Каталог Iscar обработка канавок 2022 - страница 75

Навигация

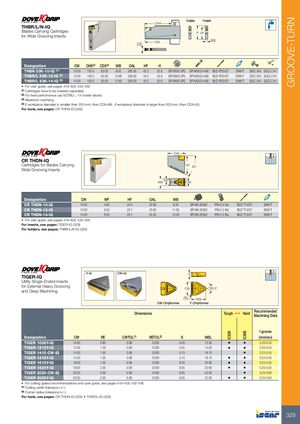

IC830 IC808 GROOVE-TURN THBN THBR OHX THBR/L/N-IQ Blades Carrying Cartridges H HF for Wide Grooving Inserts CW OAL WB Designation CW OHX(3) CDX(4) WB OAL HF H THBN 53K-10-IQ (1) 10.00 100.0 93.00 9.00 260.00 45.2 52.6 SR M5X3.5PL SR M5X23-A90 BLD IP20/S7 SW6-T SGC 340 SGCU 341 THBR/L 53K-12-IQ (2) 12.00 100.0 93.00 10.80 260.00 45.2 52.6 SR M5X3.5PL SR M5X23-A90 BLD IP20/S7 SW6-T SGC 340 SGCU 341 THBR/L 53K-14-IQ (2) 14.00 100.0 93.00 12.60 260.00 45.2 52.6 SR M5X3.5PL SR M5X23-A90 BLD IP20/S7 SW6-T SGC 340 SGCU 341 • For user guide, see pages 419-428, 432-436 (1) Cartridges have to be ordered separately. (2) For best performance use SGTBU...-14 holder blocks (3) Maximum overhang (4) If workpiece diameter is smaller than 200 mm, then CDX=98, if workpiece diameter is larger than 200 mm, then CDX=93. For tools, see pages: CR THDN-IQ (329) OAL CR THDN-IQ Cartridges for Blades Carrying HF 25° Wide Grooving Inserts WB WF CW Designation CW WF HF OAL WB CR THDN-10-IQ 10.00 4.60 24.0 22.60 9.20 SR M6-26392 PIN 5.5 INJ BLD T15/S7 SW6-T CR THDN-12-IQ 12.00 5.50 23.7 23.60 11.00 SR M6-26392 PIN 5.5 INJ BLD T15/S7 SW6-T CR THDN-14-IQ 14.00 6.50 23.7 24.20 13.00 SR M6-26392 PIN 5.5 INJ BLD T15/S7 SW6-T • For user guide, see pages 419-428, 432-436 For inserts, see pages: TIGER-IQ (329) For holders, see pages: THBR/L/N-IQ (329) TIGER-IQ S Utility Single-Ended Inserts for External Heavy Grooving CW 60.5° and Deep Machining RE INSL CW Chipformer Y Chipformer Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW RE CWTOL(1) RETOL(2) S INSL (mm/rev) TIGER 1008Y-IQ 10.00 0.80 0.08 0.050 5.05 13.30 • • 0.20-0.35 TIGER 1212Y-IQ 12.00 1.20 0.08 0.050 5.05 14.00 • • 0.20-0.40 TIGER 1415-CW-IQ 14.00 1.50 0.08 0.050 5.15 16.10 • 0.22-0.45 TIGER 1415Y-IQ 14.00 1.50 0.08 0.050 5.15 16.10 • • 0.22-0.45 TIGER 1615Y-IQ 16.00 1.50 0.08 0.050 6.35 20.00 • • 0.22-0.50 TIGER 1820Y-IQ 18.00 2.00 0.08 0.050 6.35 20.90 • • 0.25-0.55 TIGER 2020-CW-IQ 20.00 2.00 0.08 0.050 6.35 22.00 • 0.25-0.60 TIGER 2020Y-IQ 20.00 2.00 0.08 0.050 6.35 22.00 • • 0.25-0.60 • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) For tools, see pages: CR THDN-IQ (329) • THDR/L-IQ (328) 329

Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022