Каталог Iscar токарный инструмент 2017 - страница 191

Навигация

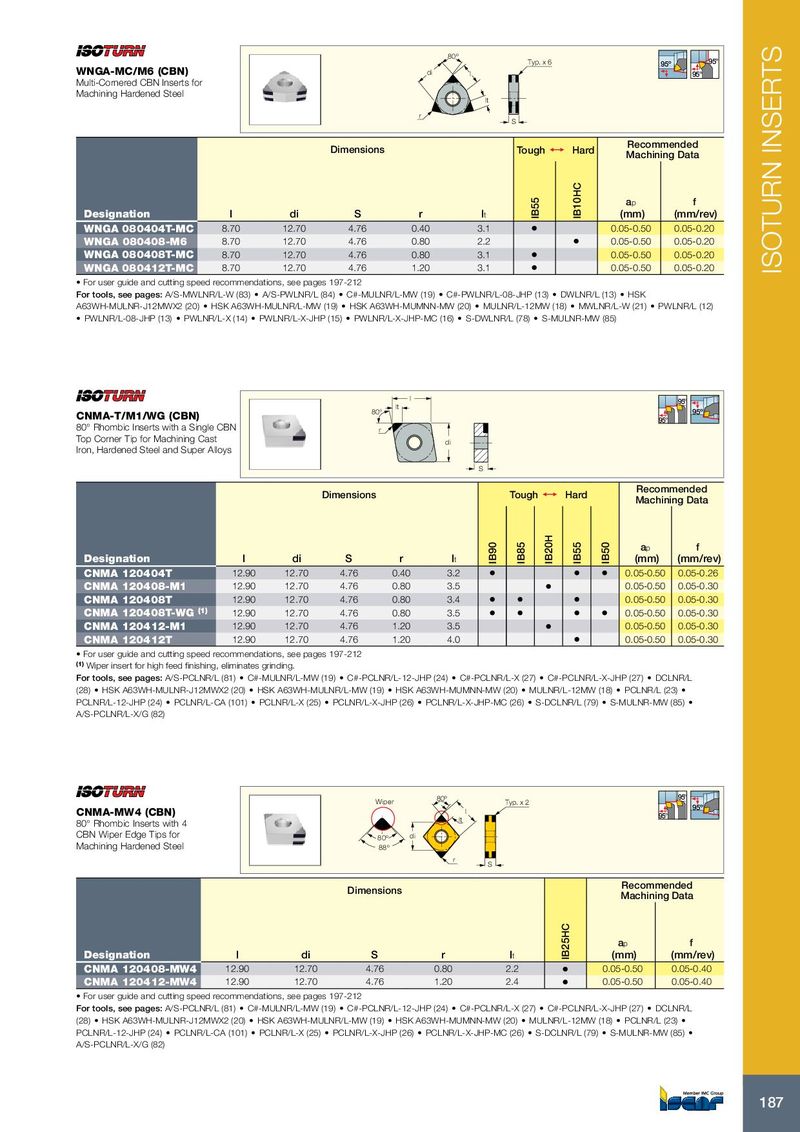

80º Typ. x 6 95º 95° WNGA-MC/M6 (CBN) di l 95° Multi-Cornered CBN Inserts for Machining Hardened Steel lt r S Recommended Dimensions Tough 1 Hard Machining Data a p f Designation l di S r l t IB55 IB10HC (mm) (mm/rev) WNGA 080404T-MC 8.70 12.70 4.76 0.40 3.1 • 0.05-0.50 0.05-0.20 WNGA 080408-M6 8.70 12.70 4.76 0.80 2.2 • 0.05-0.50 0.05-0.20 WNGA 080408T-MC 8.70 12.70 4.76 0.80 3.1 • 0.05-0.50 0.05-0.20 WNGA 080412T-MC 8.70 12.70 4.76 1.20 3.1 • 0.05-0.50 0.05-0.20 ISOTURN INSERTS • For user guide and cutting speed recommendations, see pages 197-212 For tools, see pages: A/S-MWLNR/L-W (83) • A/S-PWLNR/L (84) • C#-MULNR/L-MW (19) • C#-PWLNR/L-08-JHP (13) • DWLNR/L (13) • HSK A63WH-MULNR-J12MWX2 (20) • HSK A63WH-MULNR/L-MW (19) • HSK A63WH-MUMNN-MW (20) • MULNR/L-12MW (18) • MWLNR/L-W (21) • PWLNR/L (12) • PWLNR/L-08-JHP (13) • PWLNR/L-X (14) • PWLNR/L-X-JHP (15) • PWLNR/L-X-JHP-MC (16) • S-DWLNR/L (78) • S-MULNR-MW (85) l 95° lt 80 ° 95º CNMA-T/M1/WG (CBN) 95° 80° Rhombic Inserts with a Single CBN r Top Corner Tip for Machining Cast di Iron, Hardened Steel and Super Alloys S Recommended Dimensions Tough 1 Hard Machining Data a p f Designation l di S r l t IB90 IB85 IB20H IB55 IB50 (mm) (mm/rev) CNMA 120404T 12.90 12.70 4.76 0.40 3.2 • • • 0.05-0.50 0.05-0.26 CNMA 120408-M1 12.90 12.70 4.76 0.80 3.5 • 0.05-0.50 0.05-0.30 CNMA 120408T 12.90 12.70 4.76 0.80 3.4 • • • 0.05-0.50 0.05-0.30 CNMA 120408T-WG (1) 12.90 12.70 4.76 0.80 3.5 • • • • 0.05-0.50 0.05-0.30 CNMA 