Общий каталог Harlingen 2024 - страница 151

Навигация

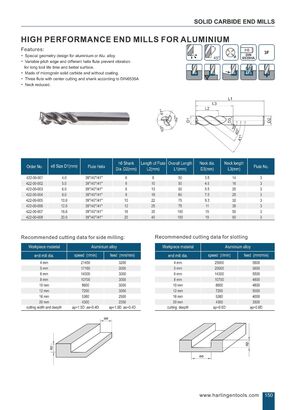

SOLID CARBIDE END MILLS HIGH PERFORMANCE END MILLS FOR ALUMINIUM £ Features : • Special geometry design for aluminium or Alu. alloy. • Variable pitch edge and different helix flute prevent vibration for long tool life time and better surface. • Made of micrograin solid carbide and without coating. • Three flute with center cutting and shank according to DIN6535A • Neck reduced. \ h6 3F DIN * V 6535HAv L1 L3 L2 Q Order No. e8 SizeD1(mm) 422-00-001 422-00-002 422-00-003 422-00-004 422-00-005 422-00-006 422-00-007 422-00-008 4.0 5.0 6.0 8.0 10.0 12.0 16.0 20.0 Flute Helix Length of Flute Overall Length h6 Shank L2(mm) L1(mm) Dia .D2(mm) 39°/40°/41° 39°/40°/41° 39°/40°/41° 39°/40°/41° 39°/40°/41° 39740°/41° 6 8 6 10 13 18 22 25 35 40 6 8 10 12 16 20 39740741° 39740741° Recommended cutting data for side milling: Workpiece material Aluminium alloy 50 50 50 60 75 75 100 100 " CNJ 0 Neck dia. D 3(mm) Neck length L3(mm) Flute No. 3.5 4.5 5.5 7.5 9.3 11 15 19 14 16 20 25 32 35 50 50 3 3 3 3 3 3 3 3 Recommended cutting data for slotting Workpiece material Aluminium alloy end mill dia. speed (r/min) feed (mm/min) end mill dia. speed (r/min) feed (mm/min) 4 mm 5 mm 6 mm 8 mm 10 mm 12 mm 16 mm 20 mm cutting width and deepth 21450 17160 14300 10700 8600 7200 5380 4300 ap=1.5D ae=0.4D 3200 3000 3000 3000 3000 3000 2500 2200 ap=1.5D ae=0.4D 4 mm 5 mm 6 mm 8 mm 10 mm 12 mm 16 mm 20 mm cutting deepth 25000 20000 14300 10700 8600 7200 5380 4300 ap=0.6D 5800 5600 5500 4800 4800 5000 4000 3500 ap=0.6D ae roGi www. harlingentools . com 150

Каталог Harlingen самоцентрирующиеся тиски и системы нулевого базирования

Каталог Harlingen самоцентрирующиеся тиски и системы нулевого базирования Каталог Harlingen системы нулевого базирования

Каталог Harlingen системы нулевого базирования Каталог Harlingen инструмент для пресс-форм 2024

Каталог Harlingen инструмент для пресс-форм 2024 Каталог Harlingen PSC-оправки (CAPTO совместимые)

Каталог Harlingen PSC-оправки (CAPTO совместимые) Каталог Harlingen статические держатели режущих инструментов блочного типа

Каталог Harlingen статические держатели режущих инструментов блочного типа