Каталог Iscar токарный инструмент 2017 - страница 275

Навигация

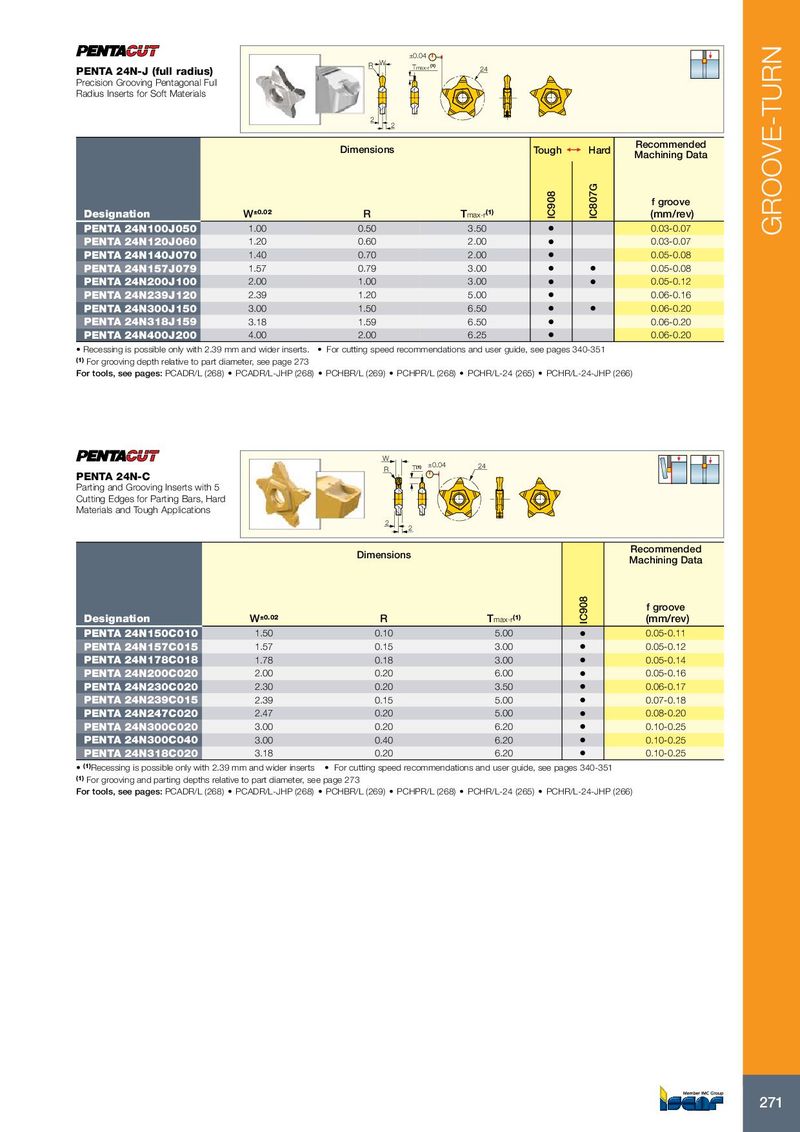

±0.04 R W Tmax-r (1) PENTA 24N-J (full radius) 24 Precision Grooving Pentagonal Full Radius Inserts for Soft Materials 2 2 Recommended Dimensions Tough 1 Hard Machining Data f groove Designation W ±0.02 R T max-r (1) IC908 IC807G (mm/rev) PENTA 24N100J050 1.00 0.50 3.50 • 0.03-0.07 GROOVE-TURN PENTA 24N120J060 1.20 0.60 2.00 • 0.03-0.07 PENTA 24N140J070 1.40 0.70 2.00 • 0.05-0.08 PENTA 24N157J079 1.57 0.79 3.00 • • 0.05-0.08 PENTA 24N200J100 2.00 1.00 3.00 • • 0.05-0.12 PENTA 24N239J120 2.39 1.20 5.00 • 0.06-0.16 PENTA 24N300J150 3.00 1.50 6.50 • • 0.06-0.20 PENTA 24N318J159 3.18 1.59 6.50 • 0.06-0.20 PENTA 24N400J200 4.00 2.00 6.25 • 0.06-0.20 • Recessing is possible only with 2.39 mm and wider inserts. • For cutting speed recommendations and user guide, see pages 340-351 (1) For grooving depth relative to part diameter, see page 273 For tools, see pages: PCADR/L (268) • PCADR/L-JHP (268) • PCHBR/L (269) • PCHPR/L (268) • PCHR/L-24 (265) • PCHR/L-24-JHP (266) W R T (1) ±0.04 24 PENTA 24N-C Parting and Grooving Inserts with 5 Cutting Edges for Parting Bars, Hard Materials and Tough Applications 2 2 Recommended Dimensions Machining Data f groove Designation W ±0.02 R T max-r (1) IC908 (mm/rev) PENTA 24N150C010 1.50 0.10 5.00 • 0.05-0.11 PENTA 24N157C015 1.57 0.15 3.00 • 0.05-0.12 PENTA 24N178C018 1.78 0.18 3.00 • 0.05-0.14 PENTA 24N200C020 2.00 0.20 6.00 • 0.05-0.16 PENTA 24N230C020 2.30 0.20 3.50 • 0.06-0.17 PENTA 24N239C015 2.39 0.15 5.00 • 0.07-0.18 PENTA 24N247C020 2.47 0.20 5.00 • 0.08-0.20 PENTA 24N300C020 3.00 0.20 6.20 • 0.10-0.25 PENTA 24N300C040 3.00 0.40 6.20 • 0.10-0.25 PENTA 24N318C020 3.18 0.20 6.20 • 0.10-0.25 • (1) Recessing is possible only with 2.39 mm and wider inserts • For cutting speed recommendations and user guide, see pages 340-351 (1) For grooving and parting depths relative to part diameter, see page 273 For tools, see pages: PCADR/L (268) • PCADR/L-JHP (268) • PCHBR/L (269) • PCHPR/L (268) • PCHR/L-24 (265) • PCHR/L-24-JHP (266) 271

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017