Каталог Iscar токарный инструмент 2017 - страница 195

Навигация

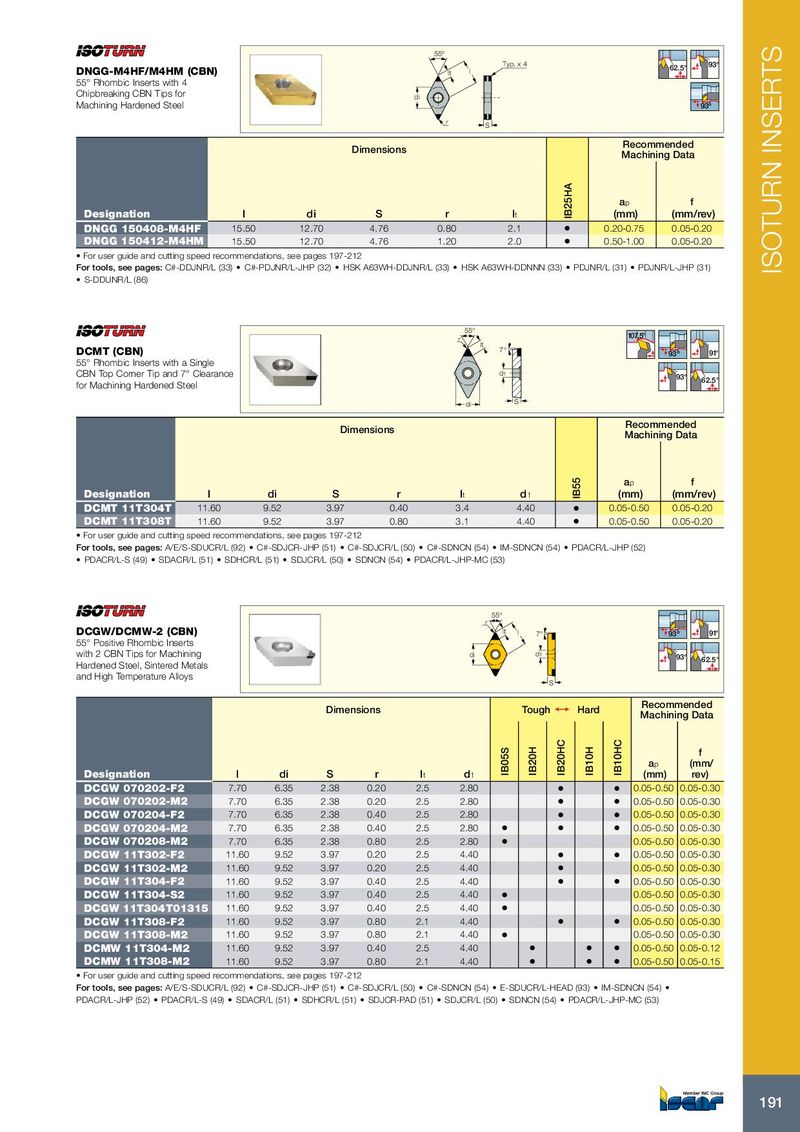

55º Typ. x 4 62.5° 93° DNGG-M4HF/M4HM (CBN) lt l 55° Rhombic Inserts with 4 Chipbreaking CBN Tips for di Machining Hardened Steel 93º r S Recommended Dimensions Machining Data a p f Designation l di S r l t IB25HA (mm) (mm/rev) DNGG 150408-M4HF 15.50 12.70 4.76 0.80 2.1 • 0.20-0.75 0.05-0.20 DNGG 150412-M4HM 15.50 12.70 4.76 1.20 2.0 • 0.50-1.00 0.05-0.20 • For user guide and cutting speed recommendations, see pages 197-212 For tools, see pages: C#-DDJNR/L (33) • C#-PDJNR/L-JHP (32) • HSK A63WH-DDJNR/L (33) • HSK A63WH-DDNNN (33) • PDJNR/L (31) • PDJNR/L-JHP (31) ISOTURN INSERTS • S-DDUNR/L (86) 55 ° r 107.5° lt DCMT (CBN) 7 ° 93º 91° 55° Rhombic Inserts with a Single CBN Top Corner Tip and 7° Clearance d1 93° 62.5° for Machining Hardened Steel di S Recommended Dimensions Machining Data a p f Designation l di S r l t d 1 IB55 (mm) (mm/rev) DCMT 11T304T 11.60 9.52 3.97 0.40 3.4 4.40 • 0.05-0.50 0.05-0.20 DCMT 11T308T 11.60 9.52 3.97 0.80 3.1 4.40 • 0.05-0.50 0.05-0.20 • For user guide and cutting speed recommendations, see pages 197-212 For tools, see pages: A/E/S-SDUCR/L (92) • C#-SDJCR-JHP (51) • C#-SDJCR/L (50) • C#-SDNCN (54) • IM-SDNCN (54) • PDACR/L-JHP (52) • PDACR/L-S (49) • SDACR/L (51) • SDHCR/L (51) • SDJCR/L (50) • SDNCN (54) • PDACR/L-JHP-MC (53) 55 ° r DCGW/DCMW-2 (CBN) lt l 7 ° 93º 91° 55° Positive Rhombic Inserts with 2 CBN Tips for Machining di d1 93° 62.5° Hardened Steel, Sintered