Каталог Iscar токарный инструмент 2017 - страница 358

Навигация

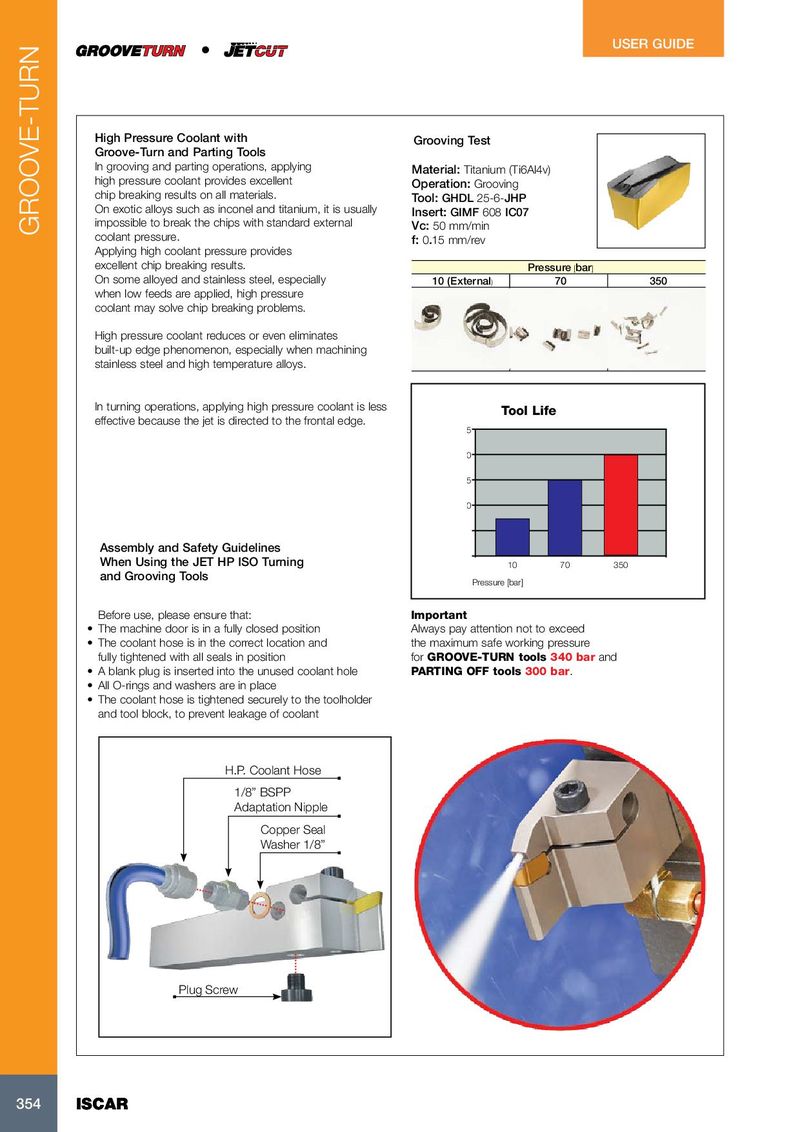

USER GUIDE • High Pressure Coolant with Grooving Test Groove-Turn and Parting Tools In grooving and parting operations, applying Material: Titanium (Ti6Al4v) high pressure coolant provides excellent Operation: Grooving chip breaking results on all materials. Tool: GHDL 25-6-JHP On exotic alloys such as inconel and titanium, it is usually Insert: GIMF 608 IC07 impossible to break the chips with standard external Vc: 50 mm/min GROOVE-TURN coolant pressure. f: 0.15 mm/rev Applying high coolant pressure provides excellent chip breaking results. Pressure [ bar ] On some alloyed and stainless steel, especially 10 (External ) 70 350 when low feeds are applied, high pressure coolant may solve chip breaking problems. High pressure coolant reduces or even eliminates built-up edge phenomenon, especially when machining stainless steel and high temperature alloys. In turning operations, applying high pressure coolant is less Tool Life effective because the jet is directed to the frontal edge. 25 20 15 10 Grooves 5 Assembly and Safety Guidelines 0 When Using the JET HP ISO Turning 10 70 350 and Grooving Tools Pressure [bar] Before use, please ensure that: Important • The machine door is in a fully closed position Always pay attention not to exceed • The coolant hose is in the correct location and the maximum safe working pressure fully tightened with all seals in position for GROOVE-TURN tools 340 bar and • A blank plug is inserted into the unused coolant hole PARTING OFF tools 300 bar. • All O-rings and washers are in place • The coolant hose is tightened securely to the toolholder and tool block, to prevent leakage of coolant H.P. Coolant Hose 1/8” BSPP Adaptation Nipple Copper Seal Washer 1/8” Plug Screw 354 354 ISCAR ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017