Каталог Iscar торцевые фрезы 2022 - страница 104

Навигация

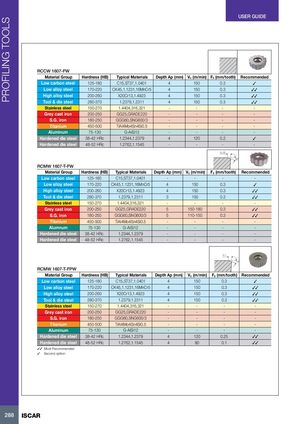

PROFILING TOOLS USER GUIDE RCCW 1607-FW Material Group Hardness (HB) Typical Materials Depth Ap (mm) Vc (m/min) Fz (mm/tooth) Recommended Low carbon steel 125-180 C15,ST37,1.0401 4 150 0.3 3 Low alloy steel 170-220 CK45,1.1231,16MnCr5 4 150 0.3 33 High alloy steel 200-260 X20Cr13,1.4923 4 150 0.3 33 Tool & die steel 280-370 1.2379,1.2311 4 150 0.3 33 Stainless steel 150-270 1.4404,316,321 - - - - Grey cast iron 200-250 GG25,GRADE220 - - - - S.G. iron 180-250 GGG60,SNG600/3 - - - - Titanium 450-500 TiAI4Mo4Sn4Si0.5 - - - - Aluminum 75-130 G-AISi12 - - - - Hardened die steel 38-42 HRc 1.2344,1.2379 4 120 0.2 3 Hardened die steel 48-52 HRc 1.2762,1.1545 - - - - 0.15 20˚ RCMW 1607-T-FW Material Group Hardness (HB) Typical Materials Depth Ap (mm) Vc (m/min) Fz (mm/tooth) Recommended Low carbon steel 125-180 C15,ST37,1.0401 - - - - Low alloy steel 170-220 CK45,1.1231,16MnCr5 4 150 0.3 3 High alloy steel 200-260 X20Cr13,1.4923 4 150 0.3 33 Tool & die steel 280-370 1.2379,1.2311 3 150 0.3 33 Stainless steel 150-270 1.4404,316,321 - - - - Grey cast iron 200-250 GG25,GRADE220 5 150-180 0.3 33 S.G. iron 180-250 GGG60,SNG600/3 5 110-150 0.3 33 Titanium 450-500 TiAI4Mo4Sn4Si0.5 - - - - Alumnum 75-130 G-AISi12 - - - - Hardened die steel 38-42 HRc 1.2344,1.2379 - - - - Hardened die steel 48-52 HRc 1.2762,1.1545 - - - - 0.1 15˚ RCMW 1607-T-FPW Material Group Hardness (HB) Typical Materials Depth Ap (mm) Vc (m/min) Fz (mm/tooth) Recommended Low carbon steel 125-180 C15,ST37,1.0401 4 150 0.3 3 Low alloy steel 170-220 CK45,1.1231,16MnCr5 4 150 0.3 33 High alloy steel 200-260 X20Cr13,1.4923 4 150 0.3 33 Tool & die steel 280-370 1.2379,1.2311 4 150 0.3 33 Stainless steel 150-270 1.4404,316,321 - - - - Grey cast iron 200-250 GG25,GRADE220 - - - - S.G. iron 180-250 GGG60,SNG600/3 - - - - Titanium 450-500 TiAI4Mo4Sn4Si0.5 - - - - Aluminum 75-130 G-AISi12 - - - - Hardened die steel 38-42 HRc 1.2344,1.2379 4 120 0.25 33 Hardened die steel 48-52 HRc 1.2762,1.1545 4 80 0.1 33 33 Most Recommended 3 Second option 288 ISCAR

Каталог Iscar сверла со сменной режущей частью 2022

Каталог Iscar сверла со сменной режущей частью 2022 Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar отрезка 2022

Каталог Iscar отрезка 2022 Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar монолитные сверла 2022

Каталог Iscar монолитные сверла 2022