Metals and High Temperature Alloys S Recommended Dimensions Tough 1 Hard Machining Data f a p (mm/ Designation l di S r l t d 1 IB05S IB20H IB20HC IB10H IB10HC (mm) rev) DCGW 070202-F2 7.70 6.35 2.38 0.20 2.5 2.80 • • 0.05-0.50 0.05-0.30 DCGW 070202-M2 7.70 6.35 2.38 0.20 2.5 2.80 • • 0.05-0.50 0.05-0.30 DCGW 070204-F2 7.70 6.35 2.38 0.40 2.5 2.80 • • 0.05-0.50 0.05-0.30 DCGW 070204-M2 7.70 6.35 2.38 0.40 2.5 2.80 • • • 0.05-0.50 0.05-0.30 DCGW 070208-M2 7.70 6.35 2.38 0.80 2.5 2.80 • 0.05-0.50 0.05-0.30 DCGW 11T302-F2 11.60 9.52 3.97 0.20 2.5 4.40 • • 0.05-0.50 0.05-0.30 DCGW 11T302-M2 11.60 9.52 3.97 0.20 2.5 4.40 • 0.05-0.50 0.05-0.30 DCGW 11T304-F2 11.60 9.52 3.97 0.40 2.5 4.40 • • 0.05-0.50 0.05-0.30 DCGW 11T304-S2 11.60 9.52 3.97 0.40 2.5 4.40 • 0.05-0.50 0.05-0.30 DCGW 11T304T01315 11.60 9.52 3.97 0.40 2.5 4.40 • 0.05-0.50 0.05-0.30 DCGW 11T308-F2 11.60 9.52 3.97 0.80 2.1 4.40 • • 0.05-0.50 0.05-0.30 DCGW 11T308-M2 11.60 9.52 3.97 0.80 2.1 4.40 • 0.05-0.50 0.05-0.30 DCMW 11T304-M2 11.60 9.52 3.97 0.40 2.5 4.40 • • • 0.05-0.50 0.05-0.12 DCMW 11T308-M2 11.60 9.52 3.97 0.80 2.1 4.40 • • • 0.05-0.50 0.05-0.15 • For user guide and cutting speed recommendations, see pages 197-212 For tools, see pages: A/E/S-SDUCR/L (92) • C#-SDJCR-JHP (51) • C#-SDJCR/L (50) • C#-SDNCN (54) • E-SDUCR/L-HEAD (93) • IM-SDNCN (54) • PDACR/L-JHP (52) • PDACR/L-S (49) • SDACR/L (51) • SDHCR/L (51) • SDJCR-PAD (51) • SDJCR/L (50) • SDNCN (54) • PDACR/L-JHP-MC (53) 191

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017