Каталог Iscar обработка канавок 2022 - страница 119

Навигация

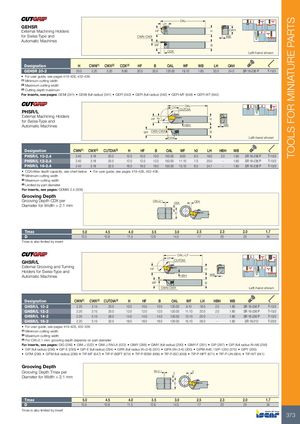

TOOLS FOR MINIATURE PARTS

OAL

LH

GEHSR

External Machining Holders HF H OAH

for Swiss-Type and CWN-CWX WB

Automatic Machines

WF B

CDX Left-hand shown

Designation H CWN(1) CWX(2) CDX(3) HF B OAL WF WB LH OAH

GEHSR 20-2 20.0 2.20 3.20 6.80 20.0 20.0 120.00 19.10 1.80 20.0 24.0 SR 16-236 P T-15/3

• For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Cutting depth maximum

For inserts, see pages: GEMI (341) • GEMI (full radius) (341) • GEPI (342) • GEPI (full radius) (342) • GEPI-MT (648) • GEPI-WT (642)

PHSR/L LH OALCUTDIA

External Machining Holdersfor Swiss-Type and HF h3 H

Automatic Machines HBH WB

WF CWX-CWX B

CDX Left-hand shown

Designation CWN(1) CWX(2) CUTDIA(3) H HF B OAL WF h3 LH HBH WB

PHSR/L 10-2.4 2.40 3.18 20.0 10.0 10.0 10.0 150.00 9.00 8.0 18.0 2.0 1.90 SR 16-236 P T-15/3

PHSR/L 12-2.4 2.40 3.18 25.0 12.0 12.0 12.0 150.00 11.10 7.0 20.0 - 1.90 SR 16-236 P T-15/3

PHSR/L 16-2.4 2.40 3.18 32.0 16.0 16.0 16.0 150.00 15.10 8.0 24.1 - 1.90 SR 16-236 P T-15/3

• CDX=Max depth capacity, see chart below • For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) Limited by part diameter

For inserts, see pages: GDMW 2.4 (306)

Grooving Depth

Grooving Depth CDX perDiameter for Width > 2.1 mm CW>2.1 CDX CDX

D

Tmax 5.0 4.5 4.0 3.5 3.0 2.5 2.3 2.0 1.7

D 10.5 10.8 11.5 12.6 14.5 17 20 25 34

Tmax is also limited by insert

OAL=LF

LH

GHSR/L CUTDIA

External Grooving and TurningHolders for Swiss-Type and HF H

Automatic Machines HBH WB

WF B

CWN-CWX Left-hand shown

Designation CWN(1) CWX(2) CUTDIA(3) H HF B OAL WF LH HBH WB

GHSR/L 10-2 2.20 3.15 20.0 10.0 10.0 10.0 120.00 9.10 18.0 2.0 1.80 SR 16-236 P T-15/3

GHSR/L 12-2 2.20 3.15 25.0 12.0 12.0 12.0 120.00 11.10 20.0 2.0 1.80 SR 16-236 P T-15/3

GHSR/L 14-2 2.20 3.15 26.0 14.0 14.0 14.0 120.00 13.10 20.0 - 1.80 SR 16-236 P T-15/3

GHSR/L 16-2 2.20 3.15 32.0 16.0 16.0 16.0 120.00 15.10 26.0 - 1.80 SR 16-212 T-20/3

• For user guide, see pages 419-428, 432-436

(1) Minimum cutting width

(2) Maximum cutting width

(3) For CW>2.1 mm: grooving depth depends on part diameter

For inserts, see pages: GIG (296) • GIM-J (522) • GIM-J-RA/LA (522) • GIMY (288) • GIMY (full radius) (290) • GIMY-F (291) • GIP (297) • GIP (full radius W

Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022