Каталог Iscar расточные системы 2022 - страница 103

Навигация

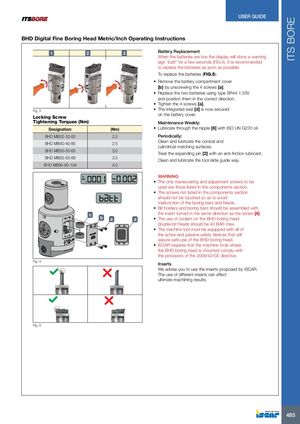

ITS BORE USER GUIDE BHD Digital Fine Boring Head Metric/Inch Operating Instructions 1 2 3 Battery Replacement When the batteries are low the display will show a warning sign “batt” for a few seconds (FIG.4). It is recommended to replace the batteries as soon as possible. To replace the batteries (FIG.5): • Remove the battery compartment cover [b] by unscrewing the 4 screws [a]. • Replace the two batteries using type SR44 1.55V and position them in the correct direction. • Tighten the 4 screws [a]. Fig. 3 • The integrated seal [d] is now secured Locking Screw on the battery cover. Tightening Torques (Nm) Maintenance Weekly: Designation: (Nm) • Lubricate through the nipple [8] with ISO UN G220 oil. BHD MB32-32-83 2.0 Periodically: BHD MB40-40-90 2.5 Clean and lubricate the conical and cylindrical matching surfaces. BHD MB50-50-60 3.0 Treat the expanding pin [2] with an anti-friction lubricant. BHD MB63-63-89 3.5 Clean and lubricate the tool slide guide way. BHD MB80-80-104 4.0 WARNING • The only maneuvering and adjustment screws to be used are those listed in the components section. • The screws not listed in the components section should not be touched so as to avoid malfunction of the boring bars and heads. • Bit holders and boring bars should be assembled with c b a the insert turned in the same direction as the screw [4].d•The use of coolant onthe BHD boringhead double-bit heads should be 40 BAR max. • The machine tool must be equipped with all of the active and passive safety devices that will assure safe use of the BHD boring head. • ISCAR requires that the machine tools where the BHD boring head is mounted comply with the provisions of the 2006/42/CE directive. Fig. 4 Inserts We advise you to use the inserts proposed by ISCAR. The use of different inserts can affect ultimate machining results. Fig. 5 485

Каталог Iscar дисковые фрезы и фрезерные пластины 2022

Каталог Iscar дисковые фрезы и фрезерные пластины 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления