Каталог Iscar токарный инструмент 2017 - страница 342

Навигация

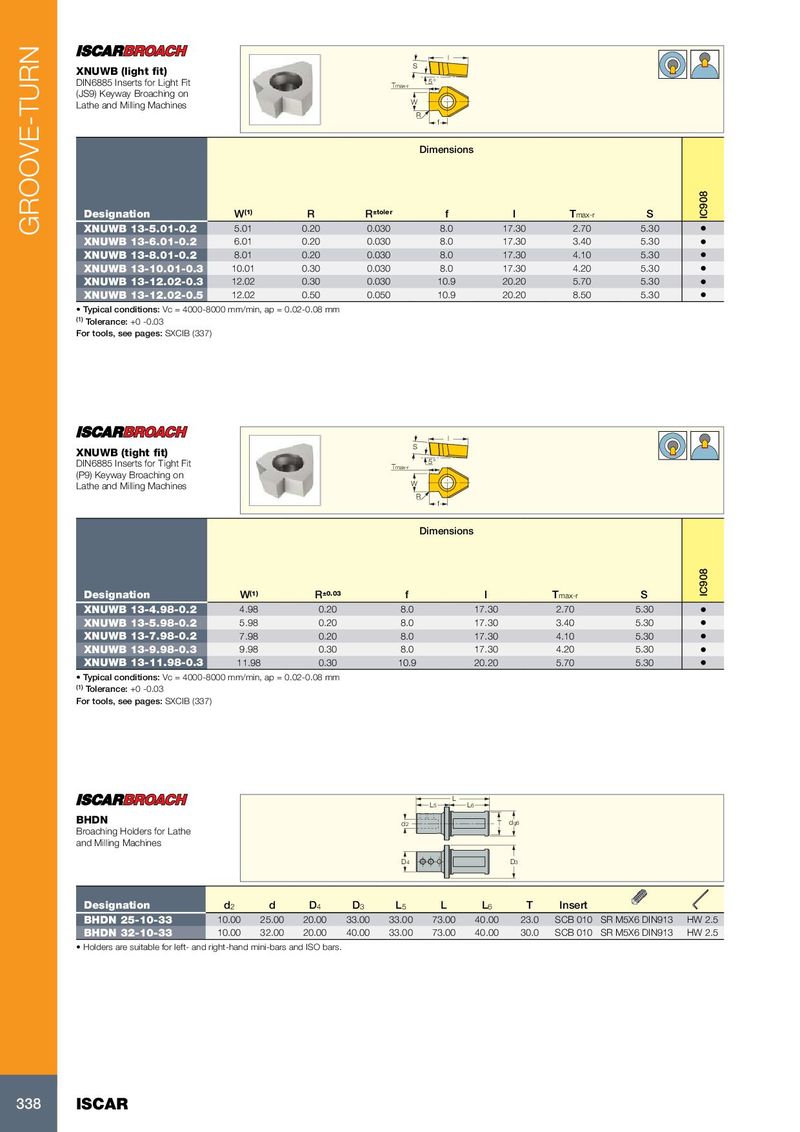

l S XNUWB (light fit) DIN6885 Inserts for Light Fit 5° Tmax-r (JS9) Keyway Broaching on Lathe and Milling Machines W R f Dimensions Designation W (1) R R ±toler f l T max-r S IC908 GROOVE-TURN XNUWB 13-5.01-0.2 5.01 0.20 0.030 8.0 17.30 2.70 5.30 • XNUWB 13-6.01-0.2 6.01 0.20 0.030 8.0 17.30 3.40 5.30 • XNUWB 13-8.01-0.2 8.01 0.20 0.030 8.0 17.30 4.10 5.30 • XNUWB 13-10.01-0.3 10.01 0.30 0.030 8.0 17.30 4.20 5.30 • XNUWB 13-12.02-0.3 12.02 0.30 0.030 10.9 20.20 5.70 5.30 • XNUWB 13-12.02-0.5 12.02 0.50 0.050 10.9 20.20 8.50 5.30 • • Typical conditions: Vc = 4000-8000 mm/min, ap = 0.02-0.08 mm (1) Tolerance: +0 -0.03 For tools, see pages: SXCIB (337) l S XNUWB (tight fit) DIN6885 Inserts for Tight Fit 5° Tmax-r (P9) Keyway Broaching on Lathe and Milling Machines W R f Dimensions Designation W (1) R ±0.03 f l T max-r S IC908 XNUWB 13-4.98-0.2 4.98 0.20 8.0 17.30 2.70 5.30 • XNUWB 13-5.98-0.2 5.98 0.20 8.0 17.30 3.40 5.30 • XNUWB 13-7.98-0.2 7.98 0.20 8.0 17.30 4.10 5.30 • XNUWB 13-9.98-0.3 9.98 0.30 8.0 17.30 4.20 5.30 • XNUWB 13-11.98-0.3 11.98 0.30 10.9 20.20 5.70 5.30 • • Typical conditions: Vc = 4000-8000 mm/min, ap = 0.02-0.08 mm (1) Tolerance: +0 -0.03 For tools, see pages: SXCIB (337) L L5 L6 BHDN d2 T dg6 Broaching Holders for Lathe and Milling Machines D4 D3 Designation d 2 d D 4 D 3 L 5 L L 6 T Insert BHDN 25-10-33 10.00 25.00 20.00 33.00 33.00 73.00 40.00 23.0 SCB 010 SR M5X6 DIN913 HW 2.5 BHDN 32-10-33 10.00 32.00 20.00 40.00 33.00 73.00 40.00 30.0 SCB 010 SR M5X6 DIN913 HW 2.5 • Holders are suitable for left- and right-hand mini-bars and ISO bars. 338 ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017