Каталог Iscar токарный инструмент 2017 - страница 356

Навигация

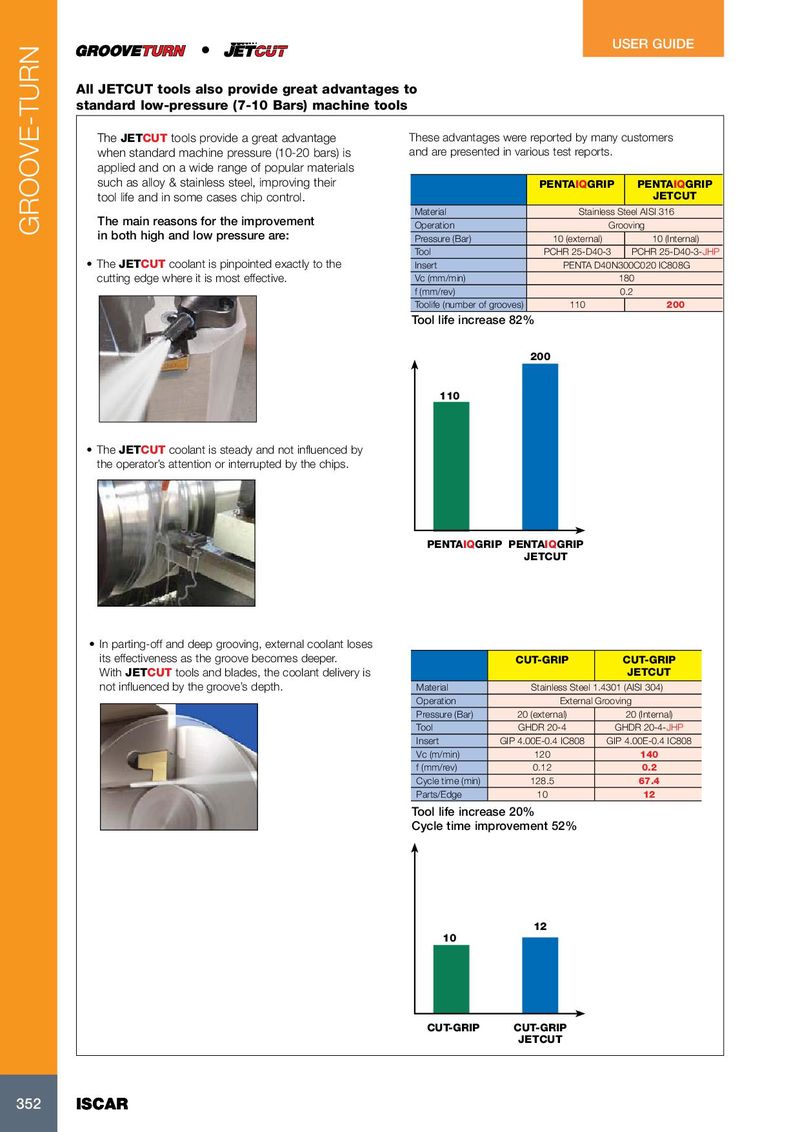

USER GUIDE • All JETCUT tools also provide great advantages to standard low-pressure (7-10 Bars) machine tools The JETCUT tools provide a great advantage These advantages were reported by many customers when standard machine pressure (10-20 bars) is and are presented in various test reports. applied and on a wide range of popular materials such as alloy & stainless steel, improving their PENTAIQGRIP PENTAIQGRIP tool life and in some cases chip control. JETCUT Material Stainless Steel AISI 316 The main reasons for the improvement Operation Grooving GROOVE-TURN in both high and low pressure are: Pressure (Bar) 10 (external) 10 (Internal) Tool PCHR 25-D40-3 PCHR 25-D40-3-JHP • The JETCUT coolant is pinpointed exactly to the Insert PENTA D40N300C020 IC808G cutting edge where it is most effective. Vc (mm/min) 180 f (mm/rev) 0.2 Toolife (number of grooves) 110 200 Tool life increase 82% 200 110 • The JETCUT coolant is steady and not influenced by the operator’s attention or interrupted by the chips. PENTAIQGRIP PENTAIQGRIP JETCUT • In parting-off and deep grooving, external coolant loses its effectiveness as the groove becomes deeper. CUT-GRIP CUT-GRIP With JETCUT tools and blades, the coolant delivery is JETCUT not influenced by the groove’s depth. Material Stainless Steel 1.4301 (AISI 304) Operation External Grooving Pressure (Bar) 20 (external) 20 (Internal) Tool GHDR 20-4 GHDR 20-4-JHP Insert GIP 4.00E-0.4 IC808 GIP 4.00E-0.4 IC808 Vc (m/min) 120 140 f (mm/rev) 0.12 0.2 Cycle time (min) 128.5 67.4 Parts/Edge 10 12 Tool life increase 20% Cycle time improvement 52% 12 10 CUT-GRIP CUT-GRIP JETCUT 352 352 ISCAR ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017