Каталог Iscar расточные системы 2022 - страница 89

Навигация

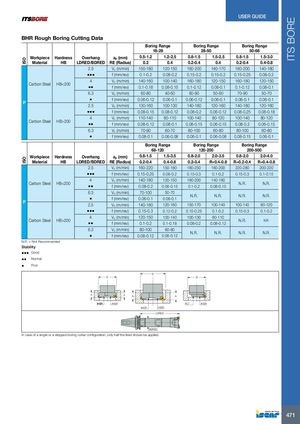

ISOISO ITS BORE USER GUIDE BHR Rough Boring Cutting Data Boring Range Boring Range Boring Range 18-28 28-50 50-68 Workpiece Hardness Overhang ap (mm) 0.5-1.2 1.2-2.5 0.8-1.5 1.5-2.5 0.8-1.5 1.5-3.0 Material HB LDRED/BDRED RE (Radius) 0.2 0.4 0.2-0.4 0.4 0.2-0.4 0.4-0.8 2.5 Vc (m/min) 150-180 120-150 160-200 140-170 160-200 140-180 ••• f (mm/rev) 0.1-0.2 0.08-0.2 0.15-0.2 0.15-0.2 0.15-0.25 0.08-0.2 Carbon Steel HB<200 4•• Vc (m/min) 140-160 100-140 160-180 120-150 160-180 120-150f (mm/rev)0.1-0.180.08-0.150.1-0.120.08-0.10.1-0.120.08-0.1 6.3 Vc (m/min) 60-80 40-60 60-90 50-60 70-90 50-70 • f (mm/rev) 0.06-0.12 0.06-0.1 0.06-0.12 0.06-0.1 0.06-0.1 0.06-0.1 P 2.5 Vc (m/min) 130-160 100-130 140-180 120-160 140-180 120-160 ••• f (mm/rev) 0.08-0.15 0.08-0.12 0.08-0.2 0.06-0.12 0.08-0.25 0.08-0.18 Carbon Steel HB>200 4•• Vc (m/min) 110-140 80-110 100-140 80-120 100-140 80-120f (mm/rev)0.08-0.120.08-0.10.08-0.150.06-0.150.08-0.20.06-0.15 6.3 Vc (m/min) 70-90 60-70 80-100 60-80 80-100 60-80 • f (mm/rev) 0.08-0.1 0.06-0.08 0.06-0.1 0.06-0.08 0.08-0.15 0.06-0.1 Boring Range Boring Range Boring Range 68-120 120-200 200-500 Workpiece Hardness Overhang ap (mm) 0.8-1.5 1.5-3.5 0.8-2.0 2.0-3.5 0.8-2.0 2.0-4.0 Material HB LDRED/BDRED RE (Radius) 0.2-0.4 0.4-0.8 0.2-0.4 R=0.4-0.8 R=0.2-0.4 R=0.4-0.8 2.5 Vc (m/min) 160-220 150-180 180-250 160-200 220-280 200-220 ••• f (mm/rev) 0.15-0.25 0.08-0.2 0.15-0.3 0.1-0.2 0.15-0.3 0.1-0.15 Carbon Steel HB<200 4•• Vc (m/min) 140-180 120-150 160-200 140-180 N.R. N.R.f (mm/rev)0.08-0.20.08-0.150.1-0.20.08-0.15 6.3• Vc (m/min) 70-100 50-70 N.R. N.R. N.R. N.R.f (mm/rev)0.06-0.10.06-0.1 P 2.5 Vc (m/min) 140-180 120-160 150-170 100-140 100-140 80-120 ••• f (mm/rev) 0.15-0.3 0.12-0.2 0.15-0.25 0.1-0.2 0.15-0.3 0.1-0.2 Carbon Steel HB>200 4•• Vc (m/min) 120-150 100-140 100-130 80-110 N.R.f (mm/rev)0.1-0.20.1-0.180.08-0.20.08-0.12N.R. 6.3• Vc (m/min) 80-100 60-80 N.R. N.R. N.R. N.R.f (mm/rev)0.08-0.120.08-0.12 N.R. = Not Recommended Stability ••• Good •• Normal • Poor Ø Ø Ø A A A1 A IHSR IHSR PLT IHSR IHCR IHSR LDRED BDRED In case of a single or a stepped boring cutter configuration, only half the feed should be applied. 471

Каталог Iscar дисковые фрезы и фрезерные пластины 2022

Каталог Iscar дисковые фрезы и фрезерные пластины 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления