Общий каталог Ingersoll 2011 - страница 1391

Навигация

- 0003 Table of Contents

- 0006 End Mills

- 0064 Long Edge

- 0104 0Deg Face Mills

- 0160 Face Mills

- 0202 Slotters

- 0218 Form Mills

- 0236 Profile Mills

- 0302 Milling Tech

- 0384 Solid Carbide

- 0448 Solid Carbide Tech

- 0474 Holemaking & Thread Milling

- 0666 Holemaking & Thread Milling Tech

- 0720 Innofit Top On Toolholders

- 0738 HSK Toolholders

- 0774 CAT Toolholders

- 0796 BT Toolholders

- 0816 Adaptions Accessories

- 0872 Turning Inserts

- 1024 Turning Holders

- 1144 Turning Tech

- 1174 Threading Inserts

- 1242 Threading Holders

- 1256 Threading Tech

- 1268 T-Clamp

- 1344 T-Clamp Tech

- 1376 T-CAP

- 1388 T-CAP Tech

- 1394 Product_Index

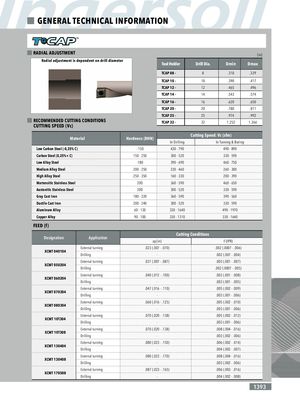

GENERAL TECHNICAL INFORMATION RADIAL ADJUSTMENT (in) Radial adjustment is dependent on drill diameter Tool Holder Drill Dia. Dmin Dmax TCAP 08 - 8 .310 .329 TCAP 10 - 10 .390 .417 TCAP 12 - 12 .465 .496 TCAP 14 - 14 .543 .574 TCAP 16 - 16 .620 .650 TCAP 20 - 20 .780 .811 TCAP 25 - 25 .974 .992 RECOMMENDED CUTTING CONDITIONS TCAP 32 - 32 1.252 1.266 CUTTING SPEED (Vc) Cutting Speed: Vc (sfm) Material Hardness (BHN) In Drilling In Turning & Boring Low Carbon Steel (-0,25% C) - 150 430 - 790 490 - 890 Carbon Steel (0,25%< C) 150 - 250 300 - 520 330 - 590 Low Alloy Steel -180 390 - 690 460 - 750 Medium Alloy Steel 200 - 250 230 - 460 260 - 300 High Alloy Steel 250 - 350 160 - 330 200 - 390 Martensitic Stainless Steel 200 360 - 590 460 - 650 Austenitic Stainless Steel 200 300 - 520 330 - 590 Gray Cast Iron 180 - 220 360 - 590 390 - 560 Ductile Cast Iron 200 - 240 300 - 520 330 - 590 Aluminum Alloy 60 - 130 330 - 1640 490 - 1970 Copper Alloy 90 - 100 330 - 1310 330 - 1640 FEED (f) Cutting Conditions Designation Application ap (in) f (IPR) External turning .023 (.007 - .070) .002 (.0007 - .006) XCMT 040104 Drilling - .002 (.007 - .004) External turning .031 (.007 - .087) .003 (.001 - .007) XCMT 050204 Drilling - .002 (.0007 - .005) External turning .040 (.012 - .100) .003 (.001 - .008) XCMT 060204 Drilling - .003 (.001 - .005) External turning .047 (.016 - .110) .005 (.002 - .009) XCMT 070304 Drilling - .003 (.001 - .006) External turning .060 (.016 - .125) .005 (.002 - .010) XCMT 080304 Drilling - .003 (.001 - .006) External turning .070 (.020 - .138) .005 (.002 - .012) XCMT 10T304 Drilling - .003 (.001 - .006) External turning .070 (.020 - .138) .008 (.004 - .016) XCMT 10T308 Drilling - .003 (.002 - .006) External turning .080 (.023 - .150) .006 (.002 - .014) XCMT 130404 Drilling - .004 (.002 - .007) External turning .080 (.023 - .170) .008 (.004 - .016) XCMT 130408 Drilling - .003 (.002 - .006) External turning .087 (.023 - .165) .006 (.003 - .016) XCMT 170508 Drilling - .004 (.002 - .008) 1393

Общий каталог Ingersoll 2016 - 2017

Общий каталог Ingersoll 2016 - 2017 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014 Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Общий каталог Ingersoll 2013 - 2014

Общий каталог Ingersoll 2013 - 2014 Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021