Каталог Iscar дисковые фрезы и фрезерные пластины 2022 - страница 203

Навигация

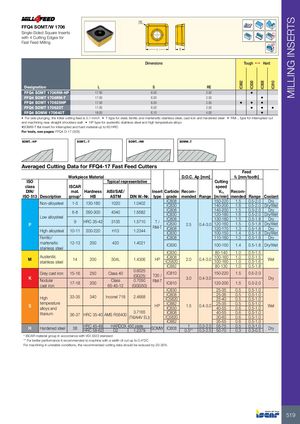

IC882 IC830 IC808 IC810 MILLING INSERTS RE FFQ4 SOMT/W 1706 Single-Sided Square Inserts Rd° with 4 Cutting Edges for Fast Feed Milling L S Dimensions Tough 1 Hard Designation L S RE FFQ4 SOMT 1706RM-HP 17.50 6.00 2.50 • FFQ4 SOMT 1706RM-T 17.50 6.00 2.50 • FFQ4 SOMT 170625HP 17.50 6.00 2.50 • • • FFQ4 SOMT 170625T 17.50 6.00 2.50 • • • FFQ4 SOMW 170640T 18.00 6.10 4.00 • • For side plunging, the initial cutting feed is 0.1 mm/t • T type for steel, ferritic and martensitic stainless steel, cast iron and hardened steel • RM-.. type for interrupted cut and machining near straight shoulders wall • HP type for austenitic stainless steel and high temperature alloys •SOMW-T flat insert for interrupted and hard material up to 60 HRC For tools, see pages: FFQ4 D-17 (303) SOMT..-HP SOMT..-T SOMT..-RM SOMW..T Averaged Cutting Data for FFQ4-17 Fast Feed Cutters Feed Workpiece Material D.O.C. Ap [mm] fz [mm/tooth] ISO Typical representstive Cutting class ISCAR speed DIN/ mat. Hardness AISI/SAE/ Insert Carbide Recom- Vc, Recom- ISO 513 Description group* HB ASTM DIN W.-Nr. type grade mended Range [m/min] mended Range Coolant Non-alloysteel 1-5 130-180 1020 1.0402 IC808IC830 150-220 1.5 0.5-2.0 Dry140-2001.60.5-2.0Dry/Wet 6-8 260-300 4340Low alloysteelP9HRC 35-423135High alloysteel10-11200-220H131.6582IC808IC830140-200 1.5 0.5-2.0 Dry120-1801.60.5-2.0Dry/Wet1.5710T/IC808IC8301.2344RM-TIC808IC830130-1801.50.5-1.8Dry2.50.4-3.0120-1601.50.5-1.8Dry/Wet120-1701.30.5-1.8Dry100-1501.40.5-1.8Dry/Wet Ferritic/ IC808 110-160 1.3 0.5-1.8 Dry martensitic 12-13 200 420 1.4021 IC830 100-150 1.4 0.5-1.8 Dry/Wet stainless steel IC830 80-140 1.0 0.5-1.5 M Austeniticstainless steel14 200 304L 1.4306 HP IC808IC5820 2.0 0.4-3.0 100-160100-160 1.01.0 0.5-1.50.5-1.6 Wet IC882 80-130 1.0 0.5-1.8 Grey cast iron 15-16 250KNodularcast iron17-18200Class 400.6025(GG25)T20 /IC810Class65-45-120.7050(GGG50)RM-TIC810150-220 1.5 0.5-2.03.00.4-3.0Dry120-2001.50.5-2.0 IC830 25-35 0.5 0.5-1.0 High 33-35 340 Inconel 718 2.4668 IC808IC5820 25-36 0.5 0.5-1.025-400.50.5-1.0 S temperaturealloys and HP IC882IC830 1.5 0.4-3.0 25-3540-55 0.50.6 0.5-1.00.5-1.0 Wet titanium 36-37 HRC 35-40 AMS R56400 3.7165(Ti6Al4V ELI) IC808IC5820 40-55 0.6 0.5-1.030-600.60.5-1.0 IC882 35-55 0.6 0.5-1.0 H Hardened steel 38 HRC 45-49HRC 58-62 HARDOX 450 plateD21.2379 SOMW IC808 1 0.3-2.5 55-750.5**0.3-2.550-70 0.50.3 0.3-1.00.3-0.5 Dry * ISCAR material group in accordance with VDI 3323 standard ** For better performance it recommended to machine with a width of cut up to 0.4*DC For machining in unstable conditions, the recommended cutting data should be reduced by 20-30% 519

Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмента для сверления

Каталог Iscar инструмента для сверления Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления