Каталог Iscar токарный инструмент 2017 - страница 140

Навигация

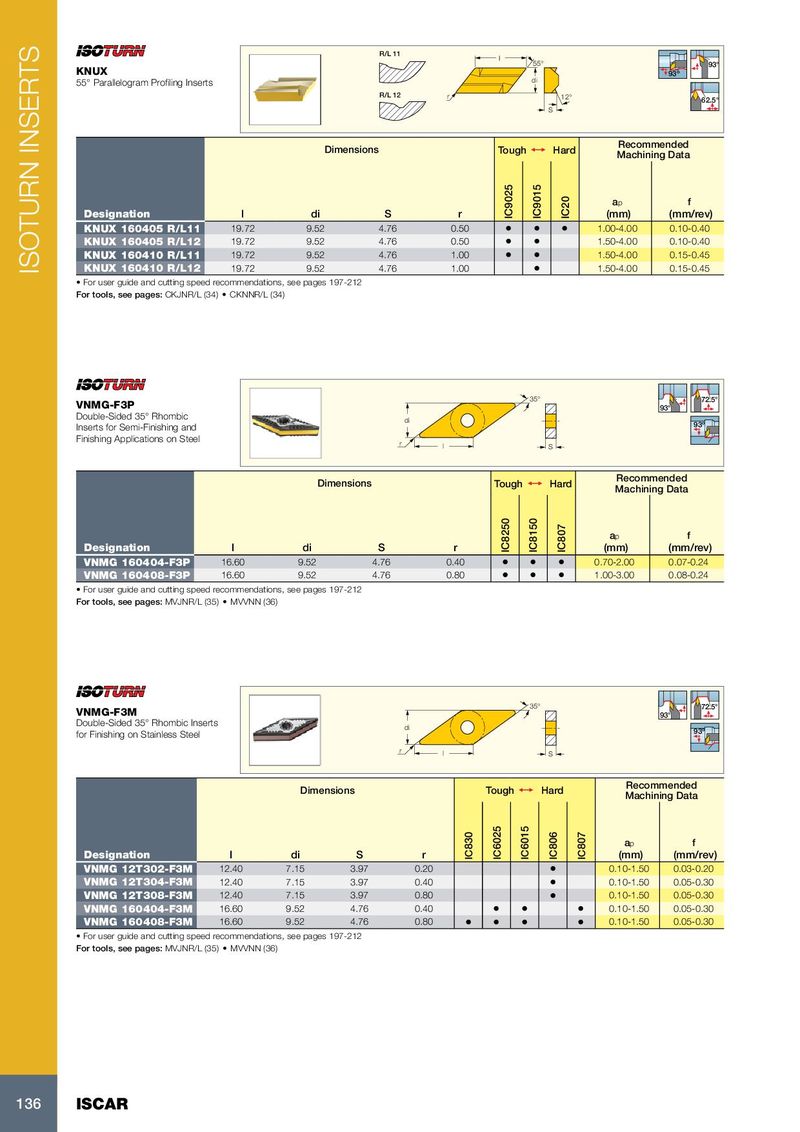

R/L 11 I 55° 93° KNUX 93º 55° Parallelogram Profiling Inserts di R/L 12 r 12° 62.5° S Recommended Dimensions Tough 1 Hard Machining Data a p f Designation l di S r IC9025 IC9015 IC20 (mm) (mm/rev) KNUX 160405 R/L11 19.72 9.52 4.76 0.50 • • • 1.00-4.00 0.10-0.40 KNUX 160405 R/L12 19.72 9.52 4.76 0.50 • • 1.50-4.00 0.10-0.40 KNUX 160410 R/L11 19.72 9.52 4.76 1.00 • • 1.50-4.00 0.15-0.45 ISOTURN INSERTS KNUX 160410 R/L12 19.72 9.52 4.76 1.00 • 1.50-4.00 0.15-0.45 • For user guide and cutting speed recommendations, see pages 197-212 For tools, see pages: CKJNR/L (34) • CKNNR/L (34) 35° 72.5° VNMG-F3P 93° Double-Sided 35° Rhombic di Inserts for Semi-Finishing and 93º Finishing Applications on Steel r l S Recommended Dimensions Tough 1 Hard Machining Data a p f Designation l di S r IC8250 IC8150 IC807 (mm) (mm/rev) VNMG 160404-F3P 16.60 9.52 4.76 0.40 • • • 0.70-2.00 0.07-0.24 VNMG 160408-F3P 16.60 9.52 4.76 0.80 • • • 1.00-3.00 0.08-0.24 • For user guide and cutting speed recommendations, see pages 197-212 For tools, see pages: MVJNR/L (35) • MVVNN (36) 35° 72.5° VNMG-F3M 93° Double-Sided 35° Rhombic Inserts di for Finishing on Stainless Steel 93º r l S Recommended Dimensions Tough 1 Hard Machining Data a p f Designation l di S r IC830 IC6025 IC6015 IC806 IC807 (mm) (mm/rev) VNMG 12T302-F3M 12.40 7.15 3.97 0.20 • 0.10-1.50 0.03-0.20 VNMG 12T304-F3M 12.40 7.15 3.97 0.40 • 0.10-1.50 0.05-0.30 VNMG 12T308-F3M 12.40 7.15 3.97 0.80 • 0.10-1.50 0.05-0.30 VNMG 160404-F3M 16.60 9.52 4.76 0.40 • • • 0.10-1.50 0.05-0.30 VNMG 160408-F3M 16.60 9.52 4.76 0.80 • • • • 0.10-1.50 0.05-0.30 • For user guide and cutting speed recommendations, see pages 197-212 For tools, see pages: MVJNR/L (35) • MVVNN (36) 136 ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017