Каталог Iscar токарный инструмент 2017 - страница 364

Навигация

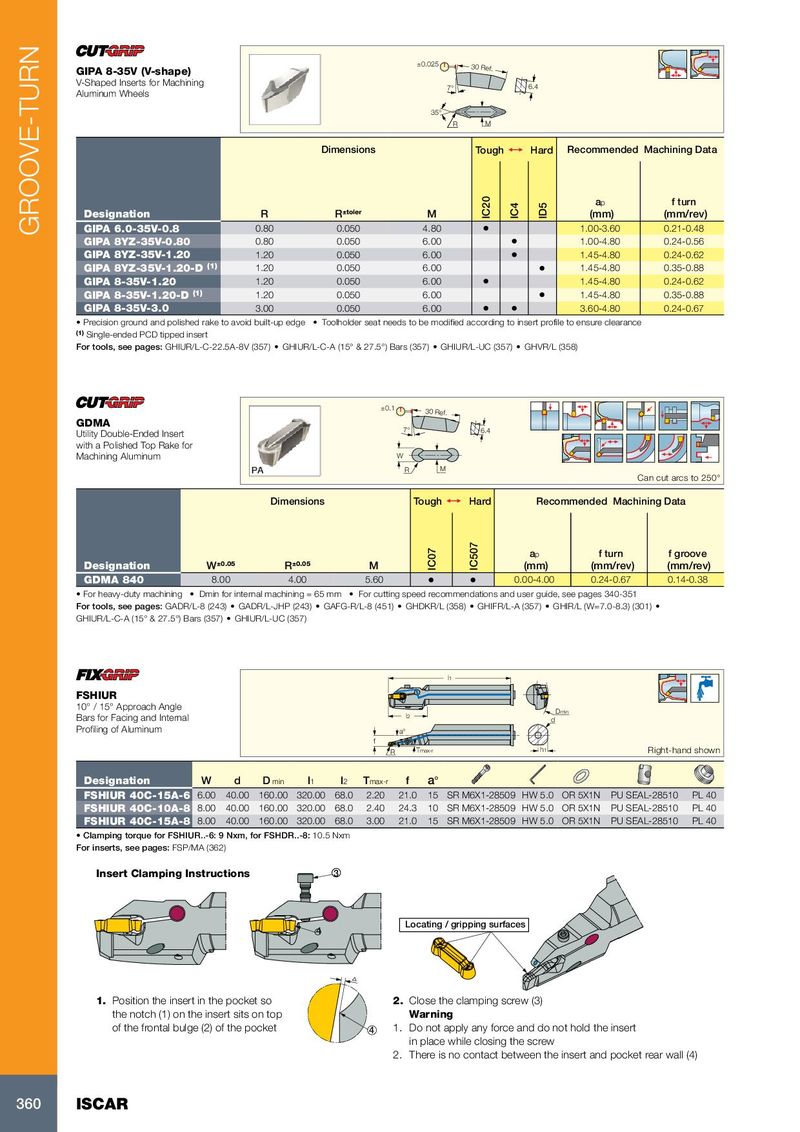

±0.025 30 Ref. GIPA 8-35V (V-shape) V-Shaped Inserts for Machining 7° 6.4 Aluminum Wheels 35° R M Dimensions Tough 1 Hard Recommended Machining Data a p f turn Designation R R ±toler M IC20 IC4 ID5 (mm) (mm/rev) GROOVE-TURN GIPA 6.0-35V-0.8 0.80 0.050 4.80 • 1.00-3.60 0.21-0.48 GIPA 8YZ-35V-0.80 0.80 0.050 6.00 • 1.00-4.80 0.24-0.56 GIPA 8YZ-35V-1.20 1.20 0.050 6.00 • 1.45-4.80 0.24-0.62 GIPA 8YZ-35V-1.20-D (1) 1.20 0.050 6.00 • 1.45-4.80 0.35-0.88 GIPA 8-35V-1.20 1.20 0.050 6.00 • 1.45-4.80 0.24-0.62 GIPA 8-35V-1.20-D (1) 1.20 0.050 6.00 • 1.45-4.80 0.35-0.88 GIPA 8-35V-3.0 3.00 0.050 6.00 • • 3.60-4.80 0.24-0.67 • Precision ground and polished rake to avoid built-up edge • Toolholder seat needs to be modified according to insert profile to ensure clearance (1) Single-ended PCD tipped insert For tools, see pages: GHIUR/L-C-22.5A-8V (357) • GHIUR/L-C-A (15° & 27.5°) Bars (357) • GHIUR/L-UC (357) • GHVR/L (358) ±0.1 30 Ref. GDMA 7° 6.4 Utility Double-Ended Insert with a Polished Top Rake for Machining Aluminum W R M Can cut arcs to 250° Dimensions Tough 1 Hard Recommended Machining Data a p f turn f groove Designation W ±0.05 R ±0.05 M IC07 IC507 (mm) (mm/rev) (mm/rev) GDMA 840 8.00 4.00 5.60 • • 0.00-4.00 0.24-0.67 0.14-0.38 • For heavy-duty machining • Dmin for internal machining = 65 mm • For cutting speed recommendations and user guide, see pages 340-351 For tools, see pages: GADR/L-8 (243) • GADR/L-JHP (243) • GAFG-R/L-8 (451) • GHDKR/L (358) • GHIFR/L-A (357) • GHIR/L (W=7.0-8.3) (301) • GHIUR/L-C-A (15° & 27.5°) Bars (357) • GHIUR/L-UC (357) l1 FSHIUR 10° / 15° Approach Angle Dmin Bars for Facing and Internal l2 d Profiling of Aluminum a° f R Tmax-r h1 Right-hand shown Designation W d D min l 1 l 2 T max-r f a° FSHIUR 40C-15A-6 6.00 40.00 160.00 320.00 68.0 2.20 21.0 15 SR M6X1-28509 HW 5.0 OR 5X1N PU SEAL-28510 PL 40 FSHIUR 40C-10A-8 8.00 40.00 160.00 320.00 68.0 2.40 24.3 10 SR M6X1-28509 HW 5.0 OR 5X1N PU SEAL-28510 PL 40 FSHIUR 40C-15A-8 8.00 40.00 160.00 320.00 68.0 3.00 21.0 15 SR M6X1-28509 HW 5.0 OR 5X1N PU SEAL-28510 PL 40 • Clamping torque for FSHIUR..-6: 9 Nxm, for FSHDR..-8: 10.5 Nxm For inserts, see pages: FSP/MA (362) Insert Clamping Instructions 3 Locating / gripping surfaces 4 1. Position the insert in the pocket so 2. Close the clamping screw (3) the notch (1) on the insert sits on top Warning of the frontal bulge (2) of the pocket 4 1. Do not apply any force and do not hold the insert in place while closing the screw 2. There is no contact between the insert and pocket rear wall (4) 360 ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017