Общий каталог Harlingen 2024 - страница 110

Навигация

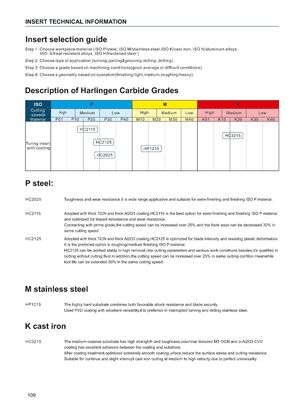

INSERT TECHNICAL INFORMATION Insert selection guide Step 1 : Choose workpiece material ( ISO P / steel , ISO M / stainless steel , ISO K / cast iron , ISO N / aluminum alloys , ISO S/ heat resistant alloys , ISO H / hardened steel ) . Step 2 : Choose type of application ( turning , parting & grooving , milling drilling ) . Step 3 : Choose a grade based on machining conditions ( good , average or difficult conditions ) . Step 4 : Chosse a geometry based on operation (finishing / light , medium ,roughing / heavy ) . Description of Harlingen Carbide Grades ISO Cutting speeds Material P High P 01 M Medium P 10 P 20 High Low P 30 P 40 M 10 M 20 K Medium Low M 30 M 40 High K 01 Medium K 10 K 20 Low K 30 K 40 H 32115 HC 3215 HQ 2125 Turing insert with coating HP1215 H C 2025 P steel: HC 2025 Toughness and wear resistance.lt is wide range applicative and suitable for semi-finishing and finishing ISO P material. HC 2115 Adopted with thick TiCN and thick AI203 coating ,HC2115 is the best option for semi-finishing and finishing ISO P material , and optimized for impact rersistance and wear resistance. Contracting with prime grade ,the cutting speed can be increased over 25% and the flank wear can be decreased 30% in same cutting speed. HC 2125 Adopted with thick TiCN and thick AI203 coating ,HC2125 is optimized for blade intensity and resisting plastic deformation. It is the preferred option in roughing/medium finishing ISO P material. HC 2125 can be worked stably in high removal rate cutting parameters and serious work conditions. besides,it's qualified in cutting without cutting fluid.in addition ,the cutting speed can be increased over 25% in same cutting confiton meanwhile tool life can be extended 50% in the same cutting speed. M stainless steel HP 1215 The highly hard substrate combines both favorable shock resistance and blade security. Used PVD coating with excellent versatility,it is preferred in interrupted turning and milling stainless steel. K cast iron HC 3215 109 The medium-coasrse substrate has high strenghth and toughness, columnar textured MT-TiCN and a-AI203 CVD coating has excellent adhesion between the coating and substrate. After coating treatment ,optimized extremely smooth coating urface, reduce the surface stress and cutting resistance. Suitable for continue and slight interrupt cast iron cutting at medium to high velocity due to perfect universality.

Каталог Harlingen самоцентрирующиеся тиски и системы нулевого базирования

Каталог Harlingen самоцентрирующиеся тиски и системы нулевого базирования Каталог Harlingen системы нулевого базирования

Каталог Harlingen системы нулевого базирования Каталог Harlingen инструмент для пресс-форм 2024

Каталог Harlingen инструмент для пресс-форм 2024 Каталог Harlingen PSC-оправки (CAPTO совместимые)

Каталог Harlingen PSC-оправки (CAPTO совместимые) Каталог Harlingen статические держатели режущих инструментов блочного типа

Каталог Harlingen статические держатели режущих инструментов блочного типа