120412-M1 12.90 12.70 4.76 1.20 3.5 • 0.05-0.50 0.05-0.30 CNMA 120412T 12.90 12.70 4.76 1.20 4.0 • 0.05-0.50 0.05-0.30 • For user guide and cutting speed recommendations, see pages 197-212 (1) Wiper insert for high feed finishing, eliminates grinding. For tools, see pages: A/S-PCLNR/L (81) • C#-MULNR/L-MW (19) • C#-PCLNR/L-12-JHP (24) • C#-PCLNR/L-X (27) • C#-PCLNR/L-X-JHP (27) • DCLNR/L (28) • HSK A63WH-MULNR-J12MWX2 (20) • HSK A63WH-MULNR/L-MW (19) • HSK A63WH-MUMNN-MW (20) • MULNR/L-12MW (18) • PCLNR/L (23) • PCLNR/L-12-JHP (24) • PCLNR/L-CA (101) • PCLNR/L-X (25) • PCLNR/L-X-JHP (26) • PCLNR/L-X-JHP-MC (26) • S-DCLNR/L (79) • S-MULNR-MW (85) • A/S-PCLNR/L-X/G (82) 95° Wiper 80º Typ. x 2 95º CNMA-MW4 (CBN) l lt 95° 80° Rhombic Inserts with 4 CBN Wiper Edge Tips for 80º di Machining Hardened Steel 88º r S Recommended Dimensions Machining Data a p f Designation l di S r l t IB25HC (mm) (mm/rev) CNMA 120408-MW4 12.90 12.70 4.76 0.80 2.2 • 0.05-0.50 0.05-0.40 CNMA 120412-MW4 12.90 12.70 4.76 1.20 2.4 • 0.05-0.50 0.05-0.40 • For user guide and cutting speed recommendations, see pages 197-212 For tools, see pages: A/S-PCLNR/L (81) • C#-MULNR/L-MW (19) • C#-PCLNR/L-12-JHP (24) • C#-PCLNR/L-X (27) • C#-PCLNR/L-X-JHP (27) • DCLNR/L (28) • HSK A63WH-MULNR-J12MWX2 (20) • HSK A63WH-MULNR/L-MW (19) • HSK A63WH-MUMNN-MW (20) • MULNR/L-12MW (18) • PCLNR/L (23) • PCLNR/L-12-JHP (24) • PCLNR/L-CA (101) • PCLNR/L-X (25) • PCLNR/L-X-JHP (26) • PCLNR/L-X-JHP-MC (26) • S-DCLNR/L (79) • S-MULNR-MW (85) • A/S-PCLNR/L-X/G (82) 187

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017