Каталог Iscar токарный инструмент 2017 - страница 187

Навигация

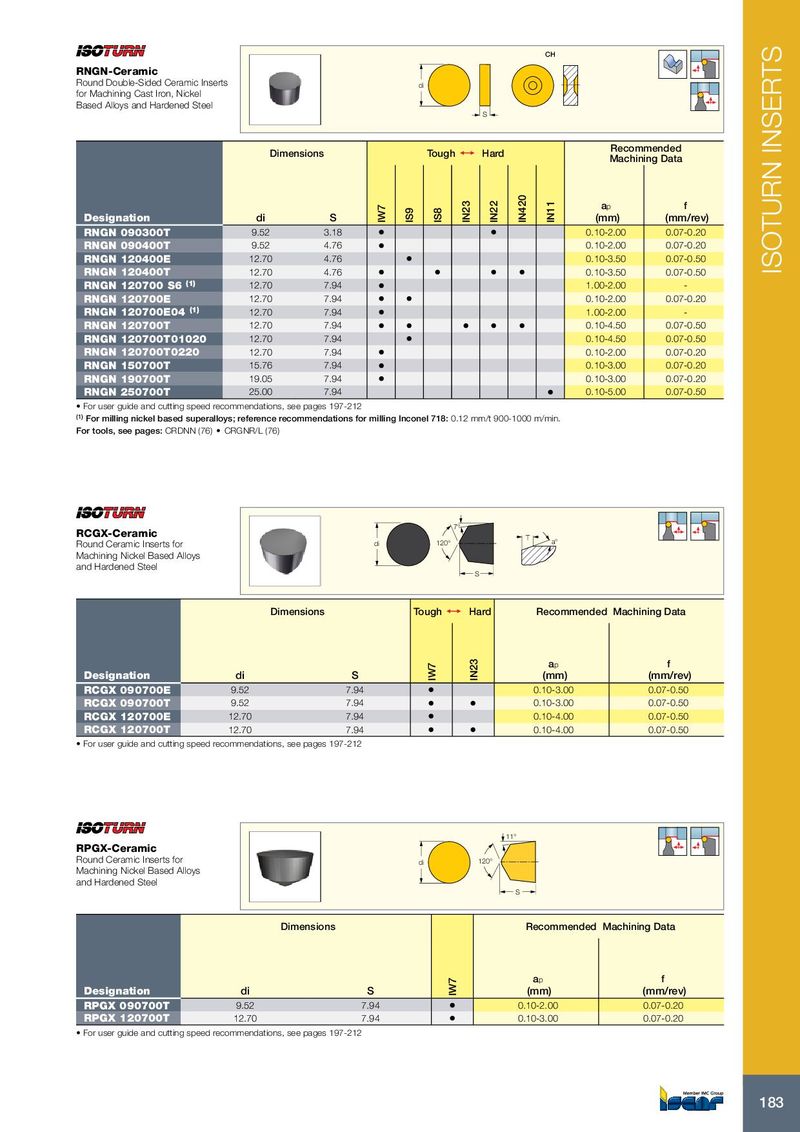

CH RNGN-Ceramic Round Double-Sided Ceramic Inserts di for Machining Cast Iron, Nickel Based Alloys and Hardened Steel S Recommended Dimensions Tough 1 Hard Machining Data a p f Designation di S IW7 IS9 IS8 IN23 IN22 IN420 IN11 (mm) (mm/rev) RNGN 090300T 9.52 3.18 • • 0.10-2.00 0.07-0.20 RNGN 090400T 9.52 4.76 • 0.10-2.00 0.07-0.20 RNGN 120400E 12.70 4.76 • 0.10-3.50 0.07-0.50 RNGN 120400T 12.70 4.76 • • • • 0.10-3.50 0.07-0.50 ISOTURN INSERTS RNGN 120700 S6 (1) 12.70 7.94 • 1.00-2.00 - RNGN 120700E 12.70 7.94 • • 0.10-2.00 0.07-0.20 RNGN 120700E04 (1) 12.70 7.94 • 1.00-2.00 - RNGN 120700T 12.70 7.94 • • • • • 0.10-4.50 0.07-0.50 RNGN 120700T01020 12.70 7.94 • 0.10-4.50 0.07-0.50 RNGN 120700T0220 12.70 7.94 • 0.10-2.00 0.07-0.20 RNGN 150700T 15.76 7.94 • 0.10-3.00 0.07-0.20 RNGN 190700T 19.05 7.94 • 0.10-3.00 0.07-0.20 RNGN 250700T 25.00 7.94 • 0.10-5.00 0.07-0.50 • For user guide and cutting speed recommendations, see pages 197-212 (1) For milling nickel based superalloys; reference recommendations for milling Inconel 718: 0.12 mm/t 900-1000 m/min. For tools, see pages: CRDNN (76) • CRGNR/L (76) 7° RCGX-Ceramic T Round Ceramic Inserts for di 120° a° Machining Nickel Based Alloys and Hardened Steel S Dimensions Tough 1 Hard Recommended Machining Data a p f Designation di S IW7 IN23 (mm) (mm/rev) RCGX 090700E 9.52 7.94 • 0.10-3.00 0.07-0.50 RCGX 090700T 9.52 7.94 • • 0.10-3.00 0.07-0.50 RCGX 120700E 12.70 7.94 • 0.10-4.00 0.07-0.50 RCGX 120700T 12.70 7.94 • • 0.10-4.00 0.07-0.50 • For user guide and cutting speed recommendations, see pages 197-212 11° RPGX-Ceramic Round Ceramic Inserts for di 120° Machining Nickel Based Alloys and Hardened Steel S Dimensions Recommended Machining Data a p f Designation di S IW7 (mm) (mm/rev) RPGX 090700T 9.52 7.94 • 0.10-2.00 0.07-0.20 RPGX 120700T 12.70 7.94 • 0.10-3.00 0.07-0.20 • For user guide and cutting speed recommendations, see pages 197-212 183

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017