Каталог Iscar токарный инструмент 2017 - страница 366

Навигация

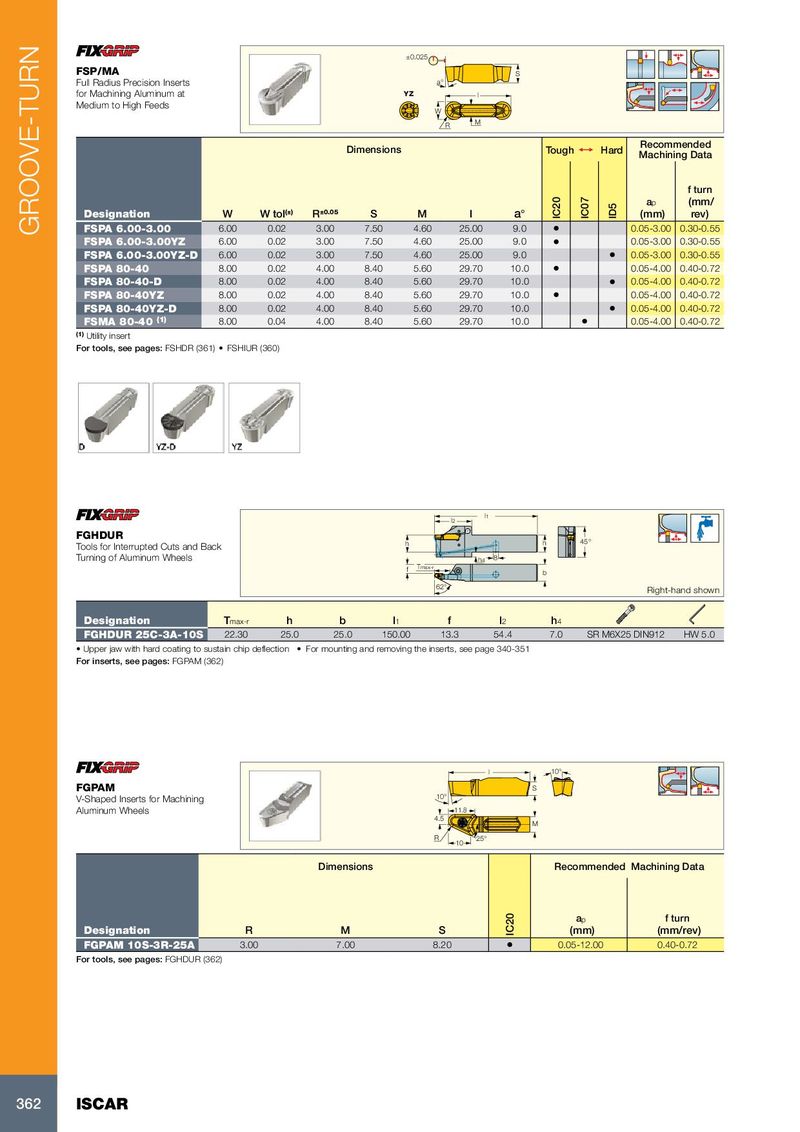

±0.025 FSP/MA S Full Radius Precision Inserts a° for Machining Aluminum at YZ l Medium to High Feeds W R M Recommended Dimensions Tough 1 Hard Machining Data f turn a p (mm/ Designation W W tol (±) R ±0.05 S M l a° IC20 IC07 ID5 (mm) rev) GROOVE-TURN FSPA 6.00-3.00 6.00 0.02 3.00 7.50 4.60 25.00 9.0 • 0.05-3.00 0.30-0.55 FSPA 6.00-3.00YZ 6.00 0.02 3.00 7.50 4.60 25.00 9.0 • 0.05-3.00 0.30-0.55 FSPA 6.00-3.00YZ-D 6.00 0.02 3.00 7.50 4.60 25.00 9.0 • 0.05-3.00 0.30-0.55 FSPA 80-40 8.00 0.02 4.00 8.40 5.60 29.70 10.0 • 0.05-4.00 0.40-0.72 FSPA 80-40-D 8.00 0.02 4.00 8.40 5.60 29.70 10.0 • 0.05-4.00 0.40-0.72 FSPA 80-40YZ 8.00 0.02 4.00 8.40 5.60 29.70 10.0 • 0.05-4.00 0.40-0.72 FSPA 80-40YZ-D 8.00 0.02 4.00 8.40 5.60 29.70 10.0 • 0.05-4.00 0.40-0.72 FSMA 80-40 (1) 8.00 0.04 4.00 8.40 5.60 29.70 10.0 • 0.05-4.00 0.40-0.72 (1) Utility insert For tools, see pages: FSHDR (361) • FSHIUR (360) l1 l2 FGHDUR Tools for Interrupted Cuts and Back h h 45° Turning of Aluminum Wheels h 4 8 f Tmax-r b 62° Right-hand shown Designation T max-r h b l 1 f l 2 h 4 FGHDUR 25C-3A-10S 22.30 25.0 25.0 150.00 13.3 54.4 7.0 SR M6X25 DIN912 HW 5.0 • Upper jaw with hard coating to sustain chip deflection • For mounting and removing the inserts, see page 340-351 For inserts, see pages: FGPAM (362) 10° l FGPAM S V-Shaped Inserts for Machining 10° Aluminum Wheels 11.8 4.5 M R 25° 10 Dimensions Recommended Machining Data a p f turn Designation R M S IC20 (mm) (mm/rev) FGPAM 10S-3R-25A 3.00 7.00 8.20 • 0.05-12.00 0.40-0.72 For tools, see pages: FGHDUR (362) 362 ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017