with a T-land reinforced frontal cutting edge. • Provides a solution for the intermediate range between the strong and negative C-type configuration and the positive edged J-type chipformer. 7° • Can be used on a wide range of materials, including soft or hard alloy and stainless steel, Recommended feed range as a function of insert width high temperature alloys and also cast iron. • The JT chipformer deforms the chips into compact Feed mm/rev shapes, in the same manner as the J-type, but it can 0.30 be used at higher feeds due to its reinforced edge. W insert 0.25 f ≈ [mm/rev] 24 0.20 High Alloy Austenitic Temp. Nonferrous Cast 0.15 Steel Stainless Alloys Materials Iron ✔ ✔ ✔ ✘ ✔ 0.10 Width 2 3 4 5 6 7 mm 366 366 ISCAR ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017