Каталог Iscar токарный инструмент 2017 - страница 203

Навигация

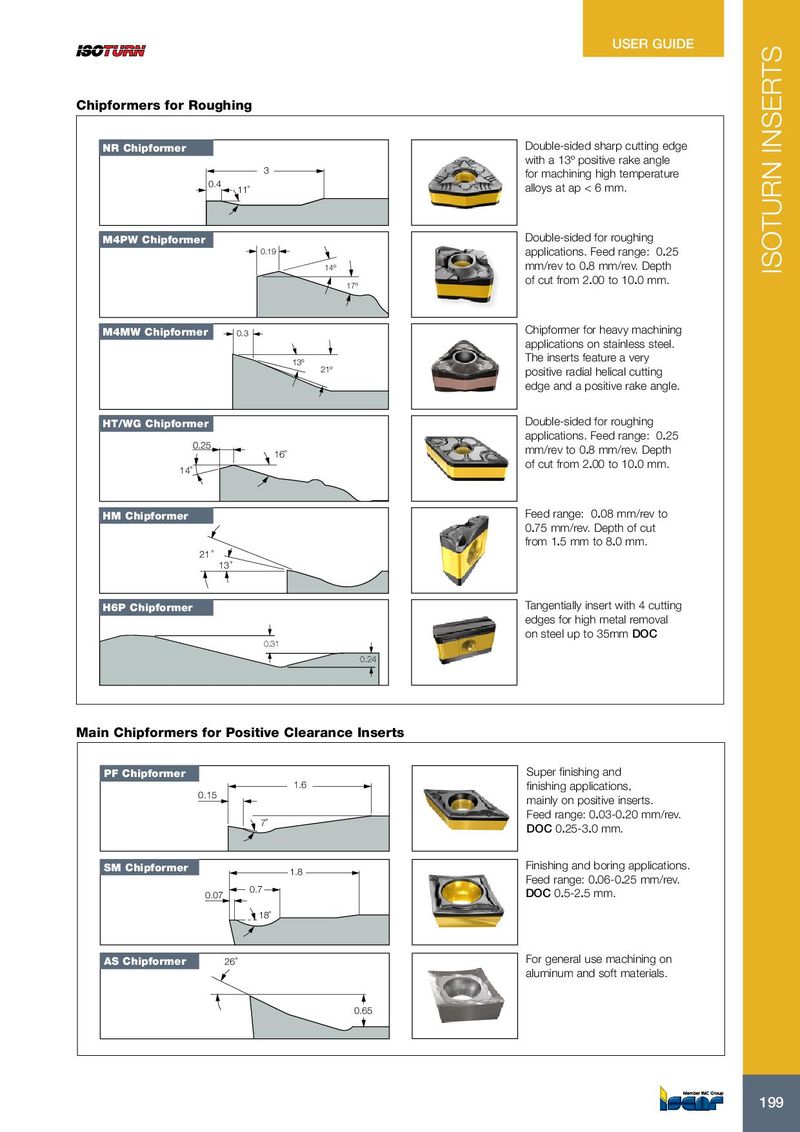

USER GUIDE Chipformers for Roughing NR Chipformer Double-sided sharp cutting edge with a 13º positive rake angle 3 for machining high temperature 0.4 11˚ alloys at ap < 6 mm. M4PW Chipformer Double-sided for roughing 0.19 applications. Feed range: 0.25 14º mm/rev to 0.8 mm/rev. Depth ISOTURN INSERTS of cut from 2.00 to 10.0 mm. 17º M4MW Chipformer 0.3 Chipformer for heavy machining applications on stainless steel. 13º The inserts feature a very 21º positive radial helical cutting edge and a positive rake angle. HT/WG Chipformer Double-sided for roughing applications. Feed range: 0.25 0.25 mm/rev to 0.8 mm/rev. Depth 16˚ of cut from 2.00 to 10.0 mm. 14˚ HM Chipformer Feed range: 0.08 mm/rev to 0.75 mm/rev. Depth of cut from 1.5 mm to 8.0 mm. 21 ˚ 13 ˚ H6P Chipformer Tangentially insert with 4 cutting edges for high metal removal on steel up to 35mm DOC 0.31 0.24 Main Chipformers for Positive Clearance Inserts PF Chipformer Super finishing and 1.6 finishing applications, 0.15 mainly on positive inserts. Feed range: 0.03-0.20 mm/rev. 7˚ DOC 0.25-3.0 mm. SM Chipformer Finishing and boring applications. 1.8 Feed range: 0.06-0.25 mm/rev. 0.7 0.07 DOC 0.5-2.5 mm. 18˚ AS Chipformer 26˚ For general use machining on aluminum and soft materials. 0.65 199 199

